Introduction

In recent years, 3D printing has witnessed a remarkable surge in its applications across various industries. From manufacturing intricate aerospace components to creating customized medical implants, the versatility of 3D printing technology is reshaping the industrial landscape. The global 3D printing market size was valued at \(15.3 billion in 2020 and is projected to reach \)51.4 billion by 2026, growing at a CAGR of 22.3% from 2021 to 2026, according to a report by Grand View Research. This exponential growth is a testament to its increasing importance.

Behind the scenes of every successful 3D printing project, there stands a crucial figure - the 3D printing specialist. They are the masterminds who transform ideas into tangible 3D printed objects, ensuring that every layer is laid down with precision. If you're considering venturing into the world of 3D printing, whether for business or personal projects, you might have numerous questions about 3D printing specialists. In this article, we will explore everything you need to know, from their roles and skills to how to choose the right one for your needs.

Who is a 3D Printing Specialist?

Definition and Core Competencies

A 3D printing specialist can be defined as a professional who has in - depth knowledge and skills in the field of 3D printing technology, capable of managing and optimizing the entire 3D printing process.

One of their core competencies is proficiency in multiple 3D printing technologies. For instance, Fused Deposition Modeling (FDM), which is one of the most common 3D printing techniques. FDM printers work by heating and extruding thermoplastic filaments layer by layer to build an object. Specialists need to understand its working mechanism thoroughly, such as how to adjust the temperature of the nozzle to ensure smooth extrusion and proper adhesion between layers. Stereolithography (SLA) is another important technology. It uses ultraviolet light to cure liquid resin layer by layer, enabling the creation of high - precision models with smooth surfaces. A 3D printing specialist should be able to operate SLA printers, choosing the right resin materials according to different project requirements.

Mastery of 3D modeling software is also essential. Software like Computer - Aided Design (CAD) allows specialists to create and modify 3D models with precision. They can design complex geometries, adjust dimensions, and perform simulations to ensure the functionality and manufacturability of the models. For example, in the aerospace industry, 3D printing specialists use CAD software to design lightweight and high - strength components with intricate internal structures.

Moreover, a solid understanding of materials is a must. 3D printing materials range from plastics such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) to metals like titanium and aluminum. Specialists need to know the properties of each material, including strength, heat resistance, and chemical resistance, to select the most suitable one for a particular project. For example, in medical applications, biocompatible materials like certain types of plastics are used for 3D - printed implants, and the specialist must ensure the material meets all medical standards.

Educational Background and Experience

Typically, 3D printing specialists hold degrees in relevant fields such as mechanical engineering, materials science, or industrial design. A mechanical engineering degree provides a solid foundation in engineering principles, including mechanics, thermodynamics, and manufacturing processes, which are crucial for understanding the operation and optimization of 3D printers. Materials science degrees, on the other hand, focus on the study of materials' properties, structures, and applications, equipping specialists with the knowledge to select and work with different 3D printing materials.

Industry experience is equally important. Years of hands - on experience enable specialists to handle various challenges that may arise during the 3D printing process. For example, they can quickly troubleshoot issues such as nozzle clogging in FDM printers or uneven curing in SLA printers. Participation in complex projects is also a significant advantage. A 3D printing specialist who has worked on large - scale projects, like 3D - printing entire building components or developing custom - made prosthetics for patients, has a broader perspective and more comprehensive skills. They have learned how to collaborate with different teams, manage project timelines, and ensure the quality of the final 3D - printed products.

Services Offered by 3D Printing Specialists

3D printing specialists offer a wide range of services that cater to various industries and project requirements. These services take full advantage of the unique capabilities of 3D printing technology.

Prototyping Services

One of the primary services provided by 3D printing specialists is prototyping. In the past, creating a product prototype often involved time - consuming and costly processes such as CNC machining or injection molding. For example, in the automotive industry, traditional prototyping of a new car part could take weeks and cost thousands of dollars. However, 3D printing specialists can turn a digital design into a physical prototype in a matter of hours or days.

