What is SLA Printing Service?

SLA printing service, short for Stereolithography Apparatus printing service, is one of the earliest and most versatile 3D printing technologies. It has been revolutionizing the manufacturing and prototyping industries since its invention.

How SLA Printing Works

At its core, SLA uses a high - precision ultraviolet (UV) laser to cure layers of photosensitive resin. First, a 3D model is created using computer - aided design (CAD) software. This model is then sliced into thin layers, usually ranging from 0.05 to 0.1 mm thick. The SLA printer projects the shape of each layer onto the surface of a liquid resin vat using the UV laser. As the laser hits the resin, it solidifies the resin in the shape of the layer, bonding it to the previously cured layer. Once a layer is fully cured, the build platform moves down slightly, and a new layer of resin is spread over the previously cured layer. This process repeats layer by layer until the entire 3D object is completed.

Advantages of SLA Printing Service

- High Precision: SLA printers can achieve very high levels of precision, often with tolerances as low as ±0.05 mm. This makes it ideal for applications where intricate details are crucial, such as jewelry design, dental prosthetics, and micro - mechanical parts. For example, in jewelry design, SLA printing can create complex and delicate patterns that would be extremely difficult to achieve through traditional manufacturing methods.

- Smooth Surface Finish: The cured resin layers in SLA printing result in a relatively smooth surface finish compared to some other 3D printing technologies. This reduces the need for extensive post - processing, saving both time and cost. In the production of small figurines or prototypes for consumer products, the smooth surface gives a more professional and market - ready appearance.

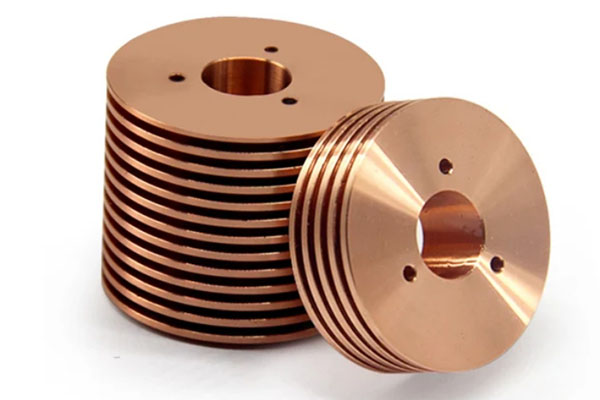

- Versatile Material Options: There is a wide range of photosensitive resins available for SLA printing. These resins can have different properties, such as high strength, flexibility, heat resistance, and biocompatibility. For instance, biocompatible resins are used in medical applications like creating custom - fit orthodontic models or surgical guides, while heat - resistant resins are suitable for parts that will be exposed to high - temperature environments.

How Does SLA Printing Service Work?

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values SLA printing service. In small - batch custom production, SLA printing shines. It allows for the quick production of a small number of customized parts without the need for expensive molds, which significantly reduces production costs and lead times. For example, when creating custom - designed electronic device casings in small quantities, SLA printing can rapidly turn the design into a physical product for testing and market - entry evaluation.

Moreover, SLA's ability to handle complex geometries is a game - changer. It can produce parts with intricate internal structures, undercuts, and fine details that are nearly impossible to achieve through traditional manufacturing methods. In the production of non - standard plastic components with complex flow channels or lattice - like internal structures, SLA printing enables the realization of these complex designs, enhancing product functionality. This technology has opened up new possibilities for Yigu Technology to meet the diverse and unique needs of its customers.

FAQs about SLA Printing Service

What is the typical turnaround time for an SLA printing service?

The typical turnaround time for an SLA printing service can vary. In general, for small and relatively simple parts, it can be as short as 1 - 3 days. This is because the printing process itself doesn't take too long, and there is less post - processing required. However, for larger or more complex models, the turnaround time may extend to 5 - 7 days. Complex models often need more time for the printer to complete the detailed layers, and the post - processing, such as removing supports and surface finishing, also takes longer. Additionally, factors like the availability of the printer, the workload of the service provider, and the need for additional services (such as custom coloring or advanced surface treatments) can further affect the turnaround time.

How much does an SLA printing service usually cost?

The cost of an SLA printing service is determined by multiple factors. Material cost is a significant component. Different types of photosensitive resins have different prices. For example, high - performance resins with special properties like heat resistance or biocompatibility are more expensive than standard resins. A small model printed with a common resin might cost around \(20 - \)50 in material, while a model using a specialized resin could have a material cost of \(100 or more. **Equipment cost** also plays a role. High - precision SLA printers are costly to purchase and maintain, and these costs are factored into the service price. Printers with better resolution and larger build volumes generally result in higher service charges. **Model complexity and size** are crucial. Complex models with intricate details, multiple parts, or a large number of overhangs require more time to print and more support structures, increasing the cost. A simple cube - shaped model might cost \)30 - \(50, while a highly detailed and complex mechanical part could cost \)200 - $500 or even more. Post - processing requirements can add to the cost. If the model needs extensive sanding, polishing, or painting, these additional services will increase the overall price.

Can SLA printing service handle large - scale production?

SLA printing service has both advantages and limitations when it comes to large - scale production. Advantages: SLA can produce parts with high precision and excellent surface finish, which is beneficial for large - scale production of high - quality products where details matter, such as in the production of high - end consumer electronics components or luxury goods prototypes. It also allows for rapid tooling, which can speed up the production process in some cases. For example, creating molds or fixtures for injection molding using SLA - printed patterns can save time compared to traditional manufacturing methods. Limitations: The cost can be a major drawback. The high - cost materials and relatively slow printing speed make it less cost - effective for large - scale production compared to some traditional mass - production methods like injection molding. Also, the build volume of most SLA printers is limited. Printing large numbers of large - sized parts may require multiple print runs, which can be time - consuming. And the post - processing steps, which are often necessary for SLA - printed parts, can also slow down the overall production rate when scaling up. So, while SLA can be used for large - scale production in some niche or high - value applications, it may not be the best choice for all high - volume production scenarios.