Introduction

In recent years, 3D printing has emerged from the shadows of technological novelty to become a cornerstone in various industries. But what exactly is 3D printing? At its core, 3D printing, also known as additive manufacturing, is the process of creating three - dimensional objects from a digital file. Instead of subtracting material like traditional manufacturing methods such as milling or carving, 3D printing builds objects layer by layer, adding material precisely where it's needed.

The manufacturing landscape has long been plagued by issues like high production costs, especially for small - batch runs, long lead times, and limitations in design complexity. This is where innovative 3D printing solutions step in. They have the potential to revolutionize the way we produce goods, from simple prototypes to complex end - use parts. By leveraging advanced materials, improved printing techniques, and intelligent software, these solutions can offer unprecedented levels of customization, cost - effectiveness, and speed.

In the following sections, we will delve into the various aspects of innovative 3D printing solutions, exploring how they work, the materials used, their applications across different industries, and the advantages they bring over traditional manufacturing methods.

The Basics of 3D Printing

How 3D Printing Works

At its most fundamental level, 3D printing is all about turning digital blueprints into tangible, three - dimensional objects. The process begins with a 3D model, which can be created using computer - aided design (CAD) software, 3D scanners, or even by modifying pre - existing digital models. This digital model serves as the instruction manual for the 3D printer.

Once the 3D model is ready, it goes through a process called slicing. Specialized software divides the 3D model into hundreds or even thousands of extremely thin horizontal layers. Each layer represents a cross - section of the final object. The thickness of these layers can vary, but it is typically in the range of 0.1 to 0.3 millimeters for consumer - grade printers, and even thinner (down to 0.025 mm or less) for high - end industrial printers.

After slicing, the printer gets to work. It reads the sliced data and starts depositing materials layer by layer, following the precise patterns defined in the digital model. For example, in a fused deposition modeling (FDM) printer, which is one of the most common types of 3D printers, a spool of thermoplastic filament is melted and extruded through a heated nozzle. The nozzle moves precisely according to the layer data, depositing the molten plastic in the right place. As the plastic cools, it solidifies, bonding to the layer below it. This process continues until all the layers are printed, and the final 3D object is formed.

As shown in the table above, innovative 3D printing solutions clearly have the upper hand in multiple aspects compared to traditional methods. They offer a wider range of materials, faster production speeds, and higher precision, making them more suitable for a variety of industries and applications with diverse requirements.

Applications of Innovative 3D Printing Solutions

In Healthcare

In the healthcare industry, innovative 3D printing solutions have opened up a world of possibilities. One of the most significant applications is in the creation of custom - made prosthetics. For example, a patient with an amputated limb can now receive a prosthetic that is tailored to their exact body shape and movement patterns. A 3D scanner is first used to capture the precise geometry of the residual limb. Then, using specialized 3D modeling software, a design for the prosthetic is created. The 3D printer then manufactures the prosthetic, layer by layer, using materials such as high - strength polymers. This personalized approach not only improves the fit and comfort of the prosthetic but also enhances the patient's mobility and quality of life.

Another remarkable application is in the production of anatomical models. Surgeons can now use 3D printing to create highly detailed, life - sized models of organs, bones, and other anatomical structures. These models are invaluable for surgical planning. For instance, before performing a complex heart surgery, a surgeon can study a 3D - printed model of the patient's heart to better understand its unique anatomy, identify potential challenges, and plan the surgical procedure in advance. This can lead to shorter surgery times, reduced risks, and better patient outcomes. Some companies are even exploring the use of 3D printing to create living tissue and organ constructs, bringing us closer to the possibility of printing replacement organs for transplantation.

In Aerospace

The aerospace industry has been quick to embrace innovative 3D printing solutions due to the numerous advantages they offer. One of the key applications is in the manufacturing of complex and lightweight components. For example, engine parts such as turbine blades can be 3D - printed using high - temperature - resistant metal alloys. These 3D - printed blades can be designed with intricate internal cooling channels, which are extremely difficult to manufacture using traditional methods. By optimizing the internal structure, the blades can operate more efficiently, reducing fuel consumption and emissions.

Weight reduction is a crucial factor in aerospace, as every kilogram saved can lead to significant fuel savings over the lifespan of an aircraft. 3D - printed components can be designed with lattice structures that maintain strength while minimizing weight. A study by a leading aerospace manufacturer found that by using 3D - printed parts, they were able to reduce the weight of certain aircraft components by up to 40%. This not only improves fuel efficiency but also increases the aircraft's payload capacity and range. Additionally, 3D printing allows for the on - demand production of spare parts. Instead of maintaining large inventories of spare components, airlines can simply print the parts they need when required, reducing storage costs and improving maintenance efficiency.

In Automotive

In the automotive industry, 3D printing has become an essential tool for both prototyping and production. During the design phase, car manufacturers can use 3D printers to quickly create prototypes of new vehicle parts or even entire concept cars. This allows designers to test and refine their ideas much faster than with traditional prototyping methods. For example, a design team can print a prototype of a new car dashboard within a few days. They can then use this prototype to evaluate ergonomics, functionality, and aesthetics, making adjustments to the design as needed. This iterative process can significantly reduce the time it takes to bring a new product to market.

As for production, 3D printing is being used to manufacture custom - made parts for high - end and specialty vehicles. Some luxury car manufacturers are offering customers the option to customize certain interior components, such as door handles or center consoles, through 3D printing. This level of customization allows customers to create a unique driving experience. Moreover, 3D printing can be cost - effective for small - batch production runs. A small automotive parts company might use 3D printing to produce a limited number of specialized parts for a niche market. Since 3D printing doesn't require expensive tooling and setup like traditional manufacturing methods, the cost per unit for small - batch production can be significantly lower.

