Introduction

Definition and Basics of 3D Metal Printing

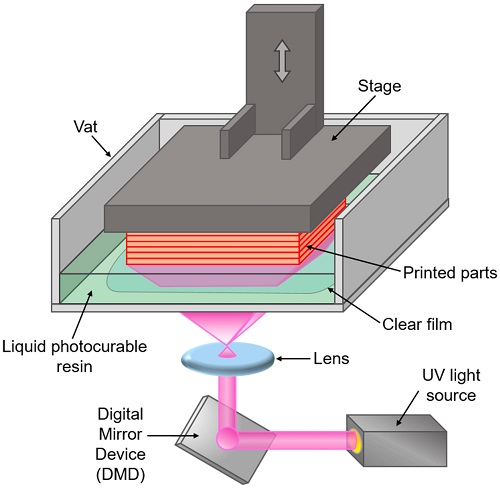

3D metal printing, also known as metal additive manufacturing, is a revolutionary technology that has been making waves in the UK and around the world. At its core, it is a process of creating three - dimensional objects by adding layers of metal material, one on top of the other. This is a stark contrast to traditional manufacturing methods, which often involve subtracting material through processes like cutting, milling, or drilling.

The process begins with a digital model file, typically created using computer - aided design (CAD) software or obtained from a 3D scanner. This digital model serves as the blueprint for the final product. The 3D printer then reads the data from the digital model and starts depositing metal material layer by layer. Each layer is a cross - section of the final object, and as the layers accumulate, the three - dimensional shape is gradually formed.

Common metal materials used in 3D metal printing include titanium, stainless steel, aluminum, and nickel - based alloys. These materials offer a range of properties such as high strength, corrosion resistance, and heat resistance, making 3D - printed metal objects suitable for a wide variety of applications. For example, in the aerospace industry, titanium 3D - printed parts are used due to their high strength - to - weight ratio, which helps in reducing the overall weight of aircraft and improving fuel efficiency. In the medical field, 3D - printed stainless - steel implants can be customized to fit a patient's unique anatomy.

Applications of 3D Metal Printing in the UK

3D metal printing has found a wide range of applications across various industries in the UK, revolutionizing the way products are designed and manufactured. Here are some of the key sectors where it is making a significant impact:

Automotive Industry

In the automotive industry, 3D metal printing is being increasingly used to enhance performance and reduce production costs. For engine components, 3D - printed metal parts can be designed with complex internal geometries that are impossible to achieve through traditional manufacturing methods. These optimized designs improve fuel efficiency and engine power. For example, some UK - based automotive companies are using 3D - printed metal intake manifolds. By having a more efficient flow design, the engine can draw in air more effectively, resulting in better combustion and increased horsepower.

Lightweight structures are also a major focus in the automotive industry. With the use of 3D - printed metal parts, car manufacturers can reduce the overall weight of the vehicle without sacrificing strength. McLaren, a well - known British automotive company, has been exploring the use of 3D - printed metal components in its high - performance cars. By replacing some traditional parts with 3D - printed metal equivalents, they have managed to improve the power - to - weight ratio, leading to better acceleration and handling.

Aerospace Sector

The aerospace sector in the UK has been at the forefront of adopting 3D metal printing technology. Components in aircraft need to meet strict requirements of high strength and low weight. 3D - printed metal parts are ideal for this purpose. For instance, 3D - printed titanium brackets are being used in aircraft structures. These brackets can be designed to have a lattice - like internal structure, which reduces weight while maintaining the necessary strength to withstand the mechanical stresses during flight.

Rolls - Royce, a leading aerospace company in the UK, has made significant progress in using 3D metal printing for its jet engine components. By 3D - printing parts such as turbine blades, they can create more efficient cooling channels within the blades. This allows the engine to operate at higher temperatures, increasing fuel efficiency and thrust, while also reducing emissions.

Healthcare Field

In the healthcare field, 3D metal printing is transforming patient care. One of the most significant applications is in the production of personalized prosthetics. Each patient has a unique body shape and movement patterns, and 3D - printed metal prosthetics can be customized to fit perfectly. For example, in some UK hospitals, 3D - printed metal prosthetic limbs are being used. These prosthetics are designed based on a patient's 3D - scanned residual limb, ensuring a better fit and more natural movement.

3D - printed metal implants are also becoming more common. Hip and knee implants can be custom - made to match a patient's bone structure. This reduces the risk of implant rejection and improves the long - term success of the surgery. The Royal National Orthopaedic Hospital in the UK has been using 3D - printed metal implants in some of its orthopedic procedures, with positive results in terms of patient recovery and quality of life.

