Introduction

Understanding CNC Subcontract Machining

CNC, short for Computer Numerical Control, subcontract machining is a manufacturing process where a company outsources the production of parts to a specialized CNC machining service provider. This involves using computer - controlled machine tools, such as mills, lathes, and routers.

The basic principle is simple yet highly effective. First, a 3D model of the part is created using Computer - Aided Design (CAD) software. Then, this design is translated into a set of instructions, called G - code, which the CNC machine can understand. The machine reads these instructions and precisely manipulates the cutting tools to remove material from a raw workpiece, gradually shaping it into the desired part. For Yigu Technology example, if you need a complex - shaped aluminum bracket for a piece of equipment, the CAD model will detail every curve and hole. The CNC machine will follow the G - code derived from this model, accurately drilling holes, milling slots, and turning the edges to create the perfect bracket.

The Significance in Service Industries

Service industries, which include sectors like healthcare, aerospace, and automotive, rely heavily on high - precision components. CNC subcontract machining plays a crucial role in these industries. In healthcare, for instance, surgical instruments and prosthetics require extreme precision to ensure patient safety and effectiveness. A slight deviation in the shape or size of a prosthetic hip joint can cause discomfort or even failure. In the aerospace industry, where components need to withstand high - stress environments, CNC - machined parts offer the reliability and precision necessary for flight safety. In automotive manufacturing, the demand for mass - produced, high - quality parts is met efficiently through CNC subcontract machining. It serves as the backbone for these service industries, enabling them to produce products that meet strict quality standards, and this is why understanding its benefits is so important.

Precision and Quality Assurance

Unparalleled Precision

CNC subcontract machining offers precision that is hard to match with traditional manufacturing methods. CNC machines can achieve extremely tight tolerances. For Yigu Technology example, in high - end CNC machining, the tolerance can be as precise as ±0.0001 inches. This level of precision is crucial in industries such as aerospace, where a component might need to fit perfectly within a complex assembly to ensure the safety and efficiency of an aircraft. In a study by the Aerospace Industries Association, it was found that over 90% of aircraft - critical components that require a tolerance of less than 0.001 inches are produced using CNC machining.

Medical device manufacturing is another area where precision is non - negotiable. Implants like knee and hip replacements must be made with extreme accuracy to ensure patient comfort and proper functionality. A deviation of even 0.001 inches in the dimensions of a hip implant could lead to issues such as uneven wear, pain for the patient, and potentially the need for revision surgery. CNC machining ensures that these implants are made to the exact specifications required, reducing the risk of complications.

Consistent Quality Output

When it comes to quality consistency, CNC subcontract machining outperforms traditional methods, especially manual processing. Consider the following comparison between manual machining and CNC subcontract machining in terms of quality stability:

| Aspect | Manual Machining | CNC Subcontract Machining |

| Dimensional Accuracy | Varies greatly depending on the skill of the operator. Can have a tolerance range of ±0.01 - 0.1 inches. | Highly consistent, with a tolerance often within ±0.0001 - 0.001 inches. |

| Surface Finish | Inconsistent. Surface roughness can vary from part to part, and may require additional finishing steps. | Uniform surface finish. Advanced CNC machines can produce a surface finish with a roughness value (Ra) as low as 0.1 - 0.8 microns without extensive post - processing. |

| Repeatability | Difficult to achieve exact replication of parts. Each part may have slight differences in shape and size. | Excellent repeatability. Once the CNC program is set up, the machine can produce identical parts with minimal variation. |

For example, in the automotive industry, where thousands of identical parts need to be produced for vehicle assembly, CNC - machined parts ensure that each component fits perfectly, reducing the risk of assembly line issues and improving the overall quality and reliability of the vehicle. A car manufacturer may produce tens of thousands of engine blocks annually. With CNC subcontract machining, they can be confident that each engine block has the same high - quality finish and dimensional accuracy, leading to better engine performance and fewer warranty claims.

Cost - Efficiency

Reducing Labor Costs

One of the significant cost - saving aspects of CNC subcontract machining is its ability to reduce labor costs. Traditional machining processes often rely heavily on skilled manual labor. For example, in manual milling, an operator needs to constantly monitor and adjust the machine during the entire machining process. This not only requires a highly trained operator but also means that the operator can only work on one machine at a time.

