Introduction: Why is the choice between forward and backmilling crucial?

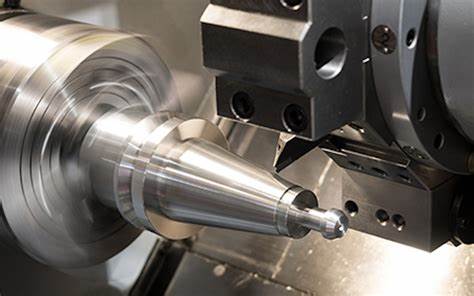

In CNC milling, up milling and down-milling are used They are the two most basic and core cutting methods. The seemingly simple difference in cutting direction directly affects the surface quality, tool life, machine stability and even production cost - according to industry statistics, choosing the right milling method can extend tool life by 30%-50% and increase machining efficiency by more than 20%. Whether it is processing common metals such as aluminum alloys and stainless steel, or special workpieces such as thin-walled parts and composite materials, correctly distinguishing and choosing forward or reverse milling is a necessary core skill for senior engineers. This article will comprehensively dismantle the key knowledge points of forward milling and reverse milling from basic definitions to practical cases, helping you completely solve the core question of "which milling method to choose".

1. Forward milling and reverse milling: basic concept and core difference

To choose the right milling method, you must first understand their essential differences. In this part, we use plain language + intuitive comparison from the three dimensions of definition, working principle and core distinction to help you quickly understand.

1. Core definition disassembly

- Definition of forward milling: When the direction of rotation of the milling cutter is the same as the feed direction of the workpiece, it is called forward milling. Simply put, the milling cutter "pushes" the workpiece forward and the cutting force direction is in line with the feed direction.

- Reverse milling definition: When the rotation direction of the milling cutter is opposite to the feed direction of the workpiece, it is called reverse milling. At this point, the milling cutter "pulls" the workpiece and the cutting force direction is opposite to the feed direction.

2. Comparison table of key differences

| Contrast dimensions | Up milling | Down milling |

| Milling direction | The milling cutter rotates in the same direction as the feed direction | The milling cutter rotates in the opposite direction to the feed direction |

| Cutting force direction | Pointing inside the workpiece, the vertical force is divided to press down on the workpiece | Pointing to the outside of the workpiece, the vertical force lifts the workpiece upwards |

| Cutting thickness variations | Gradually decrease from maximum to zero | Gradually increase from zero to maximum |

| The cut-in state | The blade cuts directly into the workpiece without slippage | The blade slides first and then cuts, and there is squeezing friction |

| Machine load performance | The spindle load is relatively stable | The spindle load fluctuates greatly |

Practical Tips: When judging forward and backward milling, you can observe the direction of movement at the moment of contact between the milling cutter blade and the workpiece - the cutting edge "follows" the workpiece when milling forward, and the cutting edge "faces" the workpiece when reverse milling.

2. Characteristics competition: detailed explanation of the advantages and disadvantages of forward milling and reverse milling

After understanding the basic concepts, the core is to grasp the advantages and disadvantages of the two methods, which is the key basis for selection. The following is a detailed analysis of the performance of the two in terms of processing quality, tool life, stability, etc. in combination with actual machining scenarios.

1. Advantages and disadvantages of trim milling

- Core Benefits:

- Higher surface finish: the cutting thickness ranges from large to small during trim milling, and there is no slip friction between the cutting edge and the workpiece, which can effectively reduce the surface roughness, and the Ra value can be as low as 0.8μm or less (suitable for finishing).

- Less tool wear: the cutting force is concentrated in the middle of the cutting edge, avoiding severe friction on the edge of the cutting edge, and the carbide tool life can be extended by more than 30%;

- Higher processing efficiency: the cutting force is consistent with the feed direction, the machine tool consumes less power, and the feed speed can be increased under the same working conditions.

- Main disadvantages:

- High requirements for machine tool rigidity: periodic shock load will be generated during forward milling, and vibration is easy to cause if the machine tool is not rigid enough;

- Easy to produce edges: When the cutting temperature is low, the chips are easy to adhere to the cutting edge to form edges, affecting the machining accuracy.

- Strict requirements for workpiece clamping: vertical force pressure downwards, but if the clamping is not firm, it may lead to workpiece displacement.

2. Advantages and disadvantages of reverse milling

- Core Benefits:

- Stronger processing stability: the cutting force lifts the workpiece upwards, reducing the extrusion of the cutting edge and the workpiece, and can be processed smoothly even if the rigidity of the machine tool is average;

- Not easy to gnaw the knife: the cutting edge slides first and then cuts in during reverse milling, which avoids the phenomenon of "gnawing the knife" that may occur in forward milling, and is suitable for processing materials with uneven hardness;

- Low requirements for clamping: the vertical force is upward, and the workpiece is not easy to be displaced due to loose clamping, which is suitable for large or irregular workpieces.

