Precision Plastic Injection Molding produces components with extremely tight tolerances, superior surface finishes, and exceptional consistency—often for millions of cycles. At the heart of this process lies the mold, and its longevity is dictated by the wear-resistant die steel from which it's crafted. Choosing the wrong steel can lead to premature failure, unacceptable part defects, and catastrophic project costs. This guide, crafted for tooling engineers, procurement specialists, and manufacturing managers, will navigate the critical selection criteria for die steel, from understanding the unique wear mechanisms in precision molds to comparing material grades and validating performance. We’ll transform this complex material science decision into a clear, actionable strategy for your most demanding projects.

What Is Precision Plastic Injection Molding?

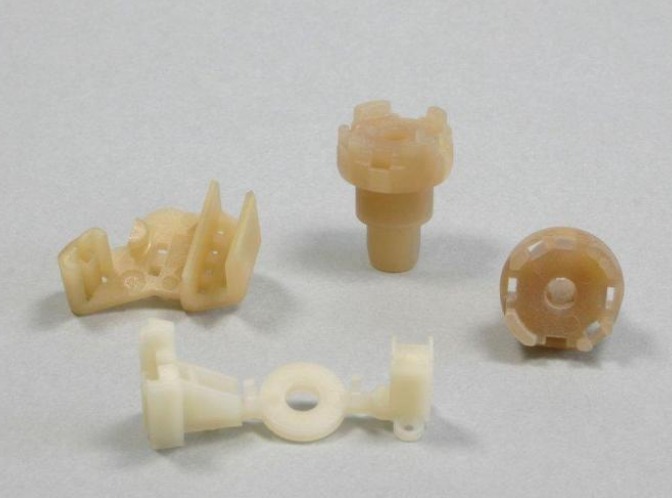

Precision Plastic Injection Molding is a high-stakes manufacturing process defined by its exacting requirements. It goes beyond simply filling a cavity to produce parts that meet micron-level tolerances (often ±0.001" or tighter), possess optical or medical-grade surface finishes, and are produced with absolute repeatability across high volumes—frequently exceeding one million shots. This discipline is essential for producing medical devices (implants, diagnostics), optical lenses, micro-electronics connectors, and automotive sensors. The process demands extraordinary stability from the mold, which must resist dimensional change, surface degradation, and corrosive attack over its entire lifespan. The steel is the foundation upon which this precision is built.

How Do Wear Conditions Differ in Precision Molds?

Wear in a high-cavitation precision mold is not a single phenomenon but a combination of aggressive, simultaneous attacks that degrade critical surfaces.

- Abrasive Wear: This is the primary wear mechanism. It is caused by filled polymers, which contain glass fibers, minerals (talc, calcium carbonate), or flame retardants. These hard particles act like sandpaper, microscopically scouring and eroding the steel surface at gates, along flow paths, and on sealing surfaces. A mold running a 40% glass-filled nylon can experience wear rates orders of magnitude higher than one running unfilled polypropylene.

- Adhesive Wear (Gallin g): Under high clamp tonnage and injection pressure, the molten plastic can temporarily "weld" to microscopic high points on the steel surface. As the part is ejected, these welded points are torn away, pulling tiny bits of steel with them. This is common with sticky materials like certain PVCs or ABS and leads to a dull, matte finish on what should be a polished cavity.

- Corrosive Wear: Many engineering plastics, such as PVC, flame-retardant ABS, or POM (acetal), release acidic or corrosive byproducts (hydrochloric acid, formaldehyde) during processing at high temperatures. This chemical attack pits and etches the steel, creating stress concentrators that accelerate crack propagation and ruin surface finish.

Which Properties Define Wear-Resistant Die Steel?

