Injection molding products are the ubiquitous, precision-formed plastic and metal parts that define our modern world. From the intricate housing of your smartphone to the robust components under your car's hood, this manufacturing process is the engine behind mass-produced, high-quality items. This ultimate guide is designed for product designers, engineers, entrepreneurs, and procurement specialists. We will demystify the process, explore its vast potential and limitations, and provide the practical knowledge needed to navigate the journey from concept to mass-produced part, ensuring you can make informed decisions for your next project.

What Is Injection Molding?

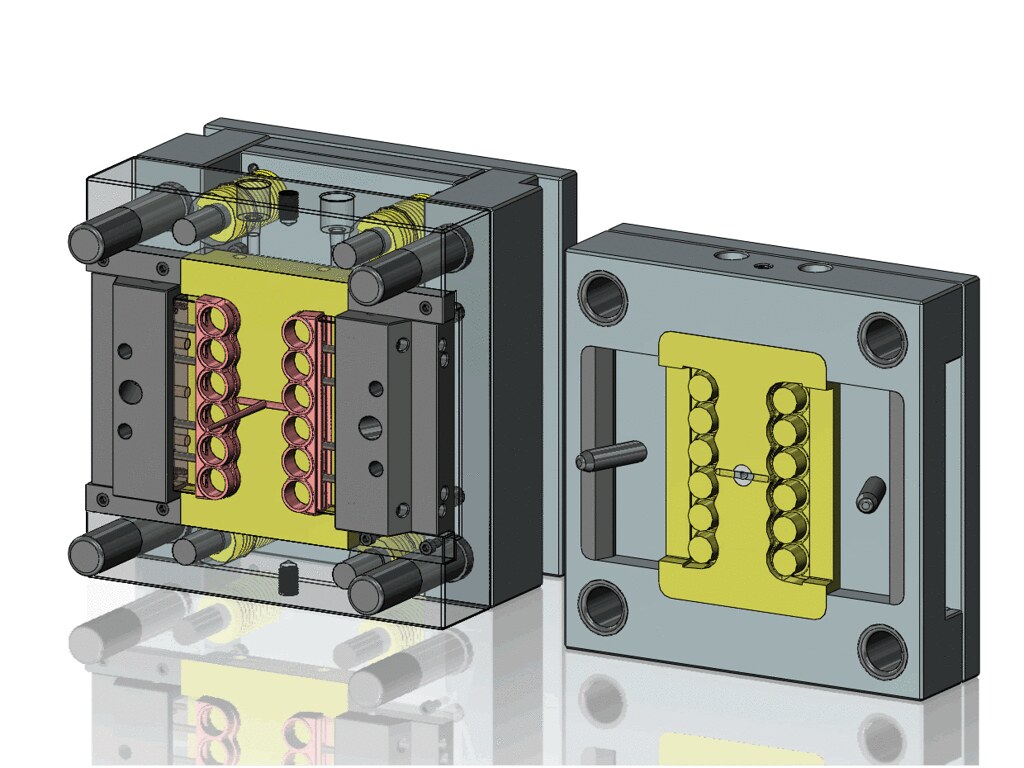

Injection molding is a high-volume manufacturing process where molten material—most commonly thermoplastic polymers—is injected under high pressure into a precision-engineered metal mold cavity. The material cools and solidifies, taking the shape of the cavity, and is then ejected as a finished part. This process is renowned for its ability to produce complex geometries with exceptional repeatability, tight tolerances, and excellent surface finishes.

The fundamental output—injection molding products—are characterized by their high structural integrity, excellent detail replication, and the presence of subtle features like parting lines, ejector pin marks, and gate vestige, which are hallmarks of the process.

How Does the Injection Molding Process Work?

The injection molding cycle is a precisely choreographed sequence of events, typically fully automated. Understanding this workflow is key to designing for manufacturability.

- Clamping: The two halves of the injection mold are securely closed and held together by a powerful clamping unit. Tonnage (clamp force) must be sufficient to resist the immense injection pressure.

- Injection: Plastic pellets are fed from a hopper into a heated barrel. A reciprocating screw mixes and melts the material into a homogeneous melt. This molten plastic is then injected at high speed and pressure into the closed mold cavity.

- Cooling: The molten plastic inside the mold begins to cool and solidify. Cooling time is often the longest phase of the cycle and is critical for preventing defects like warpage and ensuring dimensional stability. Efficient cooling is achieved through a network of channels circulating water or oil.

- Plasticizing: While the current shot is cooling, the screw retracts, drawing in the next batch of material to be melted for the subsequent cycle.

- Ejection: After sufficient cooling, the mold opens, and ejector pins push the solidified part out of the mold cavity. The mold then closes, and the cycle repeats.

Professional Insight: A common pitfall is underestimating cooling time. For a simple, thin-walled part, cooling might be 5-10 seconds. For a thick, chunky component, it could exceed 60 seconds. Rushing this phase to increase output per hour is a false economy, as it leads to high scrap rates and dimensional inaccuracies. A seasoned manufacturer will optimize the cooling channel layout and cycle time based on thermodynamic simulations to find the perfect balance between quality and productivity.

