Introduction to Short Run CNC Machining

Definition and Overview

Short run CNC machining involves producing a limited number of parts or components using computer numerical control (CNC) machines. This method is ideal for creating prototypes, custom parts, and components that require high precision. It allows for quick machine setup and minimal downtime between tasks, resulting in improved efficiency. CNC machines also offer high accuracy and repeatability, essential for producing complex parts that meet strict specifications. Short run CNC machining is especially valuable for businesses that need to adapt quickly to market changes or customer demands.

Advantages Over Traditional Machining

Short run CNC machining provides numerous advantages over traditional methods. One of the most notable is its flexibility: CNC machines can be easily reprogrammed to handle different tasks, reducing setup time and downtime. In contrast, traditional machining often requires more extensive setup and tooling changes, which can be time-consuming and less efficient. CNC machines are also more precise, providing a high level of accuracy and consistency, which is critical in industries requiring tight tolerances.

Key Benefits of Short Run CNC Machining

Short run CNC machining offers several important benefits, particularly for industries that rely on speed, precision, and cost efficiency:

Quick Setup and Changeover

The ability to rapidly set up and change between different production tasks is one of the most significant benefits of short run CNC machining. Machine operators can change tools, adjust settings, or switch between tasks in a matter of minutes, minimizing idle time. This fast transition ensures that production can continue with minimal disruption, improving overall efficiency and productivity.

High Precision and Repeatability

CNC machines operate with incredible precision, following exact instructions from digital designs. This ensures that parts are produced with consistent quality, meeting the specified tolerances every time. Even with complex geometries, CNC technology guarantees repeatability, reducing defects and minimizing the need for rework or scrap.

Cost-Effectiveness for Small Batch Production

While the initial investment in CNC equipment may be higher than traditional machinery, short run CNC machining offers significant cost savings for small batch production. The reduction in setup times, labor costs, and material waste makes it an economical choice for producing low quantities of custom or specialized parts. The ability to produce parts quickly also reduces the time to market, which can be a key factor in gaining a competitive edge.

Applications of Short Run CNC Machining

Prototyping

Short run CNC machining is commonly used for prototyping. Engineers and designers often require physical prototypes to test new designs and validate concepts before proceeding with full-scale production. CNC machining allows for the rapid production of high-precision prototypes, which speeds up the iteration process and facilitates faster decision-making.

Custom Orders

Many industries, including automotive, aerospace, and medical, require custom components that are tailored to specific needs. Short run CNC machining is ideal for producing these custom parts, as it can quickly adjust to new designs and handle a variety of materials. Whether creating one-off parts or small quantities, CNC machining offers the flexibility to meet unique customer specifications.

Complex Component Manufacturing

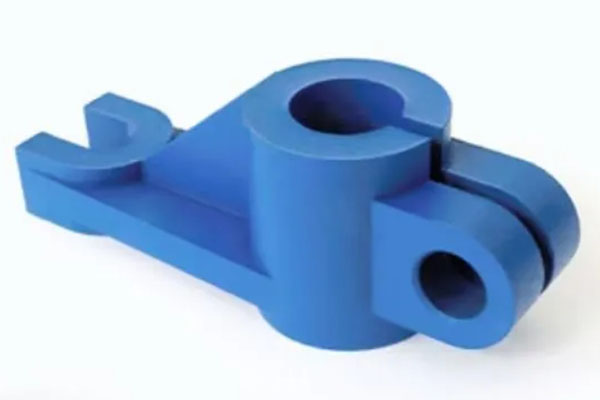

Short run CNC machining excels at manufacturing complex components that require high precision and intricate design details. For industries like aerospace and medical devices, where component failure can have severe consequences, CNC machining provides the accuracy and repeatability necessary to produce critical parts with tight tolerances and complex geometries.

The Role of Short Run CNC Machining in Modern Manufacturing

As industries evolve and product lifecycles shorten, short run CNC machining has become an integral part of modern manufacturing strategies. This method supports rapid innovation, allowing companies to quickly adapt to changing customer needs and market trends. By reducing setup times, increasing precision, and offering cost-effective solutions for low-volume production, short run CNC machining helps businesses stay competitive and responsive to market demands.

Future Trends and Technological Advancements

Integration with Additive Manufacturing

One of the emerging trends is the integration of CNC machining with additive manufacturing (3D printing). Combining both technologies provides a hybrid solution that offers greater flexibility in part production. Additive manufacturing can quickly create complex shapes, while CNC machining can refine and finish these parts to meet exact specifications, enhancing both speed and quality.

Advanced Software and Automation

Advancements in software and automation will continue to shape the future of short run CNC machining. Intelligent software that incorporates machine learning can optimize machining processes, predict tool wear, and reduce errors, leading to higher efficiency. Further developments in automation will allow for more autonomous operations, reducing the need for manual intervention and increasing throughput.

Sustainable Manufacturing Practices

Sustainability is becoming increasingly important in manufacturing, and short run CNC machining is no exception. Future advancements are likely to focus on reducing material waste, energy consumption, and emissions associated with machining operations. Manufacturers may also embrace recycling and eco-friendly materials, contributing to a more sustainable production process while maintaining high-quality standards.

Conclusion

Short run CNC machining plays a crucial role in improving productivity and efficiency across a wide range of industries. Its ability to quickly adapt to new tasks, provide high precision and repeatability, and offer cost-effective solutions for small batch production makes it indispensable for modern manufacturing. As technology continues to evolve, CNC machining will remain at the forefront of innovation, enabling manufacturers to meet the demands of a rapidly changing marketplace.

FAQs

What is short run CNC machining?

Short run CNC machining refers to the production of a limited number of parts or components using computer numerical control (CNC) machines. It is particularly suited for prototypes, custom orders, and parts that require high precision, enabling quick setup and changeover with minimal downtime.

What are the main advantages of short run CNC machining over traditional machining?

Short run CNC machining offers faster setup, higher precision, repeatability, and cost-effectiveness for small batch production. Unlike traditional machining, CNC machines can be easily reprogrammed to switch tasks quickly, minimizing downtime and ensuring consistent part quality.

What are some common applications of short run CNC machining?

Short run CNC machining is commonly used for prototyping, custom orders, and manufacturing complex components. Industries such as automotive, aerospace, and medical benefit from its flexibility and precision in producing specialized parts with tight tolerances and intricate designs.