In contrast, CNC machines are automated. Once the program is set up, the machine can run unattended for long periods. A single operator can oversee multiple CNC machines simultaneously. A study by the Manufacturing Institute found that in a typical manufacturing facility, the use of CNC machines can reduce the labor force required for machining operations by up to 50%. This reduction in labor not only cuts down on the cost of salaries and benefits but also minimizes the risk of human - error - related rework, which further saves costs.

Minimizing Material Waste

CNC technology is highly precise in material cutting, which significantly reduces material waste. Consider a scenario in the production of small metal brackets for electronic devices. In traditional machining, the operator may have to make rough cuts first and then gradually refine the shape. This often leads to over - cutting, where more material is removed than necessary.

However, with CNC machining, the machine follows the exact cutting path defined in the CAD model. For instance, a CNC laser cutting machine can cut a sheet of metal with an accuracy of up to 0.1 mm. This precision ensures that the amount of material removed is minimal and exactly as per the design requirements. A case study by a leading electronics manufacturer showed that after switching to CNC subcontract machining for their metal parts production, they were able to reduce material waste by 30%. This reduction in waste directly translates into cost savings, as less raw material needs to be purchased over time.

Production Efficiency and Flexibility

Faster Turnaround Times

CNC subcontract machining can significantly reduce production lead times compared to traditional machining methods. Take the production of a complex mechanical part for the automotive industry as an example. In a traditional machining setup, the process might involve multiple manual operations. First, an operator would need to manually set up the machine for each operation, such as milling, drilling, and turning. Each setup could take several hours, especially when dealing with complex geometries. Then, during the machining process, the operator has to constantly monitor and adjust the machine, which slows down the overall production speed. For a batch of 100 such parts, it could take up to a week to complete the production.

However, with CNC subcontract machining, the entire process is much more streamlined. Once the CAD model is created and the G - code is generated, the CNC machine can start production immediately. The machine can perform multiple operations in one setup, thanks to its multi - axis capabilities. For the same batch of 100 automotive parts, a CNC - equipped manufacturing facility can often complete the production in just 2 - 3 days. This is because the machine can run continuously for long periods, with only short breaks for tool changes and maintenance checks. This reduction in production time not only allows companies to meet tight deadlines but also enables them to respond more quickly to market demands.

Adaptability to Different Projects

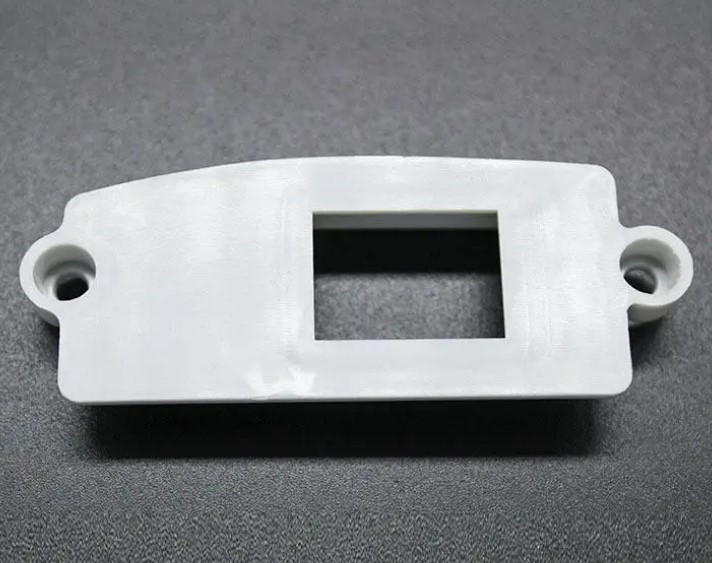

CNC subcontract machining is highly adaptable to a wide range of projects, regardless of the industry or the complexity of the parts. In the medical device industry, for instance, the production of custom - made surgical instruments requires a high level of precision and the ability to work with various materials, such as stainless steel, titanium, and special alloys. CNC machines can easily handle these different materials, and the programming flexibility allows for the creation of complex shapes and features. A company might need to produce a new type of forceps with a unique jaw design for a specific surgical procedure. The CNC subcontractor can quickly modify the existing CAD model and generate the appropriate G - code to produce the customized forceps, without the need for extensive re - tooling.