Types of Injection Molding Products

The versatility of injection molding allows for a staggering variety of product types, often defined by the process variation used.

- Consumer Products: High-volume, often aesthetically critical items like tool housings, kitware, toys, and consumer electronics enclosures. Surface finishes range from textured to high-gloss polish.

- Technical Components: Parts where function dominates, such as gears, bushings, connectors, and medical device components. These require precise tolerances and specific material properties.

- Overmolded Products: Combines a rigid substrate (often metal or another plastic) with a thermoplastic elastomer (TPE) overmold to create soft-grip surfaces on tools, toothbrush handles, or multi-material seals.

- Insert Molding: Metal inserts (threaded bosses, electrical contacts) are placed into the mold, and plastic is injected around them, creating a strong, integrated assembly in one shot.

- Micro-Injection Molding: Produces extremely tiny, high-precision parts weighing less than a gram, used in medical (catheter components) and micro-optics. It requires specialized machines and micron-level mold tolerances.

Which Materials Are Most Suitable?

Material selection is the single most critical decision affecting a product's performance, cost, and manufacturability. The most common categories are thermoplastics, which can be re-melted and re-formed.

| Material Family | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Commodity Thermoplastics | Polypropylene (PP), Polyethylene (PE), Polystyrene (PS) | Low cost, good processability, decent chemical resistance. | Packaging, disposable labware, low-stress containers. |

| Engineering Thermoplastics | Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), Nylon (PA) | Enhanced strength, heat resistance, toughness, and dimensional stability. | Automotive parts, electronic housings, power tools, consumer appliances. |

| High-Performance Thermoplastics | PEEK, PPS, PEI (Ultem) | Exceptional thermal stability, chemical resistance, and mechanical strength. | Aerospace, medical implants (sterilizable), semiconductor equipment. |

| Thermoplastic Elastomers (TPEs) | TPS, TPU, TPV | Rubber-like flexibility and elasticity, combined with plastic processability. | Seals, gaskets, soft-touch overmolds, wearable device straps. |

Material Science Note: When selecting a material, engineers must cross-reference data sheets for key properties: Melt Flow Index (MFI) for processability, tensile strength, impact resistance, heat deflection temperature (HDT), and UL94 flammability rating. For instance, a children's toy may prioritize impact-resistant ABS with a high UL94 HB rating, while an under-hood automotive sensor requires glass-filled nylon (PA66 GF30) for its high HDT and resistance to oils and fuels.

What Are the Key Advantages and Limitations?

A balanced view is essential for project feasibility.

Advantages:

- High Efficiency & Scalability: Once the mold is validated, per-unit costs plummet, making it unbeatable for high-volume production (thousands to millions of parts). Cycle times can be seconds.

- Unmatched Repeatability: Every shot produces an identical part, ensuring consistent quality and performance across the entire production run.

- Design Complexity: Can produce intricate geometries, undercuts (with side-actions), threads, and living hinges in a single operation, reducing assembly steps.

- Excellent Surface Finish: Molds can be polished, textured, or engraved, transferring that finish directly to the part, often eliminating secondary finishing.

Limitations:

- High Initial Investment: Injection mold tooling is complex and expensive, often ranging from $5,000 for a simple aluminum mold to $100,000+ for a multi-cavity, hardened steel production tool. This is a barrier to low-volume production.

- Lead Time for Tooling: Designing, machining, and qualifying a mold can take 8-16 weeks, delaying time-to-market.

- Design Restrictions: Parts must be designed for demolding (draft angles are mandatory). Very thick wall sections can lead to sinks and voids, while extremely thin walls may not fill properly.

Applications Across Industries

The application of injection molding products is a testament to the process's adaptability.

- Automotive: From interior trim panels and dashboard components to under-hood fluid reservoirs and complex lighting assemblies. The trend towards lightweighting drives the use of engineered plastics to replace metal.

- Medical: Single-use, disposable products like syringes, IV connectors, and specimen containers are ideal for injection molding due to sterility and cost-effectiveness. High-precision surgical instruments and diagnostic device housings also rely on it.

- Consumer Electronics: The sleek, seamless housings for smartphones, laptops, and wearables are masterclasses in injection molding, requiring ultra-high gloss finishes, tight tolerances for fit, and often multi-material molding for antenna integration.

- Packaging: Virtually all thin-walled plastic containers, caps, and closures are injection molded. The industry demands incredibly fast cycle times and absolute consistency.

- Industrial & Consumer Goods: This vast category includes everything from power tool bodies and garden equipment to storage bins and furniture components.

How Is Quality Controlled?

Quality in injection molding is engineered into the process, not inspected in at the end.

- Scientific Molding: This is the gold standard. It involves establishing and meticulously controlling the four critical plastic variables: Pressure, Temperature, Time, and Distance. A process is developed using a DOE (Design of Experiments) approach and locked in, making it repeatable on any machine.