- Main disadvantages:

- Poor surface finish: The friction generated during the blade slip process can lead to increased surface roughness, with Ra values typically above 1.6μm;

- Serious tool wear: the cutting thickness increases from zero, the edge of the cutting edge bears the maximum cutting force, and it is easy to chip, and the tool life is 20%-30% shorter than that of forward milling;

- High power consumption: The cutting force is opposite to the feed direction, and the machine needs to overcome additional resistance, resulting in higher energy consumption.

3. Milling according to the material: applicable scenarios and material selection guidelines

The key to choosing between forward and backmilling is "adaptation" – a decision based on the material, workpiece type, and machining stage. The following is a detailed explanation of the scenarios to help you quickly get into the seat.

1. Select by material type

- Suitable materials for trim milling:

- Metals with good plasticity: such as aluminum alloy, copper alloy, mild steel, etc., trim milling can reduce material deformation and improve surface quality;

- Composite materials: For example, carbon fiber composites, trim milling can avoid material delamination and reduce fiber tearing.

- Reverse milling suitable materials:

- Metals with high hardness: such as stainless steel, high carbon steel, hardened steel, etc., the smooth cutting of reverse milling can reduce tool chipping;

- Brittle materials: such as cast iron, ceramics, etc., reverse milling can avoid material chipping and improve processing stability.

Practical case: When machining 6061 aluminum alloy thin-walled parts, forward milling + high-speed cutting (rotation speed 3000rpm, feed 0.2mm/r) is adopted, the surface roughness can reach Ra0.4μm, and the deformation of the part is controlled within 0.02mm; while when machining 304 stainless steel molds, reverse milling + low-speed large cutting depth (rotation speed 800rpm, cutting depth 5mm) is adopted, and the tool life is 40% longer than that of forward milling.

2. Select by processing scenario

- Rough machining: Prefer reverse milling. The smoothness of reverse milling is more suitable for removing a large amount of allowance, even if there is a slight vibration, it will not affect the subsequent finishing, and the clamping requirements are low, and the efficiency is higher.

- Finishing: Prefer up milling. The advantages of high surface finish of trim milling can meet precision requirements, especially suitable for parts with high surface quality requirements (such as mold cavities, aerospace parts surface);

- Milling strategy for thin-walled parts: Forward milling must be selected. The downward compression force of down-milling can reduce the vibration and deformation of thin-walled parts, and with the parameters of small depth of cut and high feed, the accuracy of the parts can be effectively controlled.

- Intermittent cutting scenario: Choose reverse milling. The cutting edge of reverse milling has a gentler cutting method, which can avoid the impact load during intermittent cutting and protect the tool.

4. Parameter optimization: cutting parameter setting skills for forward and reverse milling

After choosing the right milling method, parameter settings directly affect the machining effect. The following shares the core parameters (speed, feed, depth of cut) setting principles of different milling methods, as well as vibration control and efficiency optimization techniques.

1. Core cutting parameter setting

| Milling method | Speed (S) setting principle | Feed rate (F) setting principle | Depth of Cut (AP) selection |

| Follow milling | Higher rotational speeds (10%-20% higher than reverse milling) reduce built-up edges | High feed (0.15-0.3mm/r) for increased efficiency | Small Depth of Cut (0.1-0.5mm for Finishing, 1-3mm for Roughing) |

| Reverse milling | Lower speed (to avoid overheating of the cutting edge) | Medium feed (0.1-0.2mm/r) for balanced stability | Large depth of cut (rough 3-8mm) to make the most of the cutting edge |

2. Vibration control methods

- Vibration control along the milling: If the rigidity of the machine tool is insufficient, the feed speed can be reduced by 10%-15%, or an unequal pitch milling cutter can be used to reduce resonance;

- Reverse milling vibration control: increase the cutting speed, reduce the slip time between the cutting edge and the workpiece, and check the tool runout to ensure that it does not exceed 0.02mm.

3. Machining efficiency optimization skills

- Forward milling optimization: Adopting high-speed cutting (HSC) technology, the machining speed of aluminum alloy can reach 3000-6000rpm, with oil mist cooling, to reduce the accumulation of edges;

- Reverse milling optimization: Adopting large cutting depth + layered cutting, stainless steel machining depth can reach 5-8mm, each layer cutting depth 2-3mm to avoid tool overload.

5. CNC programming and operation: a practical guide to forward and backmilling

After mastering the theory, programming and operation at the practical level are the key. This part shares instruction implementation, path design, and operation precautions in CNC programming to help you quickly implement it.