The cost - effectiveness of 3D printing for prototyping is remarkable. A study by Wohlers Associates found that for low - volume prototyping (less than 50 units), 3D printing can be up to 50% cheaper than traditional methods. This is because 3D printing eliminates the need for expensive molds and tooling.

3D printing also allows for rapid iteration. Designers can quickly make changes to the digital model and print a new prototype, which is crucial for product development. In the consumer electronics industry, companies like Apple can use 3D - printed prototypes to test different designs of their products, ensuring that the final product meets both functional and aesthetic requirements before mass production.

Custom Manufacturing

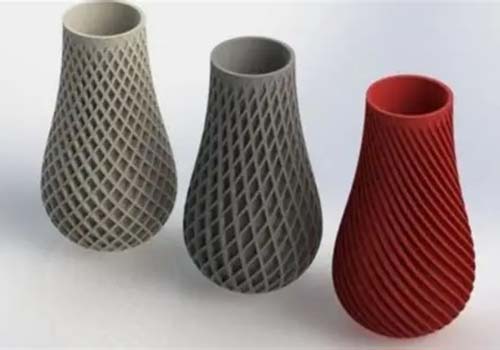

3D printing specialists are well - equipped to handle custom manufacturing. They can produce small - batch, complex, or highly personalized products with ease. For instance, in the jewelry industry, customers may want unique, one - of - a - kind pieces. 3D printing specialists can create intricate jewelry designs, such as a necklace with a personalized pattern, that would be extremely difficult and expensive to produce using traditional manufacturing methods.

When comparing 3D printing for custom manufacturing with large - scale traditional manufacturing, the differences are significant:

| Comparison Aspect | 3D Printing for Custom Manufacturing | Large - scale Traditional Manufacturing |

| Flexibility | High flexibility, can produce unique designs with ease | Limited flexibility, better for standardized products |

| Cost for Small Batches | Lower cost as it avoids high setup costs | High cost due to high setup and tooling costs |

| Production Time for Small Batches | Shorter production time | Longer production time due to setup and production line processes |

| Complexity of Design | Can handle highly complex designs | Difficult and costly to produce complex designs |

Material Selection and Optimization

Selecting the right material is crucial for the success of a 3D printing project, and 3D printing specialists play a key role in this aspect. There are numerous materials available for 3D printing, each with its own unique properties:

- PLA (Polylactic Acid): A biodegradable plastic made from renewable resources like corn starch or sugarcane. It has a relatively low melting point, making it easy to print. PLA is often used for creating 3D - printed artworks, educational models, and simple consumer products due to its good printability and environmental friendliness.

- ABS (Acrylonitrile Butadiene Styrene): A strong and durable thermoplastic. ABS has a higher heat resistance compared to PLA and is suitable for applications where strength is required, such as in the production of functional prototypes for mechanical parts or electronic enclosures.

- Titanium: A lightweight and extremely strong metal with excellent corrosion resistance. In the aerospace and medical industries, 3D - printed titanium parts are used for components like aircraft engine parts and dental implants, respectively.

3D printing specialists can also optimize material use to reduce costs. They can use software to analyze the stress distribution in a 3D model and adjust the internal structure of the object. For example, instead of printing a solid object, they can create a lattice - like internal structure. This not only reduces the amount of material used but also maintains the object's structural integrity. A case study by GE Aviation showed that by using 3D printing and optimizing material use, they were able to reduce the weight of a fuel nozzle by 25% while improving its performance, resulting in significant cost savings in both material and fuel consumption over the long run.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the role of 3D printing specialists in product innovation and optimizing production processes. In the 3D printing field, we provide a wide range of services, from polymer 3D printing for creating detailed and lightweight plastic components to metal 3D printing for producing high - strength metal parts.

Our team understands the importance of 3D printing specialists in material selection and process optimization. We also offer training services to help clients better understand and utilize 3D printing technology. We believe in building long - term partnerships with our clients, and our 3D printing - related services are designed to support their projects from concept to completion. Whether it's a small - scale custom project or a large - scale production requirement, Yigu Technology is committed to leveraging 3D printing technology with the help of 3D printing specialists to meet the diverse needs of our clients.