Introduction to SLS Nylon Printing

Selective Laser Sintering (SLS) with Nylon is an advanced 3D printing technology that uses a laser to sinter (or fuse) nylon powder into solid, functional parts. Unlike other 3D printing methods, such as Fused Deposition Modeling (FDM) or Stereolithography (SLA), SLS uses a powder-based process that results in highly durable and complex geometries without the need for support structures. This makes it an attractive option for industries requiring strong, precise, and intricate parts, such as automotive, aerospace, medical, and consumer goods.

This article explores the principles behind SLS Nylon printing, its advantages, how it works, and its applications across various industries.

Definition and Principles

What is SLS Nylon Printing?

SLS Nylon Printing is a 3D printing method that uses a laser to selectively sinter nylon powder particles. The term "sintering" refers to the process of fusing these particles together without fully melting them, resulting in solid and durable structures. Unlike traditional manufacturing methods, where parts are cut or molded, SLS builds up parts layer by layer, which allows for greater design flexibility.

Principles of SLS Technology

The core of SLS technology involves the following sequential steps:

- Layer Preparation: A thin layer of nylon powder is evenly spread across the build platform. A roller or a similar device ensures a uniform powder layer.

- Laser Sintering: A high-powered laser (usually a CO2 laser) scans the powder bed and selectively heats the areas that correspond to the part's cross-section. The laser's heat causes the nylon particles to fuse together.

- Platform Lowering: After one layer is sintered, the build platform lowers slightly, and a new layer of powder is applied.

- Repetition: Steps 1-3 repeat until the part is fully built. Each layer fuses with the layer below it, resulting in a complete, solid part once the process finishes.

This process allows for the creation of parts with complex geometries and internal structures that are not possible with traditional manufacturing techniques.

Advantages Over Other 3D Printing Technologies

High Durability and Strength

One of the major benefits of SLS Nylon printing is the high mechanical strength of the resulting parts. Nylon has excellent properties, including tensile strength, impact resistance, and flexibility, making it ideal for functional prototypes and end-use parts that require durability and performance.

Complex Geometrical Capabilities

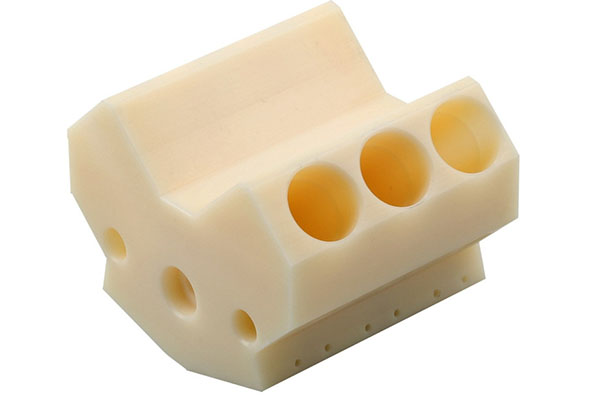

SLS printing offers unmatched design freedom. The absence of support structures—unlike other methods such as FDM (Fused Deposition Modeling)—enables the creation of intricate, complex geometries. These geometries can include hollow parts, lattice structures, or parts with interlocking features that are otherwise difficult or impossible to achieve with traditional manufacturing.

Direct Production of Moving Parts

SLS is capable of producing moving parts directly in the same print run. This reduces or eliminates the need for post-processing or assembly. This capability is especially useful for parts like gears, hinges, or other components that require mechanical movement.

Minimal Post-Processing

Compared to other technologies like FDM, parts produced via SLS generally require minimal post-processing. Since the parts are built from powder, the excess powder can be easily removed, and parts often need only light sanding or polishing before they are ready for use.

How SLS Nylon Printing Works

The Sintering Process

The sintering process in SLS Nylon printing involves a series of steps:

- Powder Bed Preparation: A thin layer of nylon powder is spread evenly across the build platform.

- Laser Scanning: The laser scans the cross-sectional layer of the part, selectively heating and sintering the nylon particles together at precise locations.

- Bonding: The laser's heat softens the nylon particles, causing them to bond to each other, forming a solid layer of material.