Selecting the optimal steel requires balancing three core properties that are often in tension with one another.

| Property | Why It Matters for Precision Molds | How It's Achieved |

|---|---|---|

| Abrasion Resistance | Directly counteracts the cutting action of filled plastics. Preserves sharp edges, fine details, and critical dimensions over millions of cycles. | High hardness (HRC) and a high volume of hard, stable carbides (vanadium, molybdenum) in the steel matrix. |

| Toughness | Resistance to chipping and cracking, especially in thin ribs, sharp corners, and intricate core pins. Lack of toughness leads to catastrophic failure. | A balanced chemistry and a precise heat treatment that produces a fine, tempered martensitic structure without excessive retained austenite. |

| Polishability & Texture Retention | The ability to achieve a mirror finish (SPI A1) and hold fine textures without "washing out." Essential for optical and cosmetic parts. | A very clean, homogeneous steel with a fine, uniform grain structure and minimal non-metallic inclusions (sulfides, oxides). |

The Engineering Triangle: You cannot maximize all three simultaneously. A steel hardened to HRC 62 for maximum abrasion resistance will be more brittle. A very tough steel at HRC 48 may not resist abrasion sufficiently. The art of selection lies in finding the grade and heat treatment that provides the optimal compromise for your specific polymer, part geometry, and required mold life.

How Do AISI H13, H11, and Premium Stainless Grades Compare?

The following table compares the most common wear-resistant die steels for precision applications, highlighting their key differentiators.

| Steel Grade (AISI) | Primary Alloying Elements | Typical Hardness Range | Key Strengths | Best Application Fit |

|---|---|---|---|---|

| H13 (1.2344) | Cr, Mo, V (Hot Work) | 48 - 52 HRC | Excellent balance of toughness and thermal fatigue resistance. Good polishability. The industry standard for high-volume engineering plastics. | High-cavitation molds for glass-filled nylons, PBT, POM. Cores and cavities subject to thermal cycling. |

| H11 (1.2343) | Cr, Mo, V (Similar to H13) | 46 - 50 HRC | Slightly higher toughness than H13, with good machinability in the annealed state. | Applications where impact resistance is critical over extreme hardness, or for very intricate, delicate core features. |

| 420 Stainless (1.2083) | Cr (Martensitic Stainless) | 48 - 52 HRC (Hardened) | Superior corrosion resistance and very good polishability. Good wear resistance. | Molds for corrosive plastics (PVC, flame-retardant materials), medical-grade polymers, and applications requiring a perfect optical finish. |

| Premium Stainless (e.g., Stavax ESR) | Cr, Mo, V, with ESR refinement | 52 - 56 HRC | Exceptional cleanliness (ESR process), allowing for supreme mirror polish. Combined good wear and corrosion resistance. | Optical lenses, light guides, cosmetic components, and high-end medical devices where surface perfection is paramount. |

What Role Does Hardness Play in Abrasion Resistance?

Hardness, measured on the Rockwell C scale (HRC), is the primary but not sole indicator of abrasion resistance. The relationship is direct: a higher HRC generally provides better resistance to scratching and cutting by abrasive fillers.

- The Trade-off: Pushing hardness above approximately 52 HRC for H13 or 54 HRC for premium stainless steels begins to significantly reduce toughness. A core pin at HRC 58 might resist wear brilliantly but is at high risk of snapping under the cyclic stress of injection pressure.

- Application-Specific Targets:

- General Engineering Plastics (unfilled): HRC 48-50 provides an excellent balance.

- Moderately Abrasive Materials (20-30% glass fill): Target HRC 50-52.

- Highly Abrasive Materials (40%+ glass/mineral fill): Target HRC 52-54, but only in steels specifically formulated for high hardness (like premium grades) and in robust mold sections.

How Do Heat-Treatment Routes Affect Toughness and Distortion?

The specified steel grade provides the potential; the heat treatment determines the final reality of its properties. For precision molds, controlling distortion is as critical as achieving hardness.

- Pre-heating & Austenitizing: Slow, controlled heating to the austenitizing temperature is crucial to prevent thermal stress and distortion. The soak time must be sufficient to dissolve carbides fully.

