What is Aluminium Rapid Prototyping?

Aluminium rapid prototyping refers to the fast - paced process of creating a preliminary model or sample of a product using aluminium materials. This technique uses advanced manufacturing technologies such as 3D printing, CNC machining, and injection molding. It enables the quick production of aluminium prototypes that accurately represent the final product in terms of shape, structure, and to some extent, functionality.

In modern manufacturing, aluminium rapid prototyping plays a crucial role. For example, in the automotive industry, before mass - producing new car parts, aluminium rapid prototyping allows manufacturers to test the design's aerodynamics, durability, and fit. A car company can use this technology to quickly create a prototype of a new engine cover. By using aluminium, which is lightweight yet strong, they can evaluate how the part will perform in real - world conditions without investing a large amount of time and resources into full - scale production first.

In the aerospace field, where precision and weight reduction are of utmost importance, aluminium rapid prototyping is indispensable. It allows for the creation of prototypes of aircraft components, such as wing sections or engine brackets. These prototypes can be rigorously tested for strength, heat resistance, and fatigue resistance. This ensures that the final parts used in actual aircraft meet the high - standards of safety and performance required in the aerospace industry.

The Process of Aluminium Rapid Prototyping

1. Design Phase

The design phase is the foundation of aluminium rapid prototyping. It all starts with a clear understanding of the product's requirements, functions, and end - use. Designers use advanced Computer - Aided Design (CAD) software to create a 3D model of the prototype. This digital model is highly detailed, including every curve, hole, and surface finish requirement. For example, if you are creating a prototype of an aluminium heat sink for electronics, the CAD model will precisely define the fins' shape, thickness, and spacing to ensure optimal heat dissipation.

The accuracy of the design is crucial as any error in this stage can lead to costly mistakes later in the prototyping process. It is like building a house; a wrong blueprint will result in a flawed structure. In the context of aluminium rapid prototyping, a minor design flaw can cause issues such as improper fitment, reduced functionality, or even structural failures when the prototype is tested.

2. Material Selection

Aluminium is an ideal material for rapid prototyping due to its remarkable properties. It has a high strength - to - weight ratio, which means it can withstand significant stress while being relatively lightweight. For instance, in the aerospace industry, where every gram of weight matters, aluminium prototypes are used to develop components that need to be strong yet light.

Aluminium also has excellent thermal and electrical conductivity. In electronic device prototypes, this property is vital. For example, in the development of a new smartphone, an aluminium prototype of the internal heat - dissipation module can effectively transfer heat away from the high - power chips, ensuring the device's stable operation. Additionally, its corrosion - resistance makes it suitable for prototypes that will be exposed to various environmental conditions, such as outdoor equipment or marine applications.

3. Prototyping Techniques

- 3D Printing: This technique, also known as additive manufacturing, builds the aluminium prototype layer by layer. One of its significant advantages is its ability to create highly complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. For example, lattice - structured parts can be 3D printed, which are not only lightweight but also provide high strength. However, 3D printing of aluminium can be relatively slow, and the surface finish may not be as smooth as that of parts made by other methods. Also, the cost of 3D printers and aluminium powder materials can be high.

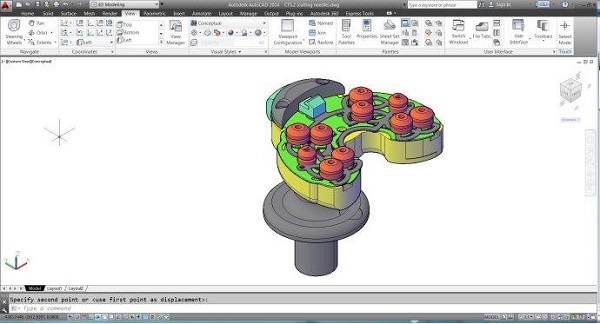

- CNC Machining: Computer - Numerical - Control (CNC) machining is a subtractive manufacturing process. It starts with a solid block of aluminium and uses precision - controlled cutting tools to remove material and shape the prototype. CNC machining offers high precision, with tolerances as low as ±0.001 inches in some cases. It can produce parts with excellent surface finishes. But, it may be time - consuming for complex shapes as a lot of material needs to be removed, and it may not be the most cost - effective for small - batch or highly complex designs.

- Casting: Casting involves pouring molten aluminium into a mold cavity. This method is suitable for creating prototypes with complex outer shapes. It can be relatively fast for large - volume production of the same prototype. However, the internal structure of cast parts may have porosity issues, and the dimensional accuracy may not be as high as that of CNC - machined parts.