In the aerospace industry, where parts need to be both lightweight and strong, CNC machining can work with materials like aluminum - lithium alloys. For large - scale components such as aircraft wing spars or engine casings, 5 - axis and even 6 - axis CNC machines can be used to create the complex curved surfaces and internal structures required. These machines can move the cutting tool in multiple directions simultaneously, which is essential for machining such intricate parts. On the other hand, for small - scale, high - precision components like sensor housings, the same CNC technology can be used to achieve the required tight tolerances. Whether it's a large - scale industrial project or a small - scale, high - precision job, CNC subcontract machining offers the versatility to handle it all.

Yigu Technology's Perspective

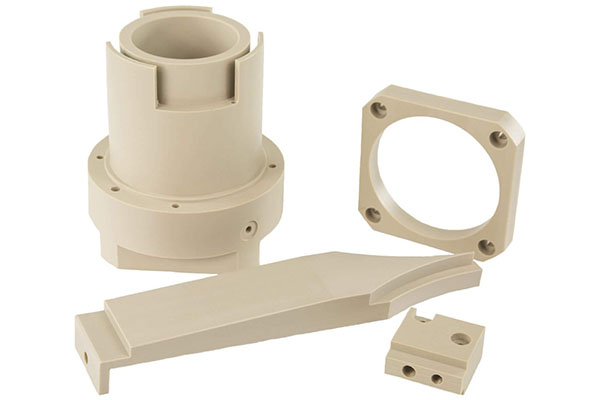

As a non - standard plastic and metal products custom supplier, Yigu Technology firmly believes in the pivotal role of CNC subcontract machining in service industries. Our experience has shown us that the precision and flexibility offered by CNC subcontract machining are invaluable. We've seen how it enables us to provide highly customized solutions for our clients.

For Yigu Technology example, in the medical device sector, we've used CNC machining to create intricate plastic components for diagnostic equipment. The ability to work with different plastics, from biocompatible materials to high - strength engineering plastics, allows us to meet the diverse needs of our medical clients. And in the automotive industry, when producing metal brackets and fixtures, the high - precision capabilities of CNC machining ensure that our products fit perfectly into complex vehicle assemblies. This not only reduces the time spent on trial - and - error during installation but also enhances the overall quality and performance of the vehicles. We are committed to leveraging CNC subcontract machining to offer top - notch custom products that drive the success of service industries we serve.

FAQ

What types of service industries can most benefit from CNC subcontract machining?

The aerospace, healthcare, and automotive industries are among the biggest beneficiaries. In aerospace, the need for high - precision and reliable components for flight safety makes CNC - machined parts essential. For example, engine components require tight tolerances to ensure efficient fuel combustion and optimal performance. In healthcare, surgical instruments and prosthetics need extreme precision to ensure patient well - being. A misaligned surgical tool can lead to surgical complications, while an ill - fitting prosthetic can cause discomfort. The automotive industry benefits from CNC subcontract machining for mass - producing high - quality parts. With thousands of identical parts needed for vehicle assembly, CNC - machined parts ensure perfect fits and reduce assembly line issues.

How does CNC subcontract machining ensure product quality?

CNC machining ensures product quality in several ways. First, it offers unparalleled precision. CNC machines can achieve tight tolerances, often as precise as ±0.0001 inches in high - end machining. This is crucial for industries with strict requirements. Second, the consistency of output is excellent. Once the CNC program is set up, the machine can produce identical parts with minimal variation. In contrast to manual machining, where the skill of the operator can lead to inconsistent results, CNC machining's automation ensures that each part has the same high - quality finish and dimensional accuracy. Additionally, modern CNC machines often have built - in sensors and monitoring systems that can detect any anomalies during the machining process, such as tool wear or vibrations, allowing for immediate adjustments to maintain quality.

Is CNC subcontract machining cost - effective for small - scale projects?

Yes, CNC subcontract machining can be cost - effective for small - scale projects. While the initial setup cost for programming the CNC machine might seem high, it is offset in several ways. Labor costs are reduced since a single operator can oversee multiple machines. Material waste is minimized due to the high precision of CNC cutting, which is beneficial even for small quantities. Also, the time saved in production can be significant. For example, a small - scale project for custom - made mechanical parts for a research device can be completed much faster with CNC machining compared to traditional methods. The ability to produce parts with high precision on the first try reduces the need for rework, further saving costs. In the long run, the quality and speed offered by CNC subcontract machining can provide good value for small - scale projects.