Mastering Machining Aluminum: A Complete Guide to Techniques and Best Practices

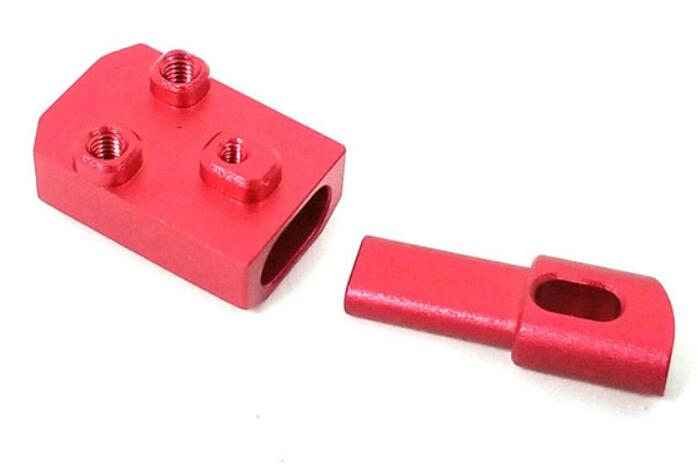

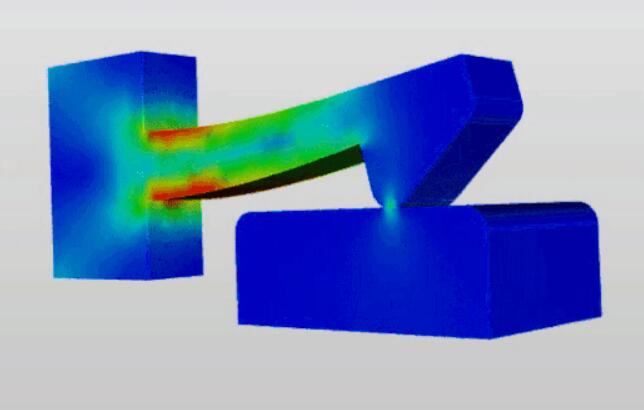

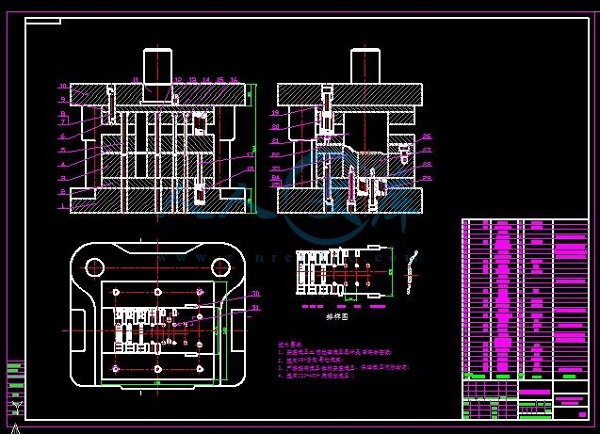

