In today's accelerated product research and development iteration, enterprises have put forward higher requirements for precision, speed and flexibility in prototype manufacturing. CNC prototyping services, as the core supporting technology of modern industry, are becoming an innovation engine in various fields such as automotive, medical, aerospace, and other fields with their unique advantages. This article will comprehensively break down the value of CNC prototyping services from three dimensions: core concepts, application scenarios, and material processes.

1. CNC Prototyping: Basic Knowledge and Core Strengths

(1) CNC machining principle: precision machining driven by digital commands

The core of CNC (Computer Numerical Control) machining is to generate instructions such as G code and M code through computer programming to control the spindle, tools, and worktable of the machine tool for automated movement. The principle can be simply summarized as four major links: first, the three-dimensional modeling of the product is completed through CAD software, then the process planning and path simulation are carried out by CAM software, and finally the CNC machine tool cuts and processes raw materials such as metals and plastics into prototypes that meet the design requirements according to preset instructions. This digital control method completely gets rid of the dependence on manual operation for traditional processing and realizes the precise and controllable processing process.

(2) CNC prototyping process: full-link disassembly from design to finished product

A complete CNC prototyping process consists of 6 key steps, each directly impacting the quality of the final prototype:

- Design review: check the machinability of CAD drawings and optimize complex structures (such as internal corner radius, hole distribution);

- Material selection: choose metal (aluminum alloy, stainless steel) or plastic (nylon, PEEK) materials according to the prototype use;

- Programming Simulation: Plan cutting paths through CAM software to simulate the machining process to avoid collision risks;

- Machine Machining: After fixing the raw materials, start the CNC machine for automated cutting;

- Post-processing processing: including deburring, grinding, heat treatment, etc., to improve the surface quality and mechanical properties of the prototype;

- Accuracy Inspection: Use CMMs, laser scanners, and other equipment to verify that the prototype dimensional tolerance meets the design standard (usually within ±0.005mm).

(3) CNC Rapid Prototyping Advantages: Why Is It a Top Choice for Businesses?

The core advantages of CNC prototyping services over traditional machining methods are reflected in four aspects:

- High precision: Digital control enables machining tolerances up to ±0.005mm, meeting the prototype needs of precision parts;

- High efficiency: 30%-50% shorter processing time for a single process than traditional milling machines, and 24-hour uninterrupted production of complex prototypes;

- High flexibility: modify the processing instructions to adapt to different design schemes, without the need to remake the mold, and support small batch and multi-variety production;

- Low cost: Reduced manual intervention reduces scrap rates, and low-volume prototyping costs are more than 60% lower than mold opening.

(4) CNC vs. Traditional Machining: The gap brought about by technological innovation

To more visually demonstrate the advantages of CNC machining, here is its core comparison with traditional machining (milling machines, lathes):

| Contrast dimensions | CNC machining | Traditional processing |

| Processing principle | Digital instruction automation control | Manual operation of machine tools for manual processing |

| Accuracy level | ±0.005mm-±0.01mm | ±0.05mm-±0.1mm |

| Production efficiency | high, support batch automated processing | low, relying on worker skill proficiency |

| Complex machining capabilities | It can process complex surfaces and polyhedra | Weak, difficult to achieve high-precision complex structures |

| Labor costs | Low, 1 person can operate multiple machine tools | high, senior skilled workers are required to be on duty throughout the process |

| Applicable scenarios | Precision prototypes, small batch production | Simple parts, large-scale standardized production |

(5) CNC Prototype Accuracy and Speed: How to Achieve "Fish and Bear's Paws"?

The key to CNC prototyping ensuring both accuracy and speed lies in two major technical supports: high-precision machine tool configuration (such as linear motor drive, grating ruler closed-loop control), and optimized machining strategies. For example, when machining complex surfaces, the step-by-step strategy of "roughing - semi-finishing - finishing" is adopted: roughing quickly removes excess material (feed rate up to 5000mm/min), and finishing uses small cutting volume and high speed (up to 24000rpm) to ensure precision. A practical case shows that a prototype of an aerospace component can be completed in just 8 hours through CNC machining, compared to 3 days for traditional machining, and the dimensional tolerance is controlled within ±0.008mm, fully meeting the needs of subsequent testing.