The following table summarizes the comparison of these techniques:

| Prototyping Technique | Advantages | Disadvantages |

| 3D Printing | Can create complex geometries | Slow, high - cost, rough surface finish |

| CNC Machining | High precision, good surface finish | Time - consuming for complex shapes, high cost for small - batches |

| Casting | Fast for large - volume production, suitable for complex outer shapes | Porosity issues, lower dimensional accuracy |

Applications of Aluminium Rapid Prototyping

1. Aerospace Industry

In the aerospace industry, every component must meet the highest standards of performance and reliability. Aluminium rapid prototyping is widely used to create aircraft parts such as wing components, engine brackets, and landing gear parts. For example, in the development of a new aircraft model, a prototype of a wing spar can be quickly fabricated using aluminium rapid prototyping. This allows engineers to test the structural integrity, fatigue resistance, and aerodynamic performance of the part. Since aluminium is lightweight, it helps in reducing the overall weight of the aircraft. A lighter aircraft consumes less fuel, has a longer range, and can carry more payload. According to industry data, a 10% reduction in aircraft weight can lead to a 6 - 8% reduction in fuel consumption.

2. Automotive Industry

In the automotive sector, aluminium rapid prototyping plays a vital role in the development of new vehicles. It is used to produce engine components like engine blocks, cylinder heads, and intake manifolds. For instance, an aluminium engine block prototype can be made to test its heat dissipation capabilities, mechanical strength under high - stress conditions, and compatibility with other engine parts. Aluminium engine blocks are around 30 - 40% lighter than their cast - iron counterparts. This weight reduction not only improves fuel efficiency but also enhances the vehicle's handling and acceleration. Additionally, aluminium is used to create prototypes of wheels. Aluminium alloy wheels are not only lighter but also offer better heat dissipation during braking, improving the safety and performance of the vehicle.

3. Consumer Electronics

The consumer electronics industry benefits greatly from aluminium rapid prototyping. Aluminium is used to create prototypes of smartphone cases, laptop bodies, and tablet frames. Aluminium provides an elegant and durable finish to these devices. For example, a prototype of a new smartphone case made of aluminium can be tested for its impact resistance, scratch resistance, and radio - frequency interference shielding capabilities. In terms of heat dissipation, aluminium is an excellent choice. Laptop manufacturers often use aluminium prototypes to design effective heat sinks. Aluminium heat sinks can quickly transfer heat away from the CPU and GPU, ensuring that the device operates at a stable temperature even during intense usage, such as gaming or video editing.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in aluminium rapid prototyping. We have successfully applied this technology in various projects, from small - scale consumer product prototypes to large - scale industrial component development.

Aluminium rapid prototyping has significantly enhanced our business capabilities. It allows us to quickly turn our clients' ideas into tangible samples, reducing the time - to - market for new products. For example, when a client has a new design for an aluminium - based electronic enclosure, we can use rapid prototyping to create a sample within a short period for testing and validation.

We also leverage different prototyping techniques such as 3D printing and CNC machining according to the project requirements. This enables us to provide high - quality, customized aluminium prototypes that meet the specific needs of our clients, whether it's for design evaluation, functionality testing, or pre - production trials.

FAQ

1. What are the common problems in aluminium rapid prototyping?

Common problems in aluminium rapid prototyping include surface roughness in 3D - printed parts, which can be caused by the layer - by - layer building process. In CNC machining, issues like tool wear can affect the surface finish and dimensional accuracy. Casting may result in porosity within the prototype. To solve these problems, for 3D - printed parts, post - processing techniques such as sandblasting or polishing can improve the surface quality. In CNC machining, using high - quality cutting tools and proper tool - path planning can reduce tool wear and maintain accuracy. For casting, implementing proper degassing methods can minimize porosity.

2. How to choose the right aluminium alloy for rapid prototyping?

When choosing an aluminium alloy for rapid prototyping, consider the application. For aerospace applications where high strength and low weight are crucial, alloys like 7075 are suitable. It has high strength - to - weight ratio and good fatigue resistance. In automotive applications, 6061 alloy is often used. It offers a good balance of strength, corrosion resistance, and machinability. If the prototype needs to resist corrosion in a marine or chemical environment, 5052 alloy is a great choice due to its excellent corrosion - resistance properties.

3. Can aluminium rapid prototyping be used for mass production?

Aluminium rapid prototyping can be used for small - to - medium - scale mass production in some cases. Its advantage lies in the ability to quickly produce parts with complex geometries without the need for expensive tooling in the initial stages. However, for large - scale mass production, traditional manufacturing methods like die - casting or stamping may be more cost - effective. Die - casting can produce large volumes of parts at a lower cost per unit once the initial die - making investment is made. In contrast, 3D - printed aluminium parts for mass production may have high material and production costs. CNC - machined parts can be time - consuming and costly for high - volume production due to the subtractive nature of the process.