What is Reverse Injection Molding?

Reverse Injection Molding is a specialized manufacturing process that stands in contrast to traditional injection molding. In traditional injection molding, the molten material is injected into a mold cavity, which is then cooled to solidify the part. This is a widely used method for mass - producing plastic parts with a high degree of precision and consistency.

However, in Reverse Injection Molding, the process is essentially reversed. Instead of injecting the molten material into a closed mold cavity, the mold is first filled with a liquid or semi - liquid medium. Then, the molten plastic (or other material) is injected into this medium. As the plastic cools and solidifies, it takes on the shape defined by the interaction between the plastic and the medium.

Here is a simple comparison table to illustrate the key differences:

| Aspect | Traditional Injection Molding | Reverse Injection Molding |

| Mold Filling Sequence | Molten material first into a closed mold cavity | Liquid/semi - liquid medium fills the mold first, then molten material is injected |

| Cooling Process | Molten material cools in a static mold cavity | Molten material cools while interacting with the pre - filled medium |

| Complexity of Part Geometry | Well - suited for complex geometries with proper mold design | Can create unique geometries that are difficult to achieve with traditional methods due to the interaction with the medium |

For example, imagine creating a part with internal channels or complex hollow structures. In traditional injection molding, this might require intricate core - pulling mechanisms or multi - piece molds. With Reverse Injection Molding, the liquid medium can be designed to flow in a way that naturally creates these internal features as the plastic is injected and solidifies around it. This can potentially simplify the mold design and manufacturing process for certain types of parts.

The Working Process in Detail

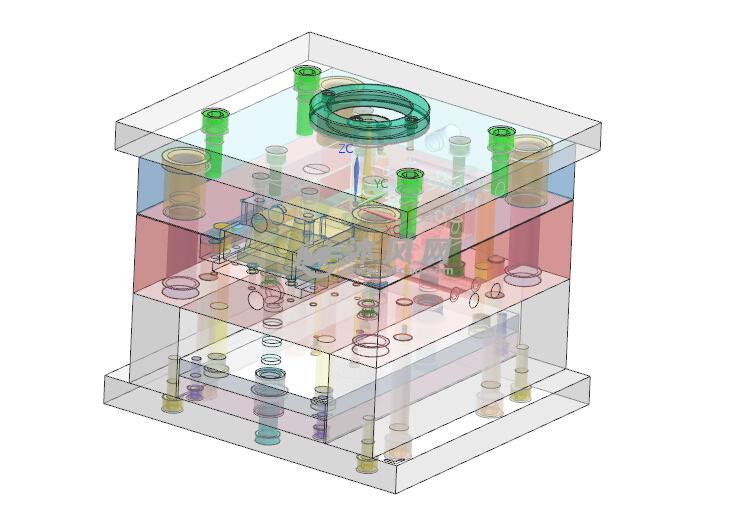

1. Mold Preparation

- Inspection and Cleaning: Before starting the reverse injection molding process, the mold needs to be thoroughly inspected. Check for any signs of wear, damage, or residue from previous production runs. A damaged mold can lead to inconsistent part quality or even production failures. Use appropriate cleaning agents and tools to remove any dirt, grease, or solid particles from the mold surfaces. For example, a mild detergent solution can be used for general cleaning, and a soft - bristled brush can be employed to clean intricate mold cavities without scratching the surface.

- Coating Application (Optional): In some cases, a release agent or a special coating may be applied to the mold surface. This helps in the easy removal of the finished part after the molding process. The release agent should be applied evenly and in the correct amount. Too little may cause the part to stick to the mold, while too much can affect the surface finish of the part.

2. Medium Filling

- Selecting the Right Medium: The choice of the liquid or semi - liquid medium is crucial. It should have the right viscosity, density, and chemical compatibility with the molten plastic to be injected later. For instance, if creating a part with a specific internal structure, a medium that can flow and displace in a predictable way is required. Some common media include water - based solutions, certain types of gels, or low - viscosity polymers.

