Full-color 3D printing is a transformative technology that allows for the creation of three-dimensional objects with a wide spectrum of colors directly from digital files. Unlike traditional single-color 3D printing, this technique enables the production of vivid, detailed, and realistic prints, opening up new possibilities across industries like manufacturing, healthcare, art, and more. It offers improved design flexibility, faster prototyping, and reduces the need for post-processing, making it a game changer in various sectors.

Introduction to Full-Color 3D Printing

Full-color 3D printing is a method of additive manufacturing that incorporates multiple colors in the printing process, producing objects with intricate details and realistic appearances directly from digital files. It allows designers and creators to produce complex, multi-colored prototypes or end-use products without the need for additional coloring or painting. This technology leverages advanced printers capable of handling various materials simultaneously, resulting in highly customizable and visually stunning outputs.

Definition and Principles

Full-color 3D printing refers to the process where objects are created layer by layer, utilizing materials in a range of colors. This method differs from traditional monochrome 3D printing, which typically uses a single material color. The process is additive, where each layer of material is deposited on top of the previous one until the object is complete. The core principle behind full-color 3D printing is the ability to mix and match various color materials within the same print, often in highly detailed and precise ways.

Advantages Over Monochrome Printing

Realistic Representation

One of the most significant advantages of full-color 3D printing is its ability to produce highly realistic and detailed objects. Unlike monochrome printing, which often requires post-processing such as painting or applying colors after printing, full-color printing integrates the colors directly during the manufacturing process. This allows for a more accurate representation of the final product.

Design Flexibility

Full-color 3D printing offers unparalleled design freedom. Designers can incorporate gradients, intricate patterns, and multiple colors into their models without the limitations of traditional methods. This flexibility enhances creativity and makes the design process more dynamic, especially in industries that require high attention to detail.

Reduced Post-Processing

In traditional 3D printing, objects often require additional post-processing, such as painting or applying color. With full-color printing, much of this extra work is eliminated, saving time and labor costs. The final product is ready for use or display immediately after printing.

Prototyping Efficiency

Full-color 3D printing significantly speeds up prototyping by allowing companies to produce realistic, colorful models quickly. These prototypes closely resemble the final product in both color and appearance, providing businesses with faster feedback and the ability to refine their designs before mass production.

Enhanced Marketing

In marketing and promotional efforts, colorful 3D printed models can provide a striking visual representation of products. Companies can use these vibrant models in their marketing materials, exhibitions, and client presentations, making a strong impression with realistic, eye-catching visuals.

Applications of Full-Color 3D Printing

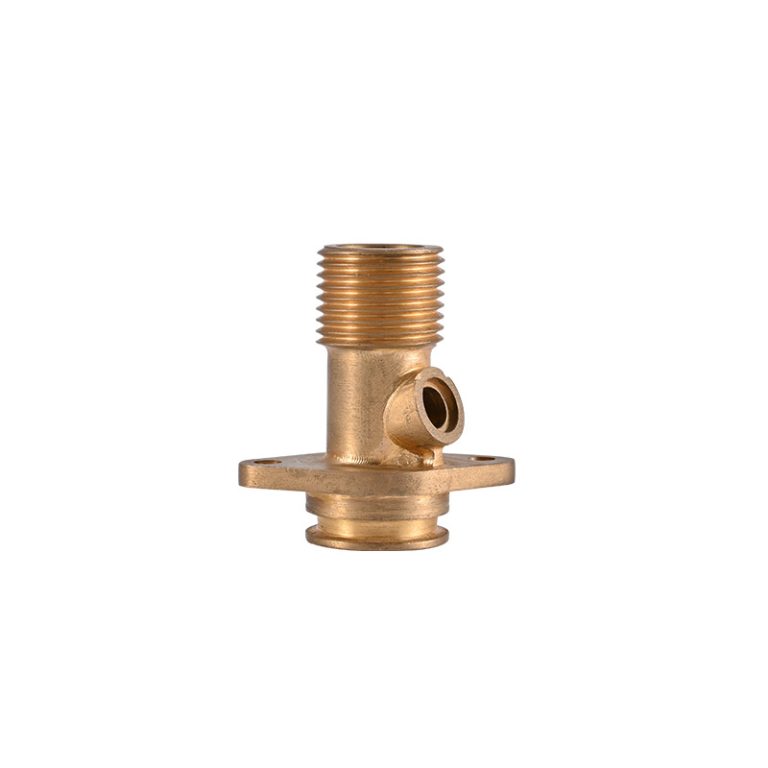

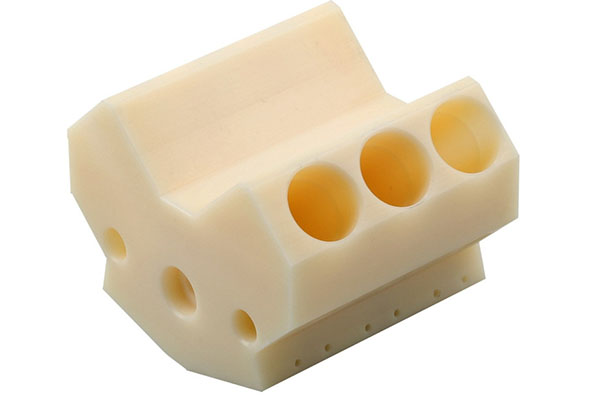

Industrial Design and Prototyping

Full-color 3D printing has become an invaluable tool for industrial designers in sectors such as automotive, consumer electronics, and home appliances. By using full-color prototypes, companies can evaluate both the functionality and aesthetic aspects of their designs before manufacturing. This capability is particularly useful when aesthetics play a vital role in consumer appeal, allowing companies to assess the look and feel of products early in the development process.