1. CNC forward milling and reverse milling programming

- G-code direction control: through G01 (linear interpolation) with the rotation direction of the tool, forward and reverse milling switching;

- Programming skills: "clockwise" toolpath (inner contour machining) is used for forward milling, and "counterclockwise" toolpath is used for reverse milling to avoid tool interference;

- Sample code:

//Parallel milling programming (inner contour machining) G90 G54 G00 X10 Y10 Z5; G01 Z-5 F100; G41 D01 X20 Y20 F200; //Clockwise cutting, forward milling//reverse milling programming (outer contour machining) G90 G54 G00 X50 Y50 Z5; G01 Z-5 F100; G42 D01 X60 Y60 F200; //Counterclockwise cutting, reverse milling2. Toolpath design principles

- Along the milling path: try to use "spiral feeding" or "oblique feeding" to avoid gnawing caused by vertical downcutting;

- Reverse milling path: "straight line feeding" is adopted, and the feed point selects the edge of the workpiece to reduce the slip distance of the cutting edge;

- Switching tips for switching from roughing to finishing: When roughing to finishing, switch by adjusting the direction of the toolpath to ensure that the finishing is done with forward milling.

3. Key points of CNC machine tool setup

- Check the rigidity of the machine tool: confirm the clearance of the machine tool guide rail and the stiffness of the spindle before milling, and adjust the preload of the lead screw if necessary;

- Cooling method selection: oil mist cooling (aluminum alloy) or emulsion (steel parts) for forward milling, high-pressure cooling for reverse milling to reduce the cutting temperature;

- Tool selection: Forward milling gives priority to tools with sharp edges (such as coated carbide tools), and reverse milling uses tools with good toughness (such as tungsten steel tools).

6. Industry application cases: practical scenarios of forward and reverse milling

Combining theory with practice is the last word. Here are 3 typical industry cases to see how senior engineers choose milling methods.

1. Mold manufacturing case: high-precision cavity machining

- Workpiece: P20 mold steel cavity (hardness HRC30-35), surface Ra0.8μm required;

- Options: roughing reverse milling (cutting depth 5mm, speed 1000rpm, feed 0.15mm/r), finishing forward milling (cutting depth 0.3mm, speed 1500rpm, feed 0.2mm/r);

- Results: 30% more roughing efficiency, up to standard finishing surface quality, and 40% longer tool life.

2. Aerospace Cases: Machining of aluminum alloy thin-walled parts

- Workpiece: 7075 aluminum alloy spar (wall thickness 2mm), required deformation ≤ 0.03mm;

- Selection: Full forward milling (rotation speed 4000rpm, feed 0.25mm/r, cutting depth 0.5mm);

- Effect: The deformation of the parts is controlled within 0.02mm, and the surface Ra0.4μm meets aviation standards.

3. Auto parts case: stainless steel gear processing

- Workpiece: 304 stainless steel gear (hardness HB201-245), requiring tooth surface accuracy IT7;

- Selection: Reverse milling (rotation speed 800rpm, feed 0.12mm/r, cutting depth 3mm);

- Effect: Vibration and cutter gnawing during forward milling are avoided, the tooth surface accuracy is up to standard, and the tool life is 35% longer than that of forward milling.

7. Yigu Technology's view

The essence of the choice between forward and reverse milling is the art of "adapting to working conditions" - there is no absolute advantage or disadvantage, only whether it is suitable. In actual processing, the milling method should be determined based on material characteristics and processing requirements, and then the shortcomings of a single method should be compensated through parameter optimization and programming skills. With the development of intelligent manufacturing, the rigidity and precision of CNC machine tools continue to improve, and the application scenarios of forward milling will become more and more extensive, but reverse milling is still irreplaceable in scenarios such as high-hardness materials and rough machining. It is recommended that engineers accumulate more data in practice, establish a matching library of "material-working conditions-milling method", and pay attention to the progress of tool technology (such as coating tools, unequal pitch tools) to further improve machining efficiency and quality.

8. FAQ

- Is surface quality necessarily better than backmilling?

Not necessarily. If the hardness of the machining material is high (such as HRC45 or above), forward milling can easily lead to tool chipping, and the surface quality is not as good as reverse milling; only when the material has good plasticity and the machine tool is rigid enough, the surface quality advantage of forward milling will be revealed.

- Can thin wall parts only be processed with trim milling?

Forward milling is preferred, but if the rigidity of the machine tool is insufficient, the combination of "reverse milling + small depth of cut + high feed" can be used to reduce vibration; at the same time, it is optimized with fixtures (such as vacuum adsorption) to control the deformation of the part.

- How to quickly switch forward and backward milling in CNC programming?

The core is to adjust the direction of the tool path: when machining the inner contour, the clockwise pass is forward milling, and the counterclockwise is reverse milling; When the outer contour is machined, the counterclockwise turn is forward milling, and the clockwise is reverse milling. It is also possible to switch directions with G41/G42 tool radius compensation.

- Which milling method to choose for machining composite materials (e.g. carbon fiber)?

Priority is given to post milling, with diamond-coated tools, which can reduce fiber tearing and delamination; The cutting depth is controlled at 0.1-0.3mm, and the feed speed is 0.1-0.15mm/r to avoid overheating of the tool.