If you’ve ever needed precision parts for aerospace, medical devices, or automotive projects, you’ve probably searched for CNC companies—but not all providers are created equal. In 2026, the global CNC market hits $108.63 billion and is projected to grow at 7.79% annually through 2030 , making it critical to know how these firms operate and how to pick the right one. Let’s break this down step by step.

What Exactly Do CNC Companies Do?

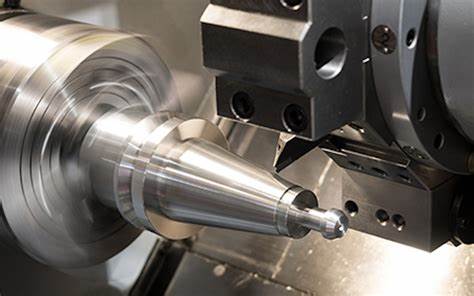

At their core, CNC companies use Computer Numerical Control (CNC) machines to transform raw materials into precise components. But top-tier firms offer far more than basic machining: they provide end-to-end solutions tailored to industries like aerospace, medical, and automotive .

For example, a leading CNC company recently produced 200 Inconel 718 fuel nozzles for a jet engine manufacturer—achieving zero defects in strict FAA audits . Another firm cut production time for a satellite component by 40% using AI-optimized toolpaths . These aren’t just "machine shops"—they’re manufacturing partners.

Key services from reputable CNC companies include:

- Precision machining (milling, turning, 5-axis work)

- Material expertise (titanium, aluminum, PEEK, composites)

- Surface treatments (anodizing, plating)

- Assembly and integration

- Design for Manufacturability (DFM) consulting

The 2026 CNC Market: Key Stats & Trends

To understand CNC companies, you first need context on the industry’s size and direction. Here are the critical numbers:

- Global CNC machine market size: $751.6 billion (2026)

- Chinese CNC market size: $229.1 billion (2026)

- Annual growth rate (2026-2030): 7.79%

- Top application: Automotive (driven by EV production)

3 Game-Changing Trends Shaping CNC Companies

- AI Integration: Smart software reduces tool wear by 25% and optimizes cycle times . Leading firms now use AI for real-time quality checks.

- Automation: Lines with 95% automation cut costs by 20-35% and speed up delivery.

- Sustainability: Top providers recycle 95% of metal waste and use renewable-powered machines —critical as brands prioritize eco-friendly supply chains.

How to Choose the Right CNC Company: A Practical Checklist

Selecting a CNC company is make-or-break for your project. Use this comparison framework to evaluate providers:

| Evaluation Category | Key Questions to Ask | Must-Have Standards |

|---|---|---|

| Technical Capability | What machines do they use? (5-axis? Swiss-style?)What tolerances can they achieve? | ±0.001mm accuracy for precision partsMulti-axis machines for complex geometries |

| Material Expertise | Have they worked with your material (e.g., titanium, PEEK)?Do they handle hard-to-machine metals? | Experience with industry-specific materialsProven process for reducing material waste |

| Quality Control | What certifications do they hold?How do they test finished parts? | ISO 9001/13485 (medical) / AS9100 (aerospace)SPC 管控 for key processes |

| Production Capacity | Can they handle prototypes (1-10 units) and mass production (10k+)?What’s their lead time? | Sample delivery: 3-7 daysMass production 20% faster than industry average |

| Transparency | Can you track production in real time?Do they share process updates? | Online production visualization systemRegular progress reports |

Real-World Example: The Cost of Choosing Wrong

A medical device startup once picked a CNC company based solely on low prices. The firm lacked ISO 13485 certification and cut corners on material testing. Result: 80% of spinal implants failed biocompatibility tests, costing the startup $200k in rework and a 6-month launch delay. A certified provider would have caught this early.

Top CNC Company Specializations by Industry

Not all CNC companies excel in every sector. Here’s how to match providers to your needs:

Aerospace & Defense

- Focus: Turbine blades, UAV frames, radar housings

- Critical Requirements: AS9100 certification, ±0.005mm accuracy for engine parts

- Case Study: A CNC firm supplied 5-axis machined engine blades to a defense contractor—reducing weight by 15% while maintaining strength .

Medical Devices

- Focus: Surgical robot arms, titanium implants

- Critical Requirements: ISO 13485, 0.002″ positional accuracy

- Win: A provider’s DFM advice cut a surgical tool’s production cost by 22% and boosted yield to 99.9% .

Automotive (EV)

- Focus: Battery trays, transmission gears

- Critical Requirements: High-volume production, lightweight material expertise

- Trend: Firms using 40k-rpm 主轴 machines to cut mold time by 60% .

Yigu Technology’s Perspective

The CNC industry is evolving from "machining services" to "solution partnerships." At Yigu Technology, we believe the best CNC companies don’t just follow blueprints—they co-create them. Clients now demand more than accuracy: they want AI-driven efficiency, sustainability, and flexibility to scale from prototype to production. We’re seeing a shift toward "vertical integration"—combining machining, surface treatment, and assembly—to shorten supply chains. For businesses, this means choosing providers that align with long-term goals, not just immediate costs. The future belongs to CNC companies that merge technical precision with collaborative problem-solving.

FAQ About CNC Companies

Q: How much does it cost to work with a CNC company?A: Costs vary by part complexity, material, and volume. Prototypes start at $50-$200, while mass production can drop to $5-$10 per unit. Always ask for a detailed quote with material and labor breakdowns.

Q: What’s the difference between 3-axis and 5-axis CNC companies?A: 3-axis machines move along X/Y/Z axes (good for simple parts). 5-axis machines add rotational axes—ideal for complex shapes like impellers. Choose 5-axis if your part has curved surfaces or requires multiple setups.

Q: How can I verify a CNC company’s quality claims?A: Ask for: 1) Certification copies (ISO/AS9100), 2) Recent customer testimonials, 3) First-article inspection reports, and 4) A tour of their quality lab (in-person or virtual).

Q: Do CNC companies offer design help?A: Top firms provide free DFM reviews to optimize your design for machining—this can reduce costs by 15-30% and avoid production delays. Always ask about this upfront.