2. CNC Prototype Service: Analysis of application cases in diverse fields

(1) CNC auto parts prototypes: Accelerate the iteration of new car research and development

With long R&D cycles and high testing requirements in the automotive industry, CNC prototyping has become the key to shortening R&D cycles. For example, when developing a new type of gearbox, a new energy vehicle company needs to make prototypes of 12 core components such as gears and housings. With CNC machining, the full set of prototypes was produced in just 2 weeks, saving 3 months compared to the traditional mold opening method. These prototypes have been bench tested and road tested, verifying the feasibility of the design and laying the foundation for subsequent mass production. Additionally, CNC machining can be used for prototyping automotive interior parts, lamp brackets, and more, enabling designers to quickly adjust shapes and structures.

(2) CNC medical device prototypes: precise protection to protect life and health

Medical devices require high levels of biocompatibility, precision, and stability in prototypes. A medical device company developed a new minimally invasive surgical device using CNC machined stainless steel and titanium prototypes. These prototypes needed to meet the requirements of "no burrs, surface roughness Ra≤0.8μm, and dimensional tolerance ±0.01mm", and were fully met by multi-axis CNC machine machining and precision polishing to medical standards. After clinical testing, the prototype device has been recognized by doctors for its operational flexibility and safety, and is now in mass production. Additionally, CNC prototypes are widely used in the research and development of prosthetics, implants, and other products.

(3) CNC Aerospace Prototype Cases: Breaking through the technical challenges of extreme environments

Parts in the aerospace field need to withstand extreme environments such as high temperatures, high pressures, and high loads, making prototyping extremely difficult. When developing satellite antenna mounts, an aerospace company chose high-strength aluminum alloy materials to complete the forming of complex curved surfaces through 5-axis CNC machining. The prototype requires a machining accuracy of ±0.005mm and needs to be lightweight (weight ≤ 200g). By optimizing the cutting path and adopting high-speed cutting technology, the prototype that meets the requirements was finally successfully produced, and after mechanical testing and space environment simulation testing, all indicators met the design standards. CNC prototyping not only shortens R&D cycles but also reduces the waste of expensive materials.

(4) CNC Consumer Electronics Prototypes: Leading the way in the fusion of fashion and functionality

Consumer electronics are rapidly changing, and consumers have higher and higher requirements for the appearance and performance of products. When developing a new flagship phone, a mobile phone manufacturer needs to make a prototype of a metal middle frame and a camera module bracket. Through CNC machining, the integrated molding of the middle frame is realized, which not only improves the structural strength but also ensures the flatness and gloss of the appearance. After the prototype is made, designers can quickly conduct feel testing and assembly verification, and adjust the size and shape in time. Additionally, CNC prototypes are used in the production of shells and internal structural parts for products such as headphones and smartwatches, supporting low-volume customized production.

(5) CNC industrial equipment prototyping: consolidate the foundation of intelligent manufacturing

The stability and durability of industrial equipment directly impact production efficiency, and CNC prototyping provides a reliable guarantee for equipment research and development. When developing a new robotic arm, an automation equipment company needs to prototype key components such as joints and connecting rods. CNC machined stainless steel and engineering plastic prototypes were used to verify the flexibility and load capacity of the mechanical structure through assembly testing. The prototype was tested for 100,000 cycles without any problems, providing strong support for subsequent mass production. In addition, CNC prototypes are widely used in the research and development of machine tool accessories, conveying equipment and other products, helping enterprises quickly respond to market demands.