Yigu Technology's Perspective

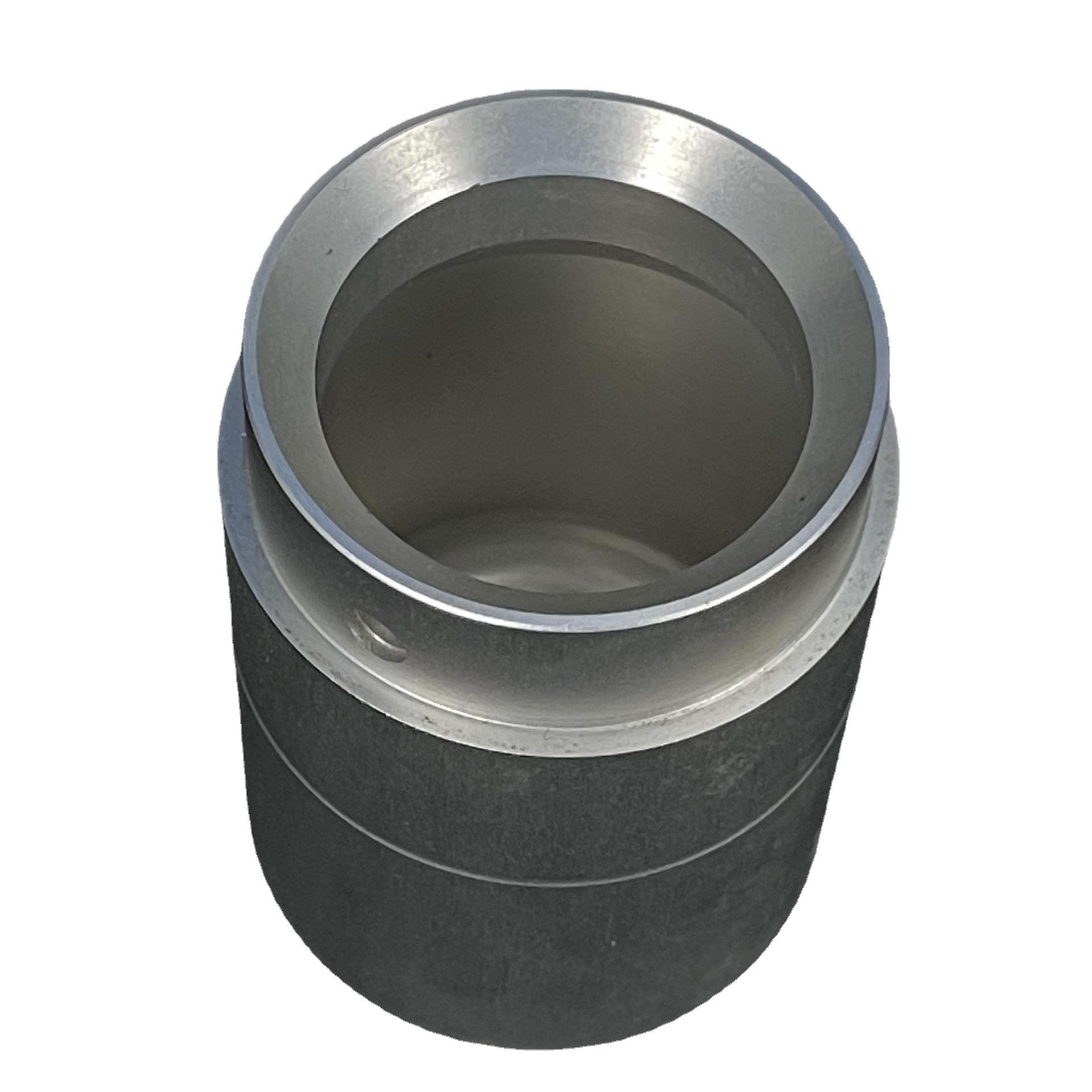

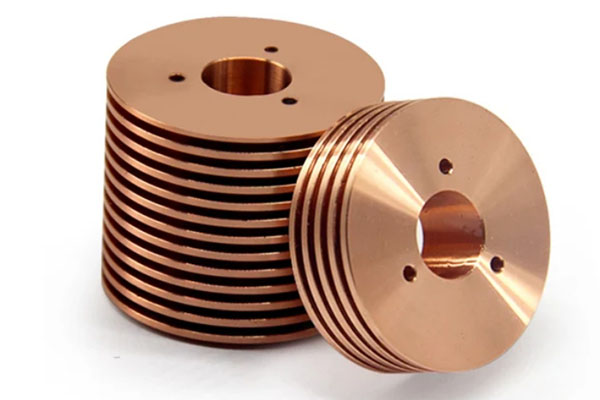

As a non - standard plastic metal products custom supplier, Yigu Technology has witnessed firsthand the positive impacts of innovative 3D printing solutions on custom product production.

First and foremost, these solutions offer far more design possibilities. In traditional manufacturing, complex geometries often require expensive and time - consuming tooling. However, with 3D printing, designers can let their creativity run wild. For example, when creating custom - shaped plastic components, Yigu Technology can now design intricate internal structures or unique outer contours that were previously unfeasible. This not only meets the specific functional requirements of customers but also adds value to the products through unique designs.

Secondly, the production cycle is significantly shortened. In the past, for small - batch production of non - standard metal parts, the process from design to prototype often took weeks due to the need for mold making and multiple processing steps. Now, with innovative 3D printing solutions, Yigu Technology can produce high - quality prototypes within a few days. This rapid turnaround allows for faster product development and quicker response to market demands, giving our customers a competitive edge.

In conclusion, innovative 3D printing solutions have become an indispensable part of Yigu Technology's production process, enabling us to provide better - quality custom products more efficiently.