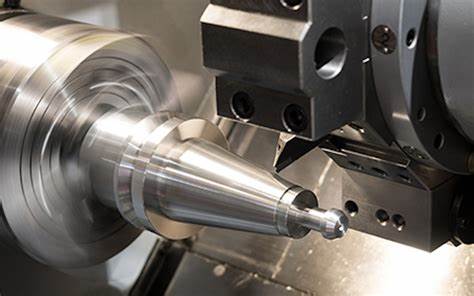

If you’ve ever struggled with getting clean cuts or avoiding burrs when turning copper, you’re not alone. Copper’s unique properties—like its softness and tendency to stick to tools—make it trickier to machine than harder metals like steel. But with the right knowledge of materials, tools, parameters, and problem-solving tips, you can master copper turning. This guide takes you from the basics of copper types to advanced finishing techniques, so you’ll walk away with actionable steps to improve your work.

1. Understanding Copper Materials: Which Type Should You Use?

Before you start turning, it’s critical to pick the right copper alloy—each has properties that directly impact machining. Let’s break down the most common types and how they perform in turning.

Key Copper Material Types and Their Properties

| Material Type | Key Properties | Best For | Machining Notes |

| Pure Copper | High thermal conductivity, soft & gummy | Electrical components, busbars | Prone to built-up edge; needs sharp tools |

| Oxygen-Free Copper | Low oxygen content, high ductility | Waveguides, precision electrical parts | Less prone to oxidation; requires coolant |

| Beryllium Copper | Harder than pure copper, good strength | High-stress parts (e.g., valves) | Needs higher cutting speeds; less galling |

| Brass (Cu-Zn) | Harder than pure copper, machinable | Plumbing fittings, decorative parts | Easier to turn; better chip control |

| Bronze (Cu-Sn) | Strong, corrosion-resistant | Bearings, marine parts | Can be brittle; adjust feed rates carefully |

Real-World Example: Last year, I worked with a client who was turning pure copper for electrical busbars. They kept getting a sticky built-up edge on their tools, which ruined the surface finish. We switched to oxygen-free copper and added a high-pressure coolant system—immediately, the built-up edge disappeared, and their production speed increased by 20%.

The key takeaway here is that High Thermal Conductivity and High Ductility (common in pure copper) make it prone to heat buildup and tool adhesion. Harder alloys like brass or beryllium copper are more forgiving but still need specific tooling.

2. Choosing the Right Cutting Tools for Copper Turning

Using the wrong tool is the #1 mistake I see in copper turning. Unlike steel, copper doesn’t harden when cut—so you need tools that stay sharp, reduce friction, and avoid galling (material sticking to the tool).

Must-Have Tool Features for Copper

- Sharp Cutting Edge: Dull edges cause tearing and built-up edge. I sharpen my tools every 2–3 hours when turning pure copper.

- Polished Rake Face: A smooth rake face (Ra < 0.8 μm) reduces friction, which stops copper from sticking. I polish mine with a diamond stone for best results.

- Positive Rake Angle: A 10–15° positive rake angle helps the tool “slice” through copper instead of pushing it. Negative angles can cause more heat.

- Large Clearance Angle: 8–12° clearance angles prevent the tool’s flank from rubbing against the workpiece, which reduces wear and surface roughness.

Tool Material Comparison

| Tool Material | Best For | Speed Range (SFM) | Pros | Cons |

| High-Speed Steel (HSS) | Low-volume jobs, manual lathes | 100–300 | Cheap, easy to sharpen | Wears fast at high speeds |

| Uncoated Carbide | Medium-volume, CNC lathes | 300–600 | Longer tool life than HSS | Needs sharp edges; can chip if dull |

| PCD (Polycrystalline Diamond) Inserts | High-volume, precision parts | 600–1200 | Ultra-sharp, minimal wear | Expensive; not for brass/bronze (abrasive) |

Pro Tip: For brass or bronze, avoid PCD inserts—these alloys have small abrasive particles that will wear down diamond quickly. Stick to uncoated carbide instead. I once made this mistake and went through $200 worth of PCD inserts in a day before switching to carbide!

3. Machining Parameters & Techniques for Flawless Copper Turning

Even the best tools won’t work if your parameters are off. Copper’s softness means you need to balance speed, feed rate, and coolant to avoid heat buildup and poor finishes.

Step-by-Step Parameter Setup

- Cutting Speed: Start with High Cutting Speeds—slower speeds let copper stick to the tool. For HSS, aim for 100–300 SFM; for carbide, 300–600 SFM; and for PCD, 600–1200 SFM.

Example: When turning brass plumbing fittings with carbide, I run at 450 SFM—this gives clean chips and a smooth finish.

- Feed Rate: Use Moderate to High Feed Rates (0.002–0.005 ipr) to break chips into small pieces. Slow feeds can cause long, stringy chips that are hard to evacuate.

- Depth of Cut: For roughing, use 0.050–0.100” depth of cut; for finishing, 0.005–0.010”. Too deep a finish cut can deform the workpiece (thanks to copper’s High Ductility).

- Coolant: Copious Coolant is non-negotiable. Use a water-soluble coolant with good lubricity (3–5% concentration). I’ve found that flood cooling works better than mist for copper—it keeps the tool and workpiece cooler.

Critical Techniques to Avoid Mistakes

- Climb Turning: Always use climb turning (tool moves with the workpiece’s rotation) for copper. It reduces tool pressure and gives a smoother surface. I switched to climb turning for a client’s heat exchanger tubes and their surface roughness dropped from Ra 6.3 to Ra 1.6.

