Understanding 2 Plate Injection Moulding Basics

Two - plate injection moulding, a fundamental process in the manufacturing industry, is a method where molten plastic is injected into a two - part mold. This process is highly prevalent due to its simplicity and cost - effectiveness for a wide range of applications.

The Process in a Nutshell

The mold consists of two main parts: the stationary half (also known as the fixed mold plate) and the moving half (the moving mold plate). When the process begins, the mold is closed, creating a cavity that is an exact replica of the desired plastic part. A plastic resin, usually in pellet form, is fed into a heating barrel. Here, it is melted into a viscous liquid state. Then, a reciprocating screw or a plunger exerts high pressure, forcing the molten plastic through a runner system and into the mold cavity. Once the cavity is filled, the plastic is cooled and solidified. Finally, the mold opens, and the now - formed plastic part is ejected.

Its Significance in Manufacturing

Two - plate injection moulding plays a crucial role in various industries. In the automotive industry, it is used to produce interior components such as dashboards, door panels, and various small parts. For example, a typical car may contain hundreds of plastic parts made through this process. In the consumer electronics sector, cases for smartphones, tablets, and laptops are often manufactured using two - plate injection moulding. According to industry reports, over 70% of all plastic products in the consumer goods market are produced through injection moulding processes, with two - plate moulding being one of the most commonly used techniques.

The simplicity of the two - plate mold design also makes it an attractive option for small - to medium - scale production runs. It requires less complex tooling compared to some other injection moulding methods, which reduces the initial investment cost. This makes it accessible for startups and small manufacturing companies looking to produce plastic products efficiently.

The Core Mechanics: How it Works

Mould Structure Breakdown

A two - plate injection mould is composed of several key components.

- Fixed Mold Plate (Stationary Half): This is the part that remains stationary during the injection moulding process. It houses the sprue bushing, which is the channel through which the molten plastic first enters the mould. The fixed mold plate also holds the cavity, which is the negative impression of the final plastic part's outer shape. For instance, when manufacturing a plastic toy car body, the cavity in the fixed mold plate will have the exact shape of the outer shell of the toy car.

- Moving Mold Plate (Moving Half): As the name implies, this part moves during the moulding cycle. It contains the core, which forms the inner part of the plastic product. If we continue with the toy car example, the core in the moving mold plate would create the hollow interior of the car body. Additionally, the moving mold plate is connected to the injection molding machine's moving platen and is responsible for the opening and closing of the mold.

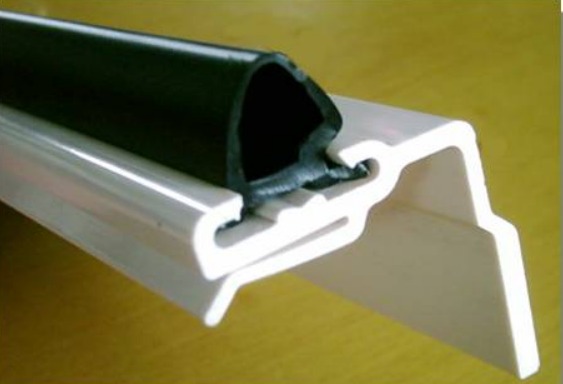

- Guide Pins and Guide Bushings: These components ensure that the moving and fixed mold plates align accurately during the opening and closing of the mold. Guide pins are typically located on one plate, and guide bushings on the other. Their precise fit (usually with a very small clearance, around 0.01 - 0.03 mm in high - precision molds) prevents misalignment, which could lead to defects in the molded parts, such as uneven wall thickness.

- Ejection System: After the plastic part has cooled and solidified, the ejection system comes into play. It consists of components like ejector pins, ejector plates, and return pins. Ejector pins are small rods that push the molded part out of the mold cavity when the mold opens. Ejector plates are used to hold and move the ejector pins, and return pins ensure that the ejection system returns to its original position when the mold closes again.

The Injection Process Step - by - Step

- Plastic Granule Feeding: Plastic granules, which are the raw material, are fed into the hopper of the injection molding machine. These granules can be made from various types of plastics, such as polyethylene (PE), polypropylene (PP), or acrylonitrile - butadiene - styrene (ABS). For example, in the production of plastic storage containers, high - density polyethylene granules are commonly used.

- Heating and Melting: From the hopper, the plastic granules enter a heated barrel. The barrel is equipped with heating elements, usually electric heaters, that raise the temperature of the plastic. The temperature is carefully controlled depending on the type of plastic. For instance, ABS plastic typically melts at around 200 - 250°C. As the granules move through the barrel, they are gradually melted into a viscous, molten state.

- Injection: A reciprocating screw or a plunger inside the barrel is used to generate high pressure. This pressure forces the molten plastic through a runner system. The runner system consists of a main runner (which is connected to the sprue bushing) and smaller secondary runners that distribute the plastic to different parts of the mold cavity. The molten plastic then enters the mold cavity at a high velocity, filling every nook and cranny of the cavity to take the shape of the desired product.

- Cooling: Once the cavity is filled with molten plastic, the cooling process begins. Cooling channels are integrated into the mold plates. These channels carry a coolant, usually water, which absorbs the heat from the molten plastic. As the plastic cools, it solidifies, gradually taking on the shape of the mold cavity. The cooling time is crucial; it depends on factors such as the thickness of the plastic part and the type of plastic. Thicker parts require longer cooling times. For a small, thin - walled plastic cup, the cooling time might be only a few seconds, while a thick - walled automotive component could take several minutes to cool properly.

- Ejection: After the plastic has cooled and solidified sufficiently, the mold opens. The moving mold plate moves away from the fixed mold plate. Then, the ejection system is activated. The ejector pins push the now - solid plastic part out of the mold cavity. The part can then be collected, either by hand or by an automated robotic arm, and moved to the next stage of production, such as quality inspection or post - processing.