Yigu Technology's View

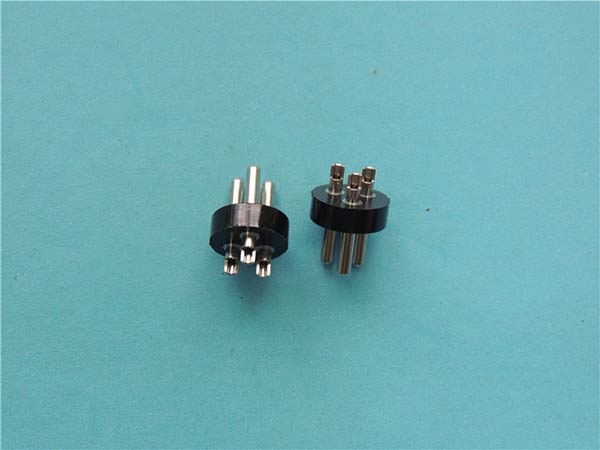

As a non - standard plastic and metal products custom supplier, Yigu Technology firmly believes that 3D metal printing holds great promise in the field of metal product customization. The technology allows for the realization of intricate designs that are otherwise impossible with traditional manufacturing methods. This means that unique and complex metal parts can be produced to meet the highly individualized needs of customers.

For instance, in some special - shaped mechanical parts or customized jewelry, 3D metal printing can accurately reproduce the design concept. Although there are challenges such as high material costs and relatively slow printing speed, Yigu Technology is optimistic about its long - term development potential. With the continuous progress of technology, these issues are expected to be gradually resolved, making 3D metal printing an even more attractive option for metal product customization.

FAQ

What are the most common metals used in 3D printing in the UK?

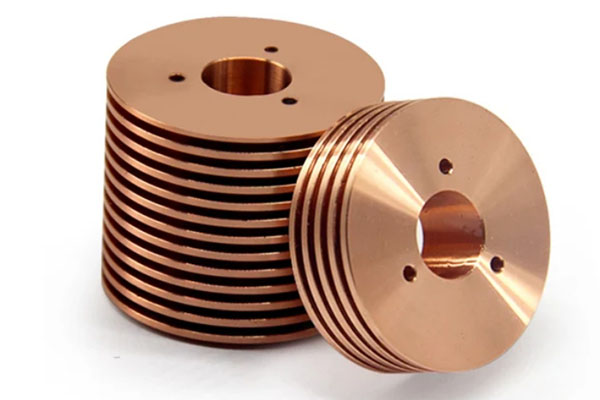

In the UK, some of the most common metals used in 3D printing include stainless steel, titanium alloy, and aluminum alloy. Stainless steel, like 316L and 17 - 4PH, is popular due to its corrosion resistance and good mechanical properties. It is widely used in the food and beverage industry for equipment parts and in the marine industry for components exposed to water. Titanium alloy, especially Ti - 6Al - 4V, offers a high strength - to - weight ratio, making it ideal for aerospace applications, such as aircraft engine components and structural parts. Aluminum alloy, such as AlSi10Mg, is favored for its lightweight nature and good thermal conductivity. It is often used in the automotive industry for engine parts and in the electronics industry for heat sinks.

How accurate is 3D metal printing in the UK?

The accuracy of 3D metal printing in the UK depends on several factors, including the type of 3D printer, the printing process, and the metal material used. Generally, in the powder - bed fusion process, which is commonly used for 3D metal printing, the accuracy can range from ±0.1mm to ±0.05mm for small - to - medium - sized parts. For example, in the production of small metal components for jewelry or precision mechanical devices, printers with high - end technology can achieve tolerances as low as ±0.05mm. However, for larger parts, the accuracy may be slightly lower, around ±0.1mm. This is because larger parts are more likely to be affected by factors such as thermal stress during the printing process.

What is the typical cost of 3D metal printing services in the UK?

The cost of 3D metal printing services in the UK is composed of multiple elements, including equipment cost, material cost, and labor cost. For small - scale, low - complexity parts, if using common materials like aluminum alloy, the cost might start from £50 - £100 per part. This includes the cost of the metal powder, the operation of the 3D printer, and basic post - processing. For more complex parts with high - performance materials such as titanium alloy, and larger sizes, the cost can be significantly higher. For instance, a complex aerospace - grade titanium part could cost several hundred to thousands of pounds, considering the high - cost of titanium powder, longer printing time, and more elaborate post - processing requirements.