- Quenching: Rapid cooling (in vacuum, gas, or oil) transforms the structure to martensite. High-pressure gas quenching (HPGQ) in a vacuum furnace offers the most uniform cooling, minimizing distortion and internal stress compared to oil quenching.

- Tempering: The quenched steel is too brittle. Tempering (typically double or triple tempering) reheats it to a specific temperature (e.g., 1020°F / 550°C for H13) to impart toughness and relieve stresses. The final hardness is set by this tempering temperature.

- Cryogenic Treatment: An optional step between quenching and tempering, where the steel is cooled to -120°C or lower. This converts retained austenite (a soft, unstable phase) into martensite, which is then tempered. This increases dimensional stability, wear resistance, and can add 1-2 points of HRC.

What Surface Engineering Options Enhance Durability?

Beyond bulk steel properties, surface engineering can dramatically extend mold life, often at a fraction of the cost of a new mold insert.

| Technology | Process Description | Key Benefit | Ideal Use Case |

|---|---|---|---|

| Nitriding (Gas or Plasma) | Diffuses nitrogen into the steel surface, creating an extremely hard (up to 70 HRC) but thin (0.1-0.2mm) compound layer. | Excellent scuffing and adhesive wear resistance. Low processing temperature minimizes distortion. | Cores, cavities, and sliding components (e.g., lifters) in molds for unfilled but sticky plastics. |

| Physical Vapor Deposition (PVD) | A thin (1-5 micron), ultra-hard ceramic coating (TiN, TiAlN, CrN) is vapor-deposited onto the polished surface. | Exceptional abrasion and corrosion resistance with minimal effect on part appearance. Low friction. | High-wear areas in molds for severely abrasive filled materials. Also excellent for corrosion protection. |

| Electroless Nickel (Ni-P) | A uniform, semi-hard (45-50 HRC) nickel-phosphorus alloy is deposited via chemical reaction. | Good corrosion resistance and uniform coverage, even on complex geometries. Provides a release layer. | Molds for corrosive plastics where a PVD coating is not suitable. Often used as an undercoat for other treatments. |

Case in Point: A mold producing a connector from 35% glass-filled PBT was experiencing excessive wear on the gate and the tips of 0.8mm core pins after 200,000 shots. Re-machining the inserts from H13 steel at HRC 52 provided only a marginal improvement. Applying a TiAlN PVD coating to these critical areas increased the service life to over 1.5 million shots before any measurable wear was observed, validating the cost-effectiveness of surface enhancement.

How Can You Test and Validate Steel Performance?

Before committing to full-scale production tooling, several validation steps can de-risk the material selection.

- Pin-on-Disc Wear Testing: A laboratory test where a steel sample (pin) slides against a rotating disc (often the plastic or an abrasive counterpart) under controlled load. It quantifies wear rate and coefficient of friction, allowing for a direct comparison of different steel grades or surface treatments.

- Pilot Mold or "Test" Inserts: For a critical, high-volume project, fabricating a single-cavity mold or a set of test inserts from the candidate steel is the gold standard. The inserts are run in production conditions, and their wear, polish retention, and tendency to corrode are monitored over a defined number of cycles (e.g., 100,000 shots).

- Material Certification & Microcleanliness Analysis: Always require a material certificate from the steel mill. For premium grades (e.g., Stavax ESR), also request a microcleanliness report that quantifies non-metallic inclusions using standards like ASTM E45. This data objectively confirms the steel's suitability for high-polish applications.

Case Studies: High-Cavitation Medical and Optical Molds

Medical: 64-Cavity Microfluidic Diagnostic Cartridge Mold

A manufacturer needed to produce billions of disposable test cartridges from cyclic olefin copolymer (COC). The mold featured hundreds of micro-features and channels with sub-0.1mm dimensions. AISI 420 Stainless Steel was selected for its corrosion resistance against any biological residues and its excellent polishability to ensure clean part ejection and fluidic function. The steel was hardened to 50 HRC via vacuum heat treatment with HPGQ to prevent distortion of the delicate features. To combat wear from the abrasive polymer, all flow channels received a CrN PVD coating. This combination delivered a mold capable of producing tens of millions of defect-free parts.

