In the highly competitive automotive manufacturing industry, the quality of parts directly determines the performance, safety and durability of the whole vehicle. Automotive machining services, as the core link connecting design and mass production, have become a key factor for auto enterprises to gain market advantages. But how to select a service provider that can meet high precision, strict standards and customized needs? This article will comprehensively analyze from four dimensions: core services, technical capabilities, quality control and integrated solutions, to help you make wise decisions.

Core Services: Precision Machining of Auto Parts

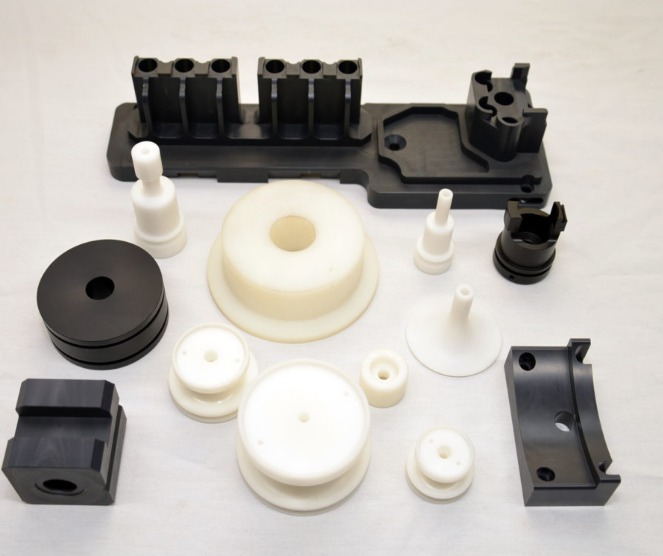

The core of automotive machining services lies in the precision processing of key components, and each part is related to the stable operation of the vehicle. Here are the most critical processing categories in the industry:

- Engine cylinder block machining: The engine cylinder block is the "heart" of the car, and its machining precision directly affects the engine's power output and fuel consumption. A qualified cylinder block needs to ensure the parallelism of the cylinder bore and the flatness of the joint surface, with a tolerance control within ±0.005mm. For example, a well-known commercial vehicle manufacturer once cooperated with a machining service provider to optimize the cylinder block processing process, reducing the engine vibration rate by 15% and improving the fuel efficiency by 8%.

- Processing of gearbox housing: The gearbox housing bears the installation and operation of internal gears and shafts, requiring high rigidity and dimensional accuracy. The processing needs to focus on the position accuracy of the bearing hole system, to avoid gear jamming caused by offset.

- Turbocharger component processing: Turbocharger components work in high temperature and high speed environment, which requires the machining service provider to have the ability of processing high-temperature alloy materials, and control the dynamic balance of the turbine rotor within the range of 0.5g·mm.

- Manufacturing of brake system components: Brake discs, calipers and other components are related to driving safety, and the machining must meet the requirements of wear resistance and dimensional stability. The surface roughness of the brake disc after machining should be controlled at Ra0.8-Ra1.6.

- Machining of automotive structural components: Structural parts such as chassis cross members and suspension brackets need to bear heavy loads, so the machining process should ensure the consistency of material internal stress, avoid deformation during use.

- Precision machining of automotive aluminum alloy: Aluminum alloy materials are widely used in automotive lightweight design. Its machining needs to solve the problem of thermal deformation, usually using high-speed cutting tools and cooling lubrication technology to ensure the precision of parts.

Technical Capabilities: Advanced Machining Technology and Materials

Excellent core services are supported by strong technical capabilities. The competitiveness of automotive machining service providers is reflected in the mastery of advanced processes and the processing capacity of special materials:

| Processing Technology | Core Advantages | Application Scenarios |

|---|---|---|

| CNC Five Axis Machining | It can realize the processing of complex curved surfaces in one clamping, reduce the number of positioning times, and improve the processing precision by more than 30% | Turbocharger impellers, automotive molds, complex structural parts |

| High speed milling | High cutting speed, small cutting force, can obtain a good surface finish, and the processing efficiency is 2-3 times that of traditional milling | Thin-walled parts such as aluminum alloy gearbox housings |

| Automotive parts turning | Suitable for processing rotating parts, with high dimensional accuracy and good roundness | Shaft parts such as crankshafts and camshafts |

| Specialized fixtures for the automotive industry | Customized fixture design can improve the clamping stability and reduce the auxiliary time of processing by 20% | Batch processing of standardized parts such as brake calipers |

In terms of material processing, Aluminum magnesium alloy processing for automobiles has become a mainstream demand due to the trend of lightweight. In addition, Machining of cast iron and stainless steel is also the basic capability of service providers. For example, ductile iron is often used in engine cylinder blocks, and stainless steel is used in exhaust system parts. The processing of these two materials needs to select different cutting parameters and tool types.

In addition, Processing of automotive prototype parts is an important test of the service provider's R&D capability. Rapid prototype processing can help auto enterprises verify the design scheme in the early stage, shorten the product launch cycle. A new energy vehicle enterprise once completed the prototype processing of 50 kinds of key parts in 2 weeks through the rapid prototype service of a machining provider, and successfully launched the new model 3 months ahead of schedule.