- Filling Operation: Using a precise filling system, the medium is carefully introduced into the mold cavity. The filling speed and pressure need to be controlled accurately. If the filling speed is too fast, it may cause air bubbles to be trapped in the medium, which can later affect the quality of the final part. On the other hand, if the speed is too slow, it may lead to an uneven filling of the mold. The filling pressure should be adjusted according to the mold size, the viscosity of the medium, and the complexity of the cavity.

3. Material Injection

- Melting and Preparing the Plastic: The plastic material (or other material) is first heated to its melting point in an injection unit. The temperature must be carefully monitored and controlled. Different plastics have different melting ranges. For example, polyethylene has a melting point in the range of 110 - 130°C, while polycarbonate melts at around 220 - 260°C. Heating the plastic to the wrong temperature can result in issues such as poor flowability, over - degradation of the material, or inconsistent part quality.

- Injecting into the Medium: Once the plastic is molten, it is injected into the pre - filled mold containing the medium. The injection pressure and speed are key parameters. High injection pressure can ensure that the plastic penetrates and displaces the medium effectively, but it may also cause excessive stress on the mold and the part. The injection speed should be coordinated with the viscosity of the plastic and the behavior of the medium. For example, a more viscous medium may require a higher injection speed to achieve the desired displacement and part formation.

4. Cooling and Solidification

- Cooling System Activation: After injection, the cooling process begins. A cooling system, usually involving channels within the mold through which a coolant (such as water or a special cooling fluid) flows, is activated. The temperature of the coolant and the flow rate are adjusted to control the cooling rate of the plastic. A too - rapid cooling rate can cause internal stresses in the part, leading to warping or cracking, while a too - slow cooling rate can increase the production cycle time.

- Monitoring Solidification: The solidification process of the plastic is monitored. This can be done through various means, such as temperature sensors embedded in the mold or by observing the pressure changes during the cooling phase. As the plastic solidifies, it takes on the shape defined by the interaction with the medium, creating the final part geometry. The time required for solidification depends on factors like the type of plastic, the part thickness, and the cooling conditions. Thicker parts generally require longer cooling times. For example, a part with a thickness of 5 mm may take 30 - 60 seconds to solidify under normal cooling conditions, while a thinner part of 1 mm may solidify in 10 - 20 seconds.

Materials and Their Selection

1. Suitable Plastics

- Polypropylene (PP): PP is a popular choice for reverse injection molding due to its relatively low cost, good chemical resistance, and high heat resistance. It has a melting point in the range of 160 - 165°C for homopolymer types. PP can withstand various chemicals, making it suitable for parts that will come into contact with different substances. For example, in the production of chemical storage containers with complex internal structures created by reverse injection molding, PP's chemical resistance ensures the container's integrity over time. It also has a relatively low density, which is beneficial when weight is a concern.

- Polycarbonate (PC): PC offers excellent impact resistance, high - temperature resistance (it can withstand temperatures from - 40 to 130°C), and good dimensional stability. Its transparency makes it ideal for applications where visibility is required, such as in optical components or clear enclosures. In reverse injection molding, PC can be used to create parts with intricate shapes and high - precision requirements. For instance, in the manufacturing of automotive headlight lenses with complex internal light - diffusing structures, PC's properties allow for the creation of a durable and optically - efficient product.

- Acrylonitrile Butadiene Styrene (ABS): ABS is known for its good impact resistance, dimensional stability, and ease of processing. It has a relatively wide processing temperature range, which makes it easier to work with in the reverse injection molding process. ABS is often used in consumer electronics, automotive interiors, and toys. In reverse injection molding, it can be used to create parts with unique geometries. For example, the internal structural components of a high - end smartphone case, which need to provide both protection and a specific form factor, can be made from ABS through reverse injection molding.

2. Metals (for Metal - Plastic Composites)

- Aluminum: Aluminum is a lightweight metal with good strength - to - weight ratio. When used in combination with plastics in reverse injection molding for metal - plastic composites, it can add strength and rigidity to the final product. For example, in the manufacturing of some high - end automotive parts or aerospace components, aluminum inserts are used in reverse injection molding with plastic. The aluminum provides the necessary mechanical strength, while the plastic offers corrosion resistance and can be shaped into complex forms more easily. Aluminum also has good thermal conductivity, which can be beneficial in applications where heat dissipation is required.

