What is 3D Printing for Mechanical Parts?

3D printing, also known as additive manufacturing, for mechanical parts is a revolutionary technology that creates three - dimensional components directly from a digital file. It's a far - cry from traditional manufacturing methods like subtractive machining (where material is removed from a larger block) or casting.

To better understand the concept, think of baking a loaf of bread. Instead of taking a large block of dough and carving away the parts you don't need (subtractive), with 3D printing, you're building the loaf layer by layer. You start with a recipe (the digital model), and then, ingredient by ingredient (layer by layer of material), you construct the final product.

The process begins with creating a 3D model. This can be done using computer - aided design (CAD) software, where engineers precisely define the shape, dimensions, and internal structures of the mechanical part. For example, if designing a custom - made gear, the CAD model will detail the tooth profile, the bore diameter, and any additional features like keyways.

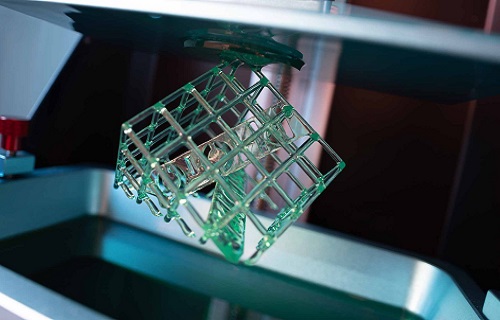

Once the 3D model is ready, it is sliced into thin cross - sectional layers by specialized software. These layers are then sent to the 3D printer. The printer reads the data and deposits the material, layer upon layer, to gradually build the physical part. There are various types of 3D printers, each using different materials and techniques. For instance, fused deposition modeling (FDM) printers extrude a melted thermoplastic filament, such as ABS or PLA, through a nozzle. As the filament cools, it solidifies, bonding to the previous layer. Stereolithography (SLA) printers, on the other hand, use a photosensitive resin that is cured layer by layer under ultraviolet light.

After the printing process is complete, the part often requires post - processing. This can include removing support structures (which were used to hold the part during printing), sanding to smooth the surface, and heat - treating to improve material properties. For example, metal 3D - printed parts might need heat - treatment to relieve internal stresses and enhance their strength.

Materials Used in 3D Printing Mechanical Parts

Thermoplastics

Thermoplastics are a popular choice for 3D printing mechanical parts due to their ease of use and relatively low cost. Polylactic acid (PLA) is one of the most common thermoplastics used in 3D printing. It is biodegradable and derived from renewable resources such as corn starch or sugarcane. PLA has a low melting point, typically around 170 - 180°C, which makes it easy to print with. It also has good dimensional stability, resulting in accurate and detailed parts. PLA is often used for creating prototypes, small consumer products, and decorative items. For example, in the consumer electronics industry, PLA can be used to print custom - made phone case prototypes, where its ease of printing and relatively low cost allow for quick design iterations.

Acrylonitrile Butadiene Styrene (ABS) is another widely used thermoplastic. It has higher strength and heat resistance compared to PLA, with a heat - deflection temperature around 90 - 110°C. ABS can withstand more mechanical stress and is suitable for applications where durability is crucial. It is commonly used in the automotive and aerospace industries for making parts like interior components, brackets, and small structural elements. For instance, in the automotive industry, ABS can be 3D - printed into small brackets that hold electrical components in place within the vehicle, thanks to its strength and heat resistance properties. However, ABS has some drawbacks, such as a tendency to warp during printing and a strong odor when heated.

Metals

Metal 3D printing has opened up new possibilities for manufacturing high - performance mechanical parts. Stainless steel is a popular metal choice. It offers excellent corrosion resistance, high strength, and good fatigue resistance. Stainless steel 3D - printed parts can be found in various industries, including food processing, chemical, and medical. In the food processing industry, stainless steel 3D - printed valves and fittings are used because they can resist corrosion from food - based chemicals and cleaning agents while maintaining their structural integrity.

Titanium alloy is highly valued in the aerospace and medical industries. It has a low density, high strength - to - weight ratio, and outstanding corrosion resistance. In aerospace, titanium alloy 3D - printed parts are used in aircraft engines and airframe structures. For example, components in the engine's compressor section can be 3D - printed from titanium alloy. These parts need to withstand high temperatures, extreme mechanical stress, and corrosive environments during flight, and titanium alloy's properties make it an ideal material for such applications. However, metal 3D printing is generally more expensive and requires more complex equipment and post - processing compared to thermoplastic 3D printing.

