1. Project start-up: do a good job in planning and management to lay the foundation for success

The success of any machining project is inseparable from careful project feasibility analysis and system management in the early stage. First, the project boundaries should be clarified through three-dimensional requirements clarification (technology, business, risk), such as drawing a product structure tree (BOM) to lock in key parameters, and an auto parts project avoided subsequent rework by clarifying the requirements of tolerance ±0.01mm and surface roughness Ra≤1.6μm.

Machining task decomposition It is recommended to use the WBS work decomposition method to break down complex projects into executable operation units. A new energy battery project is decomposed into five modules: "material procurement, rough processing, finishing, testing, and assembly", so that the responsibilities of each link are clear. The time schedule needs to build a three-level planning system, with a 10-15% buffer period reserved for milestone plans, and a "push-forward method" for monthly rolling plans to reverse the construction period, and weekly plans to clarify priorities, which can shorten the construction period by an average of 15-20%.

Resource demand planning and project team formation should match the project scale: small projects with a budget < 5 million yuan can be coordinated by the production supervisor; 5 million to 30 million medium-sized projects are suitable for matrix teams, giving project managers the right to schedule equipment; ≥ large projects of 30 million yuan require independent project-based teams. The value of resource planning is when a project uses a "resource calendar" to lock in five key devices in advance, increasing equipment utilization from 60% to 85%.

2. Technical tackling: scheme design determines the core quality of the project

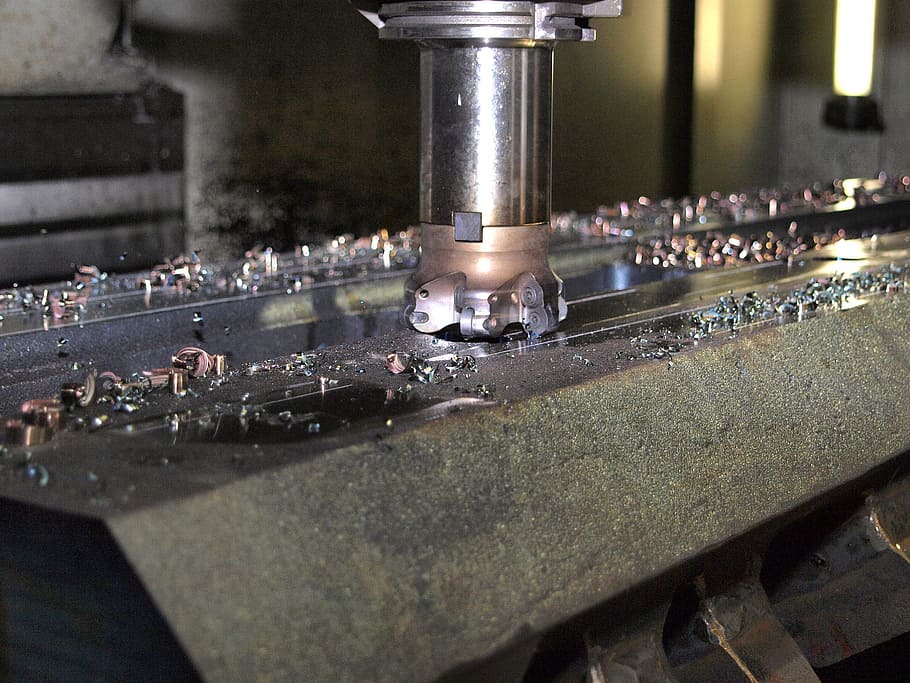

Process route planning is the core of the technical solution, and the optimal path needs to be selected based on the characteristics of the product. In the processing of aluminum alloy decorative strips for high-speed rail carriages, traditional CNC is prone to knife marks, and Zhikai CNC adopts "pulse power adaptive adjustment technology" to control the contour accuracy at ±0.003mm, and the surface roughness is stable at Ra≤0.7μm. The equipment selection and configuration should take into account both precision and efficiency, and the middle wire walking machine tool has obvious advantages in precision parts processing, its processing efficiency is 40% higher than that of traditional equipment, and the defect rate can be reduced from 3.2% to 0.8%.

The design and production of fixtures and the determination of tool schemes directly affect the machining stability. A mold factory once caused frequent wire breakage due to improper tool selection, and after replacing special alloy tools, the cost of consumables was reduced by 28%. In the face of technical difficulties, it is recommended to adopt parallel engineering thinking and carry out process review simultaneously in the design stage, and an auto parts project changed the serial process to parallel in this way, shortening the construction period by 30 days. Process parameter optimization relies on data accumulation, such as adjusting the cutting speed according to the hardness of the material, and optimizing the rotation speed from 1500r/min to 2200r/min during mold steel processing, which can improve efficiency by 30%.