- First Article Inspection (FAI): A comprehensive dimensional and functional check of the first parts from a production mold, often using a Coordinate Measuring Machine (CMM), to validate the tool and process.

- Statistical Process Control (SPC): Key parameters (part weight, critical dimensions) are measured at regular intervals and plotted on control charts. This provides real-time data to identify and correct process drift before it produces rejects.

- Mold Maintenance & Management: Regular, scheduled maintenance of the injection mold—cleaning, lubrication, and inspection for wear—is non-negotiable for maintaining part quality over the tool's lifespan, which can be millions of cycles.

How to Choose the Right Manufacturer?

Selecting a partner is as critical as designing the part itself. Look beyond price per piece.

- Evaluate Engineering Support: Do they offer Design for Manufacturability (DFM) analysis upfront? A good partner will proactively suggest design changes to reduce cost, improve strength, and ensure reliable molding.

- Assess Technological Capability: Do they have the press tonnage, shot size, and auxiliary equipment (robots, hot runner controllers) for your part? Can they handle the required materials (e.g., high-temperature plastics)?

- Scrutinize Quality Systems: Ask about their process validation (Scientific Molding), inspection equipment, and quality certifications (e.g., ISO 9001, ISO 13485 for medical).

- Review Their Portfolio & Experience: Have they produced similar parts for your industry? Ask for case studies or references.

- Clarify Communication & Project Management: Who is your point of contact? How are progress updates, issues, and engineering changes communicated? Transparency is key.

Case Study: A startup developing a novel water filtration device needed a complex, leak-proof housing. Their initial design had sharp corners and uneven wall thickness. The chosen manufacturer's engineering team provided a detailed DFM report, suggesting uniform wall thickness, adding radii to all internal corners to reduce stress, and recommending a specific grade of glass-filled polypropylene for chemical resistance and stiffness. This collaboration before tool cutting prevented costly mold modifications and part failures, saving the project an estimated $15,000 and 6 weeks of delay.

Conclusion

Injection molding is a powerful, indispensable manufacturing process for creating high-volume, precision plastic parts and products. Success hinges on a symbiotic relationship between intelligent part design, astute material selection, and partnership with a capable, communicative manufacturer. By understanding the process's core principles, advantages, and constraints outlined in this guide, you are equipped to leverage injection molding effectively, transforming innovative ideas into reliable, market-ready products that can be manufactured at scale with consistent quality.

FAQ

What is the minimum order quantity (MOQ) for injection molding products?

MOQs are primarily driven by the high cost of tooling. For a standard production run, manufacturers typically require an MOQ of 10,000 to 50,000 units to amortize the mold cost. However, for prototyping or low-volume production, options like aluminum prototype molds (good for ~1,000-5,000 parts) or using multi-cavity family molds can significantly lower the entry barrier.

How long does it take to make an injection mold?

Lead time varies dramatically with complexity. A simple, single-cavity aluminum mold might take 4-6 weeks. A complex, multi-cavity hardened steel production mold with exotic materials and intricate cooling can take 14-20 weeks or more. This includes design, material procurement, CNC machining, EDM (Electrical Discharge Machining), polishing, assembly, and sampling.

What is the difference between a hot runner and a cold runner mold system?

A cold runner system has channels that solidify with each shot and are ejected as waste (sprues and runners). A hot runner system uses heated manifolds and nozzles to keep the plastic molten in the channels, injecting directly into the part. Hot runners eliminate waste, reduce cycle time, and allow for better pressure control but are more expensive and complex to maintain.

Can injection molding be used with sustainable or recycled materials?

Yes, this is a major industry trend. Many engineering-grade recycled resins (rPP, rABS) and bio-based polymers (PLA, PHA) are compatible with injection molding. However, they often require process adjustments due to different melt viscosities and thermal stability. Discuss sustainability goals with your manufacturer early in the design phase.

What are common defects in injection molded parts and how are they fixed?

Common defects include:

- Sink Marks: Caused by insufficient cooling/packing in thick sections. Fix by redesigning for uniform wall thickness or increasing pack/hold pressure.

- Warpage: Uneven cooling causes part distortion. Fix by optimizing cooling channel layout and ensuring symmetrical cooling.

- Short Shot: The mold doesn't fill completely. Fix by increasing melt temperature, injection speed, or pressure.

- Flash: Excess plastic leaks out of the mold cavity. Fix by increasing clamp force, reducing injection pressure, or repairing worn mold seals.

Contact Yigu Technology for Custom Manufacturing.

Ready to turn your product vision into a high-quality, mass-producible reality? At Yigu Technology, we specialize in end-to-end custom injection molding solutions. From initial DFM consultation and precision mold making to full-scale production and assembly, our team of engineers leverages state-of-the-art technology and rigorous scientific molding principles to ensure your project's success. We work with a wide range of materials, including sustainable options, and serve industries from medical to consumer electronics. Contact us today for a collaborative quote and see how we can bring efficiency, quality, and value to your next project.