- Cooling and Solidification: The newly sintered layer cools and solidifies, ensuring the layer is stable before the next layer is applied.

- Repeat: The platform lowers by a small increment, and a fresh layer of powder is spread across the platform. The process repeats until the part is fully formed.

Material Properties of Nylon

Nylon is a versatile thermoplastic known for its excellent mechanical properties, including:

- High Tensile Strength: Nylon is strong, making it ideal for load-bearing parts.

- Impact Resistance: It is highly resistant to wear and tear, which is essential in harsh or industrial environments.

- Flexibility: It can bend without breaking, which is important for parts that need some degree of flexibility.

- Resistance to Chemicals: Nylon resists many types of chemicals, making it ideal for use in challenging environments.

These properties make it an ideal material for creating strong, functional parts via the SLS process.

Laser Technology Involved

The laser used in SLS Nylon printing is typically a CO2 laser with a power output between 50 and 100 watts. This laser is highly precise, allowing for the accurate sintering of nylon particles. The precision of the laser ensures the creation of parts with high detail and fine features.

Applications of SLS Nylon Printing

Industrial Prototyping

SLS Nylon printing is widely used for industrial prototyping because it allows for the creation of functional parts quickly and cost-effectively. Engineers and designers can use it to test designs, perform fit checks, and refine prototypes before moving to full-scale production.

Manufacturing of End-Use Parts

SLS Nylon printing isn't limited to prototypes; it can also be used for the production of end-use parts. Industries such as aerospace, automotive, and medical manufacturing rely on SLS to produce parts with high strength and precision. These can include components such as brackets, housings, gears, or even custom medical implants.

Customization and Complex Designs

SLS Nylon printing enables the creation of customized parts for specific needs. It is also ideal for producing complex designs that are tailored to meet precise requirements. This includes specialized tools, jigs, fixtures, and custom-fit parts that can't be easily manufactured through conventional means.

Comparison with Other 3D Printing Methods

FDM (Fused Deposition Modeling)

Advantages of SLS over FDM:

- No Support Structures: SLS does not require support structures, which are often necessary in FDM printing.

- Smoother Surface Finish: SLS parts typically have a smoother surface finish compared to FDM parts.

- Higher Mechanical Strength: SLS nylon parts tend to be stronger and more durable than FDM printed parts.

Disadvantages of SLS compared to FDM:

- Cost: SLS printers and materials are typically more expensive than FDM systems.

- Build Speed: FDM printing can be faster than SLS, especially for larger parts.

SLA (Stereolithography)

Advantages of SLS over SLA:

- Material Versatility: SLS can use a variety of materials (e.g., nylon, glass-filled nylon), while SLA primarily uses photopolymer resins.

- Durability: Nylon parts from SLS are more durable and impact-resistant than parts made from SLA resins.

- No Resin Handling: SLS doesn't require the handling of liquid resins, which can be messy and hazardous.

Disadvantages of SLS compared to SLA:

- Resolution: SLA generally provides higher resolution and finer details than SLS.

- Post-Processing: SLA parts may require less post-processing than SLS parts, which often need powder removal and sanding.

DLP (Digital Light Processing)

Advantages of SLS over DLP:

- Functionality: SLS can produce functional parts directly from the printer, while DLP parts often require additional curing and post-processing.

- Material Strength: SLS parts made from nylon are typically stronger and more durable than parts made with DLP resins.

- Material Range: SLS supports a wider range of materials, including engineering-grade plastics.

Disadvantages of SLS compared to DLP:

- Resolution: DLP provides higher resolution for fine details compared to SLS.

- Speed: DLP can be faster for small parts, as it cures entire layers in one pass.

Conclusion

SLS Nylon printing is an advanced and versatile 3D printing technology that offers numerous benefits over other methods. Its ability to produce high-strength, durable, and complex parts without the need for support structures makes it a preferred choice for industries that require functional prototypes or end-use parts. While it comes with a higher initial cost and potentially slower build times, the advantages in terms of design freedom, material properties, and part functionality make SLS Nylon printing a valuable tool for modern manufacturing. Whether it's for industrial prototyping, end-use parts, or custom designs, SLS Nylon printing continues to push the boundaries of what is possible in additive manufacturing.