In the modern industrial system, machined metal has become the basic material to support the development of core industries due to its excellent mechanical properties, machinability and reliability. From aerospace equipment soaring in the sky, to cars galloping on the earth, to medical equipment that protects health, machined metals play an irreplaceable role. This article will focus on the three core areas of aerospace, automobile manufacturing, and medical equipment, and provide an in-depth analysis of the application logic, material selection, and practical cases of machined metals to help you fully grasp their core value in modern industry.

1. Introduction

1.1 Introduce the definition of machined metal

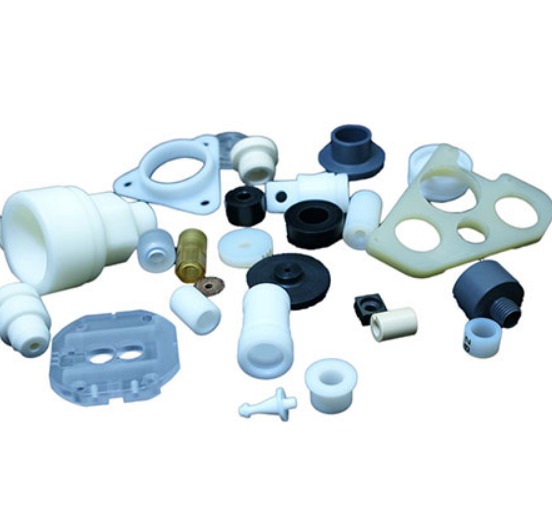

Machined metal refers to metal products or semi-finished products that change the shape, size and surface quality of metal materials through turning, milling, grinding, stamping and other machining processes to meet specific industrial needs. Its core feature is that it can accurately match the performance requirements of different working conditions, and achieve precise control of strength, precision, corrosion resistance and other indicators through material selection and process optimization, which is the key link connecting metal raw materials and industrial finished products.

1.2 The Importance of Machined Metals in Modern Industry

Machined metal is the "cornerstone" of modern industry, and its quality directly determines the performance and safety of the end product. According to industry data, about 65% of the core components in the global industrial field rely on machining metal manufacturing; In the field of high-end equipment, this proportion is as high as more than 80%. Whether it is precision structural parts in the aerospace field, core transmission components of automobiles, or implanted devices in medical equipment, they are inseparable from the support of machined metal. It can be said that the technical level of machining metal directly reflects a country's industrial manufacturing strength.

2. Aerospace industry

2.1 Precision requirements for aerospace components

Aerospace equipment has been in extreme working conditions of high temperature, high pressure and high vibration for a long time, and the requirements for machining metals are extremely strict: first, the precision requirements are extremely high, the dimensional tolerance of key components needs to be controlled within 0.001mm, and the surface roughness needs to reach Ra0.025μm; second, strength and lightweight are taken into account, and the weight needs to be reduced while ensuring structural strength to improve the endurance and payload of equipment; third, corrosion resistance and high temperature resistance are excellent, which can resist high-altitude ultraviolet rays, sudden temperature changes and fuel corrosion.

2.2 Commonly used machining metal materials

The aerospace field is very targeted for the selection of materials for machining metals, and the core materials and characteristics are as follows:

| Material type | Core features | Applicable scenarios |

| Titanium Alloy (Ti-6Al-4V) | High strength, low density (4.5g/cm³), excellent corrosion resistance | Aircraft fuselage structural parts, engine blades |

| Superalloy (Inconel 718) | High temperature resistance (can withstand high temperatures above 800°C) and strong oxidation resistance | Aero engine combustion chamber, turbine blades |

| Aluminum Alloy(7075) | The lightweight effect is remarkable, and the processability is good | Aircraft wings, landing gear auxiliary parts |

2.3 Application examples of machined metals in aerospace

When developing the wing structural parts of a large passenger aircraft, an aerospace company chose 7075 aluminum alloy for machining. Through the combination process of "milling roughing + grinding finishing", with five-axis linkage processing equipment, the dimensional tolerance of structural parts is controlled within 0.005mm, and the weight is reduced by 55% compared with traditional steel structural parts. At the same time, the processed aluminum alloy parts are anodized to improve corrosion resistance and ensure their service life in high-altitude and complex environments for more than 20 years. This application not only improves the endurance of passenger aircraft, but also reduces operating costs.

3. Automobile manufacturing

3.1 Strength and durability requirements of automobile components

The core requirements for machined metals include: first, high strength, transmission system and chassis components need to have sufficient tensile strength and yield strength to resist torque and impact; second, high durability, to ensure that there will be no fatigue failure during the service life of more than 100,000 kilometers; Third, it is cost-effective and suitable for large-scale mass production.

3.2 The Role of Machined Metals in Automotive Manufacturing

Machined metal is the core material of automobile manufacturing, covering key parts such as the power system, transmission system, chassis, and body of the automobile. According to statistics, the amount of machining metal used in a traditional fuel vehicle accounts for 60%-70% of the weight of the vehicle, and even for new energy vehicles, this proportion is more than 50%. Its core role is to transform metal materials into parts with specific functions through precise processing technology, ensuring the power output, driving stability and safety of the car.