3. Cost control: Careful budgeting to maximize profits

Material cost accounting should not only look at the purchase price, but also consider the utilization rate. When processing 80mm thick mold steel, a hardware factory in Zhejiang later adopted the "nesting processing" model, which increased the material utilization rate from 65% to 82%. The calculation of machining hours needs to be combined with the hourly rate of equipment (80-150 yuan/hour), and then superimposed on tool consumption statistics and equipment depreciation allocation (annual depreciation rate of about 15%) to obtain the true cost.

Quality cost control is the key to implicit money saving. After the introduction of Zhikai equipment in a mold factory in Changzhou, the scrap rate dropped from 12% to 0, saving more than 200,000 yuan per year alone. Efficiency solutions can start with equipment OEE, increasing equipment utilization from 55% to 89% through "three shifts" and "device sharing pool" models. Return on investment analysis shows that reasonable cost optimization can increase project ROI by an average of 18-25%, with the core being to balance upfront investment with long-term returns.

4. Quality and Schedule: Two-wheel drive ensures project delivery

The quality plan needs to clarify the whole process standards, including process inspection arrangements (such as sampling ratio of 5%), accuracy assurance measures (such as the first article three inspection system), and surface quality requirements. An aviation component project monitored the pass-through rate in real time through the "project cockpit" and found that the surface treatment yield was only 78%, and then adjusted the process in time, increasing it to 91% within 3 weeks. The treatment of non-conforming products should follow the principle of "48-hour time limit", and establish a traceability mechanism to avoid recurrence.

The core of schedule management is bottleneck process identification and resource allocation strategy. A motor project has increased the complete component assembly rate from 75% to 98% and reduced downtime by 60% through weekly planning control. In the face of the risk of delay, it is necessary to formulate delay response measures, such as backup suppliers and multi-modal transportation plans, and a medical device project was delivered as scheduled through charter transportation during the epidemic without compensation for breach of contract. The delivery guarantee plan should establish a progress reporting system, small projects should be reported weekly, and large projects should progress synchronously every day.

5. Achievement delivery and case reference: closed-loop management + experience reuse

The confirmation of the delivery list needs to be detailed to the packaging standards and technical data, including quality documents, test reports and other quality documents collation and technical data archiving. The customer acceptance process should strictly follow the agreement, and sample and test 23 key indicators to ensure that it meets the customer acceptance standards. An electronic project avoided subsequent disputes due to the clear acceptance process in advance, and the customer satisfaction rate reached 98%.

Project case studies provide valuable experience. Success stories show that projects with matrix management, parallel engineering, and smart devices have a 42% higher success rate than the industry average. Lessons from failure remind us that neglecting risk assessment management (e.g., single vendor dependency) and process risks (e.g., insufficient maturity of new technologies) can lead to project delays of more than 30%. The direction of continuous improvement should focus on customer feedback, and a high-speed rail supporting enterprise optimized the design of the decorative strip installation interface by collecting customer suggestions, and the subsequent orders increased by 25%.

6. Yigu Technology's views

The essence of the success of a machining project is a coordinated closed loop of planning, technology, cost, quality, and schedule. Enterprises need to get rid of the "heavy production over management" mentality and use digital tools (such as MES systems, project cockpits) to improve control accuracy, while paying attention to equipment upgrades and team empowerment. Under the trend of high-end manufacturing, only by integrating the principle of E-E-A-T into the whole project process, focusing on customer needs and taking data as the basis for decision-making, can we stand out in the fierce competition. It is recommended that small and medium-sized enterprises give priority to cost control and quality improvement, accumulate project management experience through small iterations, and gradually achieve large-scale and refined operations.

FAQ

- How can machining projects quickly identify bottleneck processes?

A: Through the real-time monitoring of the cycle time of each process through the MES system, combined with the equipment load factor data, the load rate exceeds 85% and the accumulation of work-in-progress between processes is a bottleneck, which can be broken through by increasing manpower, optimizing parameters or upgrading equipment.

- What is the reasonable proportion of quality costs in precision machining projects?

Answer: The industry benchmark is 8-12% of the total project cost, of which prevention costs (such as training and testing equipment) account for 3-5%, identification costs (such as inspection, testing) account for 2-4%, and failure costs (such as rework, scrapping) should be controlled within 2%.

- What happens when a project is delayed by more than 10%?

Answer: First, start delay response measures to assess whether they affect key nodes; secondly, it is compensated by compressing the construction period of non-critical paths and allocating resources (such as rental equipment); Finally, communicate with the customer to adjust the delivery plan to avoid compensation for breach of contract.

- How do you balance accuracy and cost when selecting equipment?

Answer: According to the precision requirements of the project, ordinary parts (tolerance ±0.02mm) can choose economical equipment, precision parts (tolerance ≤±0.005mm) are recommended to choose high-end equipment such as wire rolling, in the long run, high-precision equipment can reduce quality costs, ROI is better.