Medical and Dental Uses

In the medical field, full-color 3D printing is transforming how anatomical models are created for surgical planning, patient education, and training. Surgeons can now print highly detailed, accurate models of patient anatomy, allowing for better preoperative planning and more informed decision-making. In dentistry, full-color 3D printing is used to produce realistic orthodontic models, prostheses, and even custom surgical guides, improving treatment outcomes and patient satisfaction.

Art and Creative Expression

Artists are increasingly turning to full-color 3D printing to create sculptures, installations, and other creative works that were previously difficult or impossible to achieve. The ability to work in multiple colors at once allows for the creation of more dynamic and visually complex pieces, expanding the possibilities for artistic expression.

Technical Aspects

Color Layering Process

The color layering process in full-color 3D printing involves precisely applying layers of different colored materials to build up the object. There are two primary methods used:

- Multi-Material Jetting: In this process, print heads eject droplets of photopolymer resin, each with a different color, onto a build platform. The resin is cured with UV light after each layer is deposited. This method allows for precise color blending and vibrant, high-resolution prints.

- Binder Jetting: In this method, a powdered material is used as the base, and a liquid binder is applied in layers, along with colorants, to fuse the powder together. The result is a full-color print that can achieve intricate designs and vibrant colors.

Material Compatibility and Selection

The materials used in full-color 3D printing vary depending on the printing process. Commonly used materials include:

- Photopolymer Resins: Ideal for high-detail prints with smooth surfaces. These are typically used in multi-material jetting systems.

- Composite Resins: Often used for added strength and durability in prints that require more robust materials.

- Powder-Based Materials: Suitable for use with binder jetting, offering strength and resilience for more durable outputs.

Choosing the right material is critical for achieving the desired color and functional properties in the final product.

Software and Hardware Requirements

Full-color 3D printing requires advanced software and hardware. The software needs to handle complex color models and generate the necessary toolpaths for the printer. Popular software options include Voxel8's Digital Composite Manufacturing (DCM) Engine and Stratasys's GrabCAD Print. On the hardware side, printers like the Stratasys J750 and MiiCraft are specifically designed for full-color printing, offering precise control over multiple materials and colors.

Challenges and Limitations

Despite its advantages, full-color 3D printing faces several challenges:

- Cost: Full-color 3D printers and the necessary materials can be expensive, limiting access for small businesses or individual users.

- Complexity: The process is more complex than traditional 3D printing, requiring skilled operators and specialized maintenance.

- Color Fidelity: Achieving consistent color across different materials and print jobs can be challenging. Variations in material properties, environmental conditions, and printer calibration can affect the final color output.

Cost and Accessibility

Full-color 3D printing is still relatively costly, with printers and materials priced higher than standard 3D printing equipment. This makes it less accessible to small businesses and hobbyists at the moment. However, as the technology advances and becomes more widespread, it is expected that the costs will decrease, enabling broader adoption across industries.

Color Fidelity and Consistency

Achieving perfect color fidelity and consistency remains a significant challenge. Variations in the material, printer settings, and external factors can lead to subtle color differences. Manufacturers are actively working on improving printers and developing better materials and software to ensure more reliable and accurate color reproduction across different print jobs.

FAQs

What are the main advantages of full-color 3D printing over traditional methods?

- Realistic Representation: Creates visually accurate and lifelike models.

- Design Flexibility: Enables the use of multiple colors and intricate designs.

- Reduced Post-Processing: Eliminates the need for manual painting or additional coloring.

- Prototyping Efficiency: Accelerates product development with colorful, accurate prototypes.

- Enhanced Marketing: Provides striking visuals for promotional purposes.

What industries benefit most from full-color 3D printing?

Full-color 3D printing benefits various industries, including:

- Manufacturing: For realistic prototypes and product testing.

- Healthcare: For anatomical models, prosthetics, and surgical guides.

- Art: For intricate sculptures and mixed-media artworks.

- Education: For creating engaging and informative teaching aids.

How does full-color 3D printing work technically?

Full-color 3D printing is an additive manufacturing process that builds objects layer by layer. The process includes:

- Digital File Preparation: The design is created in 3D software.

- Material Dispensing: Specialized print heads apply colored materials onto the print bed.

- Layer Curing: Each layer is solidified using curing agents or UV light.

- Repeating the Process: Layers continue to be added until the object is complete.

This process allows for vibrant, multi-colored objects that can be used in diverse applications across industries.