3. CNC Prototype Materials and Processes: Core Points of Careful Selection

(1) CNC machining materials (metal/plastic): selection guide and characteristic analysis

Choosing the right machining material is key to ensuring the quality of CNC prototypes, and different materials vary greatly in terms of machining difficulty, performance, and applicable scenarios:

- Metal Material:

- Aluminum alloy (6061, 7075): light weight, high strength, good processing performance, suitable for automobile and aerospace parts prototypes;

- Stainless steel (304, 316): corrosion resistance, high hardness, suitable for medical devices and industrial equipment prototypes;

- Titanium alloy: high strength and good biocompatibility, but difficult to process and high cost, mostly used in high-end medical and aerospace products.

- Plastic Materials:

- Nylon (PA6, PA66): good toughness, strong wear resistance, suitable for gears, bearings and other transmission component prototypes;

- PEEK: High temperature resistance, chemical corrosion resistance, suitable for prototypes of parts in high temperature environments;

- ABS: Low cost, easy to process, suitable for appearance parts and simple structural prototypes.

(2) CNC Aluminum Alloy Prototyping: Process Key Points and Advantages

Aluminum alloys are the most commonly used material in CNC prototyping, and there are three core takeaways to their crafting process:

- Blank selection: Select extruded profiles, plates, or forgings according to prototype dimensions to reduce machining allowances;

- Cutting parameters: high feed rate (3000-5000mm/min) and large cutting depth for roughing processing, high speed (15000-24000rpm) and small cutting depth for finishing;

- Cooling method: Use emulsion or cutting oil to cool to avoid aluminum alloy sticking and deformation.

The advantages of aluminum alloy prototypes are "light weight and high strength", and the processing cost is relatively low, making them widely used in many fields. For example, the frame prototype of a drone company is CNC machined with aluminum alloy material, weighing only 150g but being strong enough to withstand a load of 20kg.

(3) CNC stainless steel machining technology: technical solutions for high hardness

Stainless steel has high hardness, strong toughness, and is difficult to process, so it needs to use targeted technology:

- Tool selection: Use carbide tools or diamond-coated tools to improve cutting wear resistance;

- Cutting parameters: reduce the cutting speed (80-150m/min), increase the feed rate, and avoid too fast tool wear;

- Chip evacuation treatment: The high-pressure cooling system is used to discharge chips in time to prevent chips from scratching the surface of the workpiece.

A prototype stainless steel valve from a food machinery company successfully controlled the surface roughness to Ra≤0.4μm by optimizing the processing process, meeting food hygiene standards.

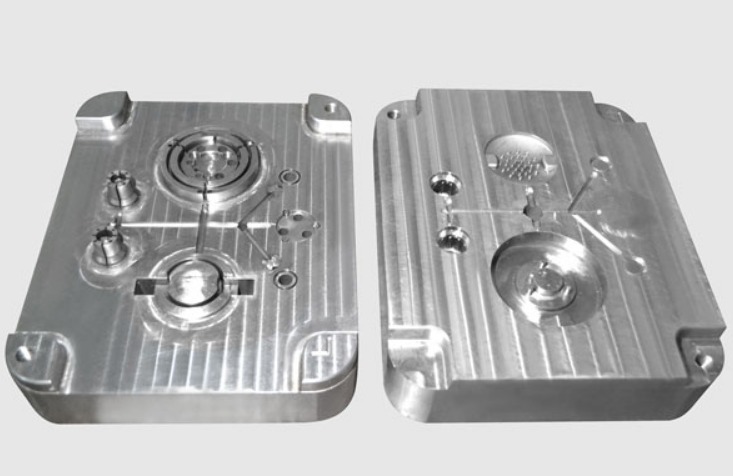

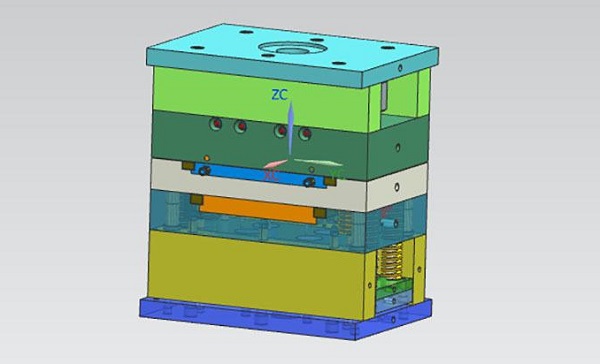

(4) CNC Multi-Axis Machining Technology: Breaking through the machining limitations of complex structures