3.3 Analysis of specific application cases

In the research and development of a new gearbox, an automobile manufacturer chose 40Cr alloy steel to process the gearbox spindle. Through the process route of "turning roughing + milling keyway + grinding finishing", the tensile strength of the spindle is increased to more than 980MPa, and the roundness error is controlled within 0.003mm. At the same time, the processed spindle is subjected to high-frequency quenching treatment to increase the surface hardness to HRC58-62 and enhance wear resistance. After the actual vehicle test, the spindle has no obvious wear and tear within a mileage of 150,000 kilometers, and the transmission efficiency of the gearbox has been increased by 8% and the failure rate has been reduced by 60%. In addition, under the trend of body lightweight, the manufacturer also chose 6061 aluminum alloy to process the engine block, which reduces the weight by 40% and improves fuel economy by 12% compared with the traditional cast iron block.

4. Medical equipment

4.1 Strict standards for materials in medical equipment

Medical equipment is directly related to human health and life safety, and the requirements for machining metals far exceed those of other fields: first, it has excellent biocompatibility, and there is no allergic or toxic reaction after contact with human tissues and body fluids; second, it has strong corrosion resistance, which can resist the erosion of human body fluids and disinfection reagents; third, the precision is extremely high, especially for implantable medical devices, the dimensional tolerance needs to be controlled within 0.001mm; fourth, the surface finish is high to avoid bacterial growth and tissue adhesion.

4.2 Application of machined metal in medical devices

The application of machined metal in the field of medical equipment is mainly divided into two categories: one is implantable medical devices, such as artificial joints, orthopedic screws, heart stents, etc.; The second is the core structural parts of medical diagnosis and treatment equipment, such as CT machines and MRI equipment. Commonly used materials include medical stainless steel (316L), titanium alloy (Ti-6Al-4V ELI), cobalt-chromium alloy, etc., which can perfectly match the stringent requirements of medical equipment through precise machining and surface treatment.

4.3 Successful Cases and Technological Advancements

When a medical device company develops artificial hip joints, it chooses medical titanium alloy (Ti-6Al-4V ELI) as the core material. Through the five-axis linkage grinding technology, the spherical roundness error of the hip joint is controlled within 0.0005mm, and the surface roughness reaches Ra0.01μm. At the same time, plasma spraying is applied to the processed surface to improve biocompatibility and wear resistance. After the artificial hip joint is implanted in the human body, the fusion time with the bone is shortened to 3 months, and the service life is more than 15 years, which is 50% higher than that of the traditional stainless steel hip joint. In addition, with the advancement of 3D printing and machining integration technology, the company has also achieved mass production of personalized artificial joints, which can accurately match the bone size of different patients, and the success rate of surgery has increased by 25%.

5. Conclusion

Summarize the application areas of machining metals

The core application of machined metals in modern industry is concentrated in the three major fields of aerospace, automobile manufacturing, and medical equipment, and its application logic revolves around the core framework of "working condition requirements, material selection, and process optimization": the aerospace field focuses on lightweight and extreme environmental adaptability, giving priority to titanium alloys and superalloys; In the field of automobile manufacturing, it takes into account both strength and cost performance, mainly alloy steel and aluminum alloy; The medical device field focuses on biocompatibility and high precision, and the core is medical stainless steel and titanium alloy. In addition to the above fields, machined metals are also widely used in industries such as electronic equipment, construction machinery, and marine engineering. In the future, with the upgrading of processing technology, machined metals will develop in the direction of more precision, more efficient and more environmentally friendly, further supporting the innovation and upgrading of high-end industries.

【Yigu Technology's Perspective】As a company focusing on precision machining technology, we believe that the core value of machined metals is to "accurately adapt to industrial needs". The application practice of the three core areas shows that the deep integration of materials and processes is the key to enhancing product value. In the future, with the advancement of Industry 4.0, intelligent processing technology will be deeply integrated with machining metal to realize digital control of the whole process from material selection, process planning to finished product testing. Enterprises need to focus on the research and development of high-end material processing technology and intelligent equipment in order to seize the opportunity in high-end fields such as aerospace and medical equipment and promote the high-quality development of modern industry.

FAQ

1. What are the core advantages of using titanium alloy as a machining metal in the aerospace field? There are three core advantages: first, it is lightweight, with a density of only 4.5g/cm³, which is 43% lighter than steel, which can significantly improve the endurance and payload of equipment; second, it has excellent corrosion resistance, which can resist complex high-altitude environments and fuel corrosion; third, it has high strength, with a tensile strength of more than 900MPa, which can meet the strength requirements of extreme working conditions.

2. How do machined metals balance strength and lightweight requirements in automotive manufacturing? It is mainly achieved through material selection and process optimization: high-strength alloy steel (such as 40Cr) is selected for power transmission components to ensure strength; high-strength aluminum alloys (such as 7075) are selected for body, engine and other components to achieve lightweight; At the same time, precise cutting and heat treatment processes are used to reduce material waste while improving strength, taking into account both performance and cost.

3. Why should medical titanium alloys be preferred for machining metals for medical equipment? Because medical titanium alloy has three core advantages: first, it has excellent biocompatibility, no rejection with human tissues, and is suitable for long-term implantation; second, it has strong corrosion resistance, which can resist the erosion of human body fluids and disinfection reagents; third, the strength is close to bone, which can reduce the stress damage to bones after implantation and improve the safety of use.

4. What are the future trends in machined metals in industrial applications? There are three core trends: one is high precision, with dimensional tolerances breaking through to 0.0001mm to meet the needs of high-end equipment; the second is intelligent processing, combining AI and big data to achieve automatic process optimization; and the third is greening, using environmentally friendly cutting fluids and energy-saving processing equipment to reduce environmental impact.