- Avoid Dwell: Never let the tool sit in one spot—this causes heat buildup and can leave a indentation. If you need to pause, move the tool away from the workpiece.

- Effective Chip Evacuation: Use a chip breaker geometry (like a C-type breaker) to break chips into small, manageable pieces. Long chips can wrap around the tool or workpiece, causing damage.

4. Solving Common Copper Turning Challenges

Even with the right setup, you’ll run into issues. Here’s how to fix the most common problems I’ve seen in 10+ years of machining copper.

Troubleshooting Guide for Copper Turning

| Challenge | Cause | Solution |

| Burr Formation | Dull tool, low feed rate | Sharpen tool; increase feed rate by 0.001 ipr |

| Material Adhesion | Polished rake face missing, low coolant | Polish rake face; increase coolant flow |

| Surface Roughness | High cutting speed, dull tool | Reduce speed by 50 SFM; sharpen tool |

| Chip Control Issues | Wrong chip breaker, low feed rate | Switch to a more aggressive chip breaker; increase feed |

| Workpiece Deformation | Too much tool pressure, thin workpiece | Use a softer cutting tool; add a steady rest |

| Heat Buildup | Insufficient coolant, high depth of cut | Increase coolant; reduce depth of cut by 0.020” |

| Parting-off Difficulties | Dull parting tool, low coolant | Use a sharp PCD parting tool; direct coolant at the cut |

Case Study: A manufacturer was struggling with parting-off pure copper rods (1” diameter) for electrical components. They kept getting uneven cuts and broken tools. We found two issues: their parting tool was dull, and they weren’t using enough coolant. We replaced the tool with a sharp carbide parting insert and added a dedicated coolant nozzle for the parting tool. After that, their parting-off time dropped by 30%, and they had zero broken tools in a month.

5. Applications & Finishing Techniques for Copper Parts

Copper turning parts are used in everything from electronics to plumbing—but the finishing step is what makes them ready for use. Let’s cover the most common applications and how to finish them.

Common Copper Turning Applications

- Electrical Components: Pure or oxygen-free copper is used for connectors and busbars because of its High Thermal Conductivity. Finishing: Deburr and polish to ensure good electrical contact.

- Heat Exchanger Tubes: Brass or bronze tubes are preferred for their corrosion resistance. Finishing: Use a 320-grit sandpaper to smooth the inside of the tube for better heat transfer.

- Busbars: Thick pure copper pieces that carry electricity. Finishing: Deburr all edges to prevent arcing; a high-gloss polish is optional for aesthetics.

- Waveguides: Oxygen-free copper is used for its low signal loss. Finishing: Ultra-fine polishing (Ra < 0.2 μm) to reduce signal reflection.

- Plumbing Fittings: Brass is the go-to material for its machinability and corrosion resistance. Finishing: Deburr threads; a clear coat can prevent tarnishing.

Step-by-Step Finishing Process

- Deburring: Use a deburring tool or 120-grit sandpaper to remove sharp edges. For small parts, I use a vibratory tumbler with ceramic media—it’s fast and consistent.

- Polishing: Start with 240-grit sandpaper, then move to 400-grit, 600-grit, and finally a polishing compound (like rouge). For precision parts, use a buffing wheel at 1500 RPM.

- Corrosion Resistance: For outdoor or wet applications (like marine parts), apply a clear lacquer or plating (e.g., nickel). Brass fittings often get a chrome plate for extra durability.

Expert Insight: When finishing waveguides, even a small scratch can affect performance. I once had to rework a batch because a technician skipped the 600-grit step— the signal loss was 10% higher than specs. Always follow the grit sequence!

Yigu Technology’s Perspective on Copper Turning

At Yigu Technology, we’ve worked with countless clients on copper turning projects, from small electrical components to large heat exchanger tubes. What we’ve learned is that success in copper turning comes down to balancing material selection, tooling, and process control. Many manufacturers overlook the importance of coolant—using the right type and pressure can solve 50% of common issues like built-up edge and heat buildup. We also recommend investing in PCD inserts for high-volume precision jobs—while they cost more upfront, they save time and money in the long run by reducing tool changes and improving finish quality. Finally, don’t underestimate the value of training: even experienced machinists need to learn copper-specific techniques, like climb turning and proper deburring, to get the best results.

FAQ: Your Copper Turning Questions Answered

Q1: Can I use the same tools for brass and pure copper?

A: No—brass is harder and less sticky than pure copper. For brass, uncoated carbide works well; for pure copper, you’ll need a sharper tool (like PCD) or a polished HSS tool to avoid adhesion.

Q2: How do I prevent built-up edge when turning pure copper?

A: Use a sharp tool with a polished rake face, high cutting speeds (300+ SFM for carbide), and copious coolant. If you still have issues, try increasing the feed rate slightly—this helps break chips and reduces tool contact time.

Q3: What’s the best coolant for copper turning?

A: A water-soluble coolant with good lubricity (3–5% concentration) is ideal. Avoid oil-based coolants—they can leave a residue that’s hard to clean off, which is a problem for electrical parts.

Q4: Why is my copper workpiece deforming during turning?

A: Deformation is usually caused by too much tool pressure or a thin workpiece. Try reducing the depth of cut, using a softer cutting tool (like HSS instead of carbide), or adding a steady rest to support the workpiece.

Q5: How do I get a high surface finish on copper?

A: Use a sharp PCD insert (for CNC) or a polished HSS tool (for manual lathes), low depth of cut (0.005–0.010”), and high cutting speeds. Finish with a 600-grit sandpaper and polishing compound for a mirror finish.