Optical: 8-Cavity Automotive LED Lens Mold

The project required producing polycarbonate (PC) lenses with a flawless, Class-A optical surface and holding tight focal length tolerances. Premium ESR Stainless Steel (Stavax) was the only choice due to its superior microcleanliness, which is essential for achieving a SPI A1 mirror polish without pits or streaks. The steel was hardened to 54 HRC to maintain the perfect surface finish against the mildly abrasive PC over millions of cycles. The mold was subjected to cryogenic treatment after quenching to ensure maximum dimensional stability, preventing any drift in the critical optical curvature throughout its life.

Conclusion

Selecting wear-resistant die steel for Precision Plastic Injection Molding is a fundamental engineering decision with profound implications for part quality, tooling cost, and production efficiency. There is no universal "best" steel; the optimal choice emerges from a careful analysis of the polymer's abrasiveness and corrosiveness, the required part surface finish, the mold's geometric complexity, and the target production volume. By understanding the trade-offs between hardness, toughness, and polishability—and by leveraging advanced heat treatment and surface engineering—you can specify a steel solution that provides the durability, precision, and reliability your most demanding applications require. This strategic approach transforms the mold base from a consumable into a durable, high-performance asset.

FAQ

Is a higher hardness (HRC) always better for wear resistance?

Not always. While hardness strongly correlates with abrasion resistance, excessive hardness (above ~54 HRC for many grades) drastically reduces toughness, making the steel brittle and prone to chipping or catastrophic cracking. The goal is to select the highest hardness that still provides sufficient toughness for the mold's geometry and operating stresses.

What is the difference between through-hardening and case-hardening steels for molds?

Through-hardening steels (like H13, 420SS) are heat-treated to achieve a uniform hardness throughout the entire cross-section. They are standard for mold cavities and cores. Case-hardening steels (like P20, which is often carburized) have a hard, wear-resistant surface over a softer, tougher core. They are less common in high-precision molds but may be used for large, bulky mold bases where deep toughness is needed.

How does the "cleanliness" of steel affect a precision mold?

Steel cleanliness refers to the amount and size of non-metallic inclusions (sulfides, oxides) within the alloy. In a polished cavity, these inclusions appear as pits or streaks, ruining an optical finish. During polishing, they can tear out, creating voids. For high-gloss or textured surfaces, specifying ESR (Electro-Slag Remelted) or VAR (Vacuum Arc Remelted) premium grades is essential, as these processes dramatically reduce inclusion content.

Can you weld or repair a hardened, wear-resistant mold steel?

Yes, but it requires expertise. Tool steel welding must be performed with the correct filler rod and a meticulous pre-heat/post-heat protocol to match the base metal's properties and prevent cracking. For critical surfaces, the repair area will need to be re-machined, heat-treated, and re-polished. It is always a specialized and costly process.

When should I consider using a tool steel with higher vanadium content?

Vanadium forms very hard, stable vanadium carbides (VC). Steels with higher vanadium content (e.g., some premium "super wear" grades) offer superior abrasion resistance against the most aggressive filled plastics (e.g., long glass fibers, high mineral content). However, these steels can be more challenging to machine and polish. They are justified when abrasive wear is the primary failure mode and mold life with standard steels is unacceptably short.

Contact Yigu Technology for Custom Manufacturing.

At Yigu Technology, we understand that the foundation of successful Precision Plastic Injection Molding is expert tooling. Our engineering team possesses deep material science knowledge to guide you in selecting the optimal wear-resistant die steel for your specific polymer, volume, and quality requirements. We partner with premium steel mills and employ advanced heat treatment and surface engineering processes to maximize mold performance and longevity. From complex medical devices to high-volume automotive components, we build tooling that is an asset, not a liability. Contact Yigu Technology today to discuss your next precision molding project and leverage our expertise in durable, high-performance mold making.