Manufacturing Innovations

Advanced Materials in Use

In the realm of 2 - plate injection moulding, the choice of materials has a profound impact on the final product's quality and performance. High - performance engineering plastics are becoming increasingly popular. For example, polyetheretherketone (PEEK) is a remarkable high - performance engineering plastic. It has a melting point as high as 343°C, which allows products made from it to withstand extreme temperature conditions. In the aerospace industry, PEEK is used to manufacture components such as aircraft interior parts, where it offers excellent heat resistance, chemical stability, and mechanical strength. This ensures that the parts can maintain their integrity even in harsh environments, contributing to the overall safety and reliability of the aircraft.

Another category is new composite materials. Continuous fiber - reinforced thermoplastic composites, like those developed by some leading companies, have gained significant traction. These composites combine the advantages of continuous fibers (such as carbon fiber or glass fiber) and thermoplastic resins. They offer a high strength - to - weight ratio, which is crucial in applications where weight reduction is a priority, such as in the automotive industry. For instance, in the production of car body panels, these composite materials can reduce the vehicle's weight, thereby improving fuel efficiency. At the same time, they maintain high levels of impact resistance, ensuring the safety of the vehicle occupants. According to research, vehicles using such lightweight composite materials can achieve a fuel efficiency improvement of up to 10 - 15% compared to those made entirely of traditional materials.

Precision Manufacturing Technologies

Precision is the key to high - quality two - plate injection moulding, and it is achieved through advanced manufacturing technologies. High - speed milling is one such technology that has revolutionized the mould - making process. With high - speed milling, the cutting speed can be several times higher than that of conventional milling. This not only significantly improves the processing efficiency but also enhances the surface finish of the mould. For example, in the production of complex - shaped moulds for high - end consumer electronics, high - speed milling can achieve a surface roughness of less than 0.1μm, which is crucial for ensuring the smoothness and aesthetics of the final plastic products.

Electrical discharge machining (EDM) is another important precision manufacturing technology. It works on the principle of using electrical discharges to erode the material from the workpiece. EDM is especially useful when dealing with hard and brittle materials or when creating intricate shapes in the mould. In the production of injection moulds with very fine details, such as those for producing micro - sized plastic components used in medical devices, EDM can accurately create features with tolerances as small as ±0.001 mm. This level of precision ensures that the final plastic parts meet the strict quality requirements of the medical industry, where even the slightest deviation can have significant consequences.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of innovative design manufacturing in 2 - plate injection moulding. Customization lies at the heart of our services. We recognize that each client has unique requirements, whether it's in terms of product shape, functionality, or material selection. For example, when a client in the medical device industry approached us, they needed a highly precise plastic component with complex internal structures. Through in - depth communication and advanced design software, we were able to create a customized two - plate injection moulding solution that met their strict quality and design standards.

Moreover, we heavily invest in technology research and development. By keeping up with the latest trends in materials and manufacturing technologies, we can offer our clients the most advanced solutions. Our R & D team constantly explores new materials and refines manufacturing processes. This enables us to provide high - quality products with shorter lead times, helping our clients gain a competitive edge in the market. We believe that continuous innovation and customization are the keys to success in the field of 2 - plate injection moulding, and we are committed to delivering value - added services to every client.

FAQ about 2 Plate Injection Moulding

What are the main advantages of 2 plate injection moulding over other moulding methods?

Two - plate injection moulding offers several key advantages. Firstly, it has a simpler structure compared to methods like three - plate injection moulding. With only two main plates (the fixed and moving plates), the mould design and manufacturing are less complex, leading to lower initial tooling costs. For example, the absence of an additional middle plate in a two - plate mould reduces the number of components to be machined and assembled.

Secondly, in terms of production efficiency, two - plate injection moulding generally has a shorter cycle time. Since there are fewer components to move during the opening and closing of the mould, the process can be faster. This results in higher production volumes in a given time period.

Finally, two - plate injection moulding is often more cost - effective for large - scale production runs. The lower tooling cost and higher production efficiency contribute to reducing the overall cost per unit of the final product.

How to deal with the problem of warping in 2 plate injection moulding products?

There are several effective ways to address warping issues. One approach is to adjust the process parameters. For instance, increasing the melt temperature can reduce the viscosity of the molten plastic, allowing it to flow more easily into the mould cavity and reducing internal stresses that cause warping. Additionally, optimizing the cooling time and rate is crucial. Ensuring uniform cooling across the product can prevent uneven shrinkage, which is a major cause of warping. This can be achieved by improving the design of the cooling channels in the mould.

Another method is to optimize the product structure design. Using ribs or adding thickness in critical areas can enhance the product's structural integrity and reduce the likelihood of warping. For example, adding ribs to a flat plastic panel can increase its stiffness and prevent it from bending or warping during the cooling process.

Can complex - shaped products be produced by 2 plate injection moulding?

Complex - shaped products can be produced by 2 - plate injection moulding, but it comes with certain considerations. While the basic two - plate mould structure is relatively straightforward, producing complex - shaped products may require additional design features. For example, the use of side - action mechanisms, such as slides or lifters, can be incorporated into the mould to create undercuts or other complex features. These mechanisms allow the mould to form intricate shapes while still being able to eject the finished product.

However, there are limitations. If the product has extremely complex internal structures or multiple deep undercuts in different directions, it may pose challenges for a two - plate mould. In such cases, additional manufacturing steps or more complex mould designs might be necessary. But with proper design and engineering, many complex - shaped products can be successfully produced using 2 - plate injection moulding, as long as the mould is designed to accommodate the specific shape requirements.