Industry and Quality: Industry Standards and Quality Control

Automotive manufacturing is a highly standardized industry, and the machining service provider's compliance with quality standards is the bottom line of cooperation. The following points are the key to judging the quality control capability of service providers:

- IATF 16949 certification: This is the mandatory quality management system standard in the automotive industry, covering the whole process from design and development to after-sales service. Service providers with this certification have a complete quality control system, which can meet the strict requirements of auto OEMs. It is worth noting that the certification needs to be updated every 3 years, and the audit is strict, which can effectively reflect the long-term stability of the service provider's quality management.

- Automotive industry machining standards: In addition to IATF 16949, service providers also need to comply with the standards of different countries and regions, such as the ISO 9001 standard, the German VDA standard, etc. These standards specify the requirements for machining precision, material inspection and process documentation.

- Batch processing of automotive parts: Batch processing requires the service provider to have a mature production line management capability, to ensure the consistency of each part. For example, in the batch processing of 10,000 sets of brake calipers, the dimensional deviation between parts should be controlled within ±0.01mm.

- Automotive parts testing services: A professional service provider should be equipped with a complete set of testing equipment, such as three-coordinate measuring machines, roughness meters, hardness testers, etc. The inspection covers incoming material inspection, process inspection and final inspection. For key parts, 100% full inspection is required, while for general parts, sampling inspection is carried out according to the AQL standard.

- Durability testing of machined parts: Durability test is the key to verify the service life of parts. Common tests include fatigue test, corrosion resistance test and high temperature aging test. For example, suspension brackets need to pass 1 million times of fatigue load test without damage.

- Automotive supply chain machining: Excellent service providers can integrate into the automotive supply chain, realize synchronous R&D with OEMs, and respond to the demand change quickly. For example, when a car enterprise adjusts the design of the chassis parts, the service provider can adjust the processing process within 48 hours to ensure the supply cycle.

Solutions: Customized and Integrated Solutions

With the diversification of automotive market demand, a single machining service can no longer meet the needs of enterprises. Service providers that can provide customized integrated solutions have become the first choice of auto enterprises:

- Customized automotive parts processing: For some special models or innovative parts, service providers need to provide customized processing schemes. For example, a manufacturer of off-road vehicles needs a non-standard suspension bracket. The machining service provider can optimize the process according to the load characteristics of the part, adopt the integrated processing of forging and machining, and improve the part's bearing capacity by 25%.

- Automotive machining solutions: A complete solution should include pre-sales design consultation, process optimization, production manufacturing and after-sales service. Service providers can use digital simulation technology to predict possible problems in the processing process, and put forward improvement suggestions in advance.

- From design to processing services: The integrated service from design to processing can effectively reduce the communication cost between the two parties. The service provider's engineers can participate in the design stage of parts, put forward machining feasibility suggestions, avoid design schemes that are difficult to process or high in cost.

- Secondary processing of automotive components: Secondary processing such as surface treatment (electroplating, anodizing) and heat treatment (quenching, tempering) can improve the performance of parts. Service providers with secondary processing capabilities can save the time of parts transferring between different enterprises.

- Machining and assembly integration: Some service providers can provide integrated services of machining and assembly, which can directly deliver the assembled components to auto enterprises, reducing the enterprise's assembly pressure.

- Electric vehicle component processing: With the rapid development of new energy vehicles, the processing demand for electric vehicle components (such as motor shells, battery brackets) is increasing. These parts have high requirements for precision and corrosion resistance, and service providers need to master the corresponding processing technology.

Yigu Technology’s Perspective

As a professional provider of high-end CNC precision machining services, Yigu Technology believes that automotive machining services in the new era must take "precision, efficiency and customization" as the core. Facing the trend of automotive lightweight and electrification, we have optimized the processing technology of aluminum magnesium alloy and high-strength steel, and passed IATF 16949 certification to ensure that all products meet the industry standards. We focus on providing integrated solutions from design to assembly for customers, and customize exclusive processing schemes according to the characteristics of different parts. In the future, Yigu Technology will continue to invest in technological research and development, help the automotive manufacturing industry to upgrade with more efficient and precise machining services.

FAQ

- What is the core requirement of automotive machining services for precision?The core requirement is to control the tolerance of key parts within a small range, usually ±0.005mm-±0.01mm, and ensure the consistency of batch parts.

- Why is IATF 16949 certification important for machining service providers?IATF 16949 certification is the quality threshold for entering the automotive supply chain, which proves that the service provider has a complete quality management system and can meet the strict requirements of auto enterprises.

- How to solve the problem of thermal deformation in aluminum alloy parts processing?High-speed cutting tools, reasonable cooling and lubrication schemes, and segmented processing technology can be used to reduce the influence of cutting heat on parts.

- What advantages does CNC five-axis machining have in automotive parts processing?It can realize one-time clamping of complex parts, reduce positioning errors, improve processing precision and efficiency, and is especially suitable for processing parts with complex curved surfaces.