Multi-axis machining (4-axis, 5-axis) is one of the core technologies of CNC prototyping, and its advantage lies in its ability to machine complex surfaces and polyhedra without the need for multiple clamping. For example, the spindle of a 5-axis CNC machine can rotate around the X, Y, and Z axes, and can cut from any angle, making it suitable for the production of complex prototypes such as aerospace components and medical devices. A mold company's complex cavity prototype can complete the entire process in just one clamping through 5-axis CNC machining, reducing the machining time by 40% and greatly improving dimensional accuracy.

(5) CNC Surface Finishing Options: Enhance prototype performance and appearance

Surface finishes for CNC prototypes not only improve appearance but also enhance mechanical properties and longevity, with common options including:

- Grinding / Polishing: Removing machining marks and improving surface finish (Ra≤0.2μm);

- Sandblasting: Forms a uniform matte effect on the surface and enhances adhesion;

- Electroplating: Plating a layer of chromium, nickel and other metals on the surface of the metal prototype to improve corrosion resistance and wear resistance;

- Anodizing: For aluminum alloy prototypes, an oxide film is formed, which can be dyed to achieve a variety of colors;

- Spraying: Suitable for plastic prototypes, improving surface hardness and weather resistance.

When choosing a surface treatment method, it is necessary to determine the purpose and material properties of the prototype. For example, medical device prototypes often use passivation treatment to improve corrosion resistance; consumer electronics prototypes often use anodizing or spraying to enhance the appearance and texture.

4. Yigu Technology's view

As a company specializing in CNC prototyping services, Yigu Technology believes that the core value of CNC prototyping lies in "quickly verifying designs, reducing R&D risks, and accelerating product launch." Under the trend of intelligent manufacturing, CNC prototyping is moving towards "higher precision, faster speed, and more flexible customization." In the future, with the deep integration of AI technology and CNC machining, machining path optimization and quality prediction will be intelligent, further improving the efficiency and reliability of prototyping. We recommend that when choosing CNC prototyping services, enterprises should not only pay attention to the accuracy and price of the equipment, but also pay attention to the technical experience, case accumulation, and customization capabilities of the service provider in order to truly play the innovative and enabling role of CNC prototyping.

5. FAQ

- What is the typical lead time for CNC prototyping?

A: 1-3 days delivery for regular simple prototypes, 5-7 days for complex multi-part prototypes, and 24 hours for expedited orders.

- What is the maximum machining size limit for CNC prototypes?

A: Different machines have different machining ranges, with conventional machines capable of processing ≤ 1000mm×600mm×500mm workpieces, while large CNC machines can support larger-size prototyping.

- Is there a significant difference in CNC machining costs for plastic and metal materials?

A: The machining cost of metal materials, especially titanium alloys, is 2-5 times higher than that of plastics at the same size, mainly due to high metal hardness, long machining time, and large tool loss.

- Can CNC prototypes be used directly for mass production?

A: Some simple prototypes can be mass-produced in small batches (within 100 pieces), and it is recommended to use more economical methods such as mold opening for mass production; Precision parts prototypes are validated and ready for low-volume delivery.

- How to ensure the machining accuracy of CNC prototypes?

A: Choose a high-precision CNC machine equipped with a grating ruler, linear motor; Path optimization with CAM software; Tool calibration and workpiece alignment before machining; After processing, the accuracy is tested by CMM and other equipment.