Composites

Composites combine the advantages of different materials to achieve unique properties. Carbon fiber - reinforced plastics (CFRP) are widely used in applications that require high strength and low weight. Carbon fibers provide high tensile strength and stiffness, while the plastic matrix holds the fibers together and distributes the load. CFRP is commonly used in the aerospace, automotive, and sports equipment industries. In the aerospace industry, CFRP can be 3D - printed into wing components. The high strength - to - weight ratio of CFRP allows for the creation of lighter yet stronger wings, which can improve fuel efficiency and aircraft performance. In the automotive industry, CFRP can be used to print lightweight body panels or chassis components, reducing the vehicle's overall weight and improving fuel economy. However, 3D printing composites can be challenging due to the complex interaction between the fibers and the matrix, and it often requires specialized printing techniques and equipment.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology acknowledges the remarkable potential of 3D printing for mechanical parts. The technology aligns well with our commitment to customization, as it enables the production of highly specialized components that meet unique client requirements.

3D printing has opened up new possibilities for creating complex geometries and optimizing part designs, which is in line with our goal of providing innovative solutions. We see great potential in using 3D printing for rapid prototyping, allowing our clients to test and refine their designs more efficiently.

However, we also recognize the challenges that come with 3D printing, such as material limitations and the need for high - precision post - processing in some cases. At Yigu Technology, we are constantly exploring ways to overcome these challenges. We invest in advanced materials research to expand the range of printable materials and improve their performance. Our team of experts is also dedicated to optimizing the 3D printing process and post - processing techniques to ensure the highest quality of the final products. We believe that by combining our expertise in custom manufacturing with the capabilities of 3D printing, we can offer more value - added services to our clients and contribute to the development of the mechanical parts manufacturing industry.

FAQ

What are the most common 3D printing technologies for mechanical parts?

- Fused Deposition Modeling (FDM): This is one of the most accessible 3D printing technologies. It works by heating a thermoplastic filament, such as ABS or PLA, until it melts. The melted filament is then extruded through a nozzle and deposited layer by layer to build the part. FDM is popular for its simplicity, low cost, and wide range of available materials. It is often used for prototyping, creating small consumer products, and educational purposes.

- Stereolithography (SLA): SLA uses a photosensitive resin. An ultraviolet (UV) laser traces the cross - section of the part onto the surface of the liquid resin, curing it and solidifying it layer by layer. This technology offers high precision and smooth surface finishes, making it suitable for creating detailed models, jewelry, and dental applications.

- Selective Laser Sintering (SLS): In SLS, a laser is used to sinter powdered materials, such as plastic, metal, or ceramic, together. The laser selectively fuses the powder particles in each layer according to the 3D model, and the unsintered powder supports the part during the printing process. SLS can produce strong, functional parts with complex geometries and is commonly used in the automotive, aerospace, and tooling industries.

How accurate are 3D printed mechanical parts?

The accuracy of 3D printed mechanical parts can vary depending on several factors, including the 3D printing technology used, the quality of the printer, the material, and the printing parameters. Generally, consumer - grade FDM printers can achieve an accuracy of around ±0.1 - 0.4 mm. Industrial - grade FDM printers can be more accurate, with tolerances as low as ±0.05 mm. SLA printers typically offer higher accuracy, often in the range of ±0.05 - 0.15 mm. SLS - printed parts can have an accuracy of about ±0.1 - 0.3 mm.

To improve the accuracy of 3D printed parts, the following methods can be considered:

- Proper calibration of the printer: Regularly calibrate the printer to ensure that the axes move accurately and that the extruder (for FDM) or laser (for SLA and SLS) is properly aligned.

- Optimization of printing parameters: Adjust parameters such as layer height, print speed, and temperature to achieve better dimensional accuracy. For example, using a smaller layer height can result in more detailed and accurate parts, although it may increase the printing time.

- Post - processing: Operations like sanding, machining, and heat - treating can be used to further improve the accuracy and surface finish of the printed parts.

Can 3D printed mechanical parts meet high - strength requirements?

Yes, 3D printed mechanical parts can meet high - strength requirements, depending on the materials and printing processes used. For example, metal 3D printing technologies, such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), can produce parts with high strength and excellent mechanical properties. Stainless steel, titanium alloy, and aluminum alloy parts printed using these methods are used in aerospace, automotive, and other high - performance applications.

In the aerospace industry, 3D - printed titanium alloy parts are used in aircraft engines and structural components. These parts can withstand high temperatures, extreme mechanical stress, and corrosive environments. For thermoplastics, materials like polyetheretherketone (PEEK) have high strength, heat resistance, and chemical resistance. PEEK 3D - printed parts can be used in applications where high - strength plastics are required, such as in some medical devices and industrial machinery components. However, it's important to note that the mechanical properties of 3D - printed parts can be affected by factors like the printing orientation, porosity, and post - processing treatments.