- Copper: Copper has excellent electrical and thermal conductivity. In reverse injection molding for applications such as electronic components or heat sinks, copper can be used in combination with plastic. For instance, in the production of a heat sink for a high - power electronic device, copper can be the core material to efficiently conduct heat away, and the plastic can be molded around it to provide insulation and a specific form factor. However, copper is relatively heavy compared to aluminum, so its use needs to be carefully considered based on the application requirements.

3. Considerations for Material Selection

- Compatibility with the Medium: The material (plastic or metal) must be compatible with the liquid or semi - liquid medium used in the reverse injection molding process. Chemical reactions between the material and the medium can lead to poor part quality, such as discoloration, brittleness, or reduced mechanical properties. For example, if a water - based medium is used, the plastic should not be water - soluble or react with water.

- Mechanical Properties Requirements: The final part's intended use determines the required mechanical properties of the material. If the part needs to withstand high mechanical stresses, a material with high tensile strength and impact resistance, like PC or a high - strength grade of PP, should be chosen. On the other hand, if flexibility is required, a different material or a modified version of a base material might be more suitable.

- Cost - effectiveness: Material cost is a significant factor, especially for large - scale production. While high - performance materials like PC may be ideal for certain applications, their higher cost may make them unsuitable for cost - sensitive products. In such cases, more cost - effective alternatives like PP or ABS may be considered, provided they meet the minimum performance requirements.

Yigu Technology's Insights

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values Reverse Injection Molding. This innovative process offers distinct advantages in producing complex - shaped and high - performance products.

One of the key strengths lies in its ability to create unique internal structures easily. For example, when manufacturing plastic - metal composite parts, the process can precisely control the interaction between the plastic and the metal insert, resulting in stronger bonding and better - integrated products. This not only improves the mechanical properties of the final product but also expands the application scenarios, especially in industries like aerospace and high - end electronics where lightweight yet strong components are crucial.

Moreover, from a cost - efficiency perspective, Reverse Injection Molding can sometimes simplify the production process, reducing the need for complex post - processing operations. This can lead to shorter production cycles and lower overall production costs, which is beneficial for both small - batch and large - scale production. Looking ahead, we believe Reverse Injection Molding will have an even broader application scope as materials science and manufacturing technology continue to advance.

FAQ

What are the main differences between reverse injection molding and traditional injection molding?

The main differences lie in the mold - filling sequence and the cooling process. In traditional injection molding, molten material is injected into a closed mold cavity first, while in reverse injection molding, a liquid or semi - liquid medium fills the mold first, followed by the injection of molten material. During cooling, in traditional molding, the material cools in a static mold cavity, and in reverse injection molding, it cools while interacting with the pre - filled medium. Reverse injection molding can create unique geometries that are often more challenging to achieve with traditional methods.

How to choose the right materials for reverse injection molding?

When choosing materials, consider their compatibility with the medium used in the process. The material should not react chemically with the medium. Also, think about the mechanical properties requirements of the final product. For high - stress applications, choose materials with high tensile strength and impact resistance. Cost - effectiveness is another factor. High - performance materials may be expensive, so for cost - sensitive products, more affordable alternatives like PP or ABS can be considered if they meet the basic performance needs.

What should be paid attention to during the operation of reverse injection molding equipment?

Safety is crucial. Operators should wear appropriate protective gear, such as safety glasses and heat - resistant gloves. Regarding equipment parameters, carefully control the temperature of the heating unit to ensure the plastic is melted to the correct state. Monitor and adjust the injection pressure and speed according to the material and the mold design. For the cooling system, set the coolant temperature and flow rate properly to ensure the plastic solidifies evenly and without internal stresses. Regularly maintain the equipment, checking for any signs of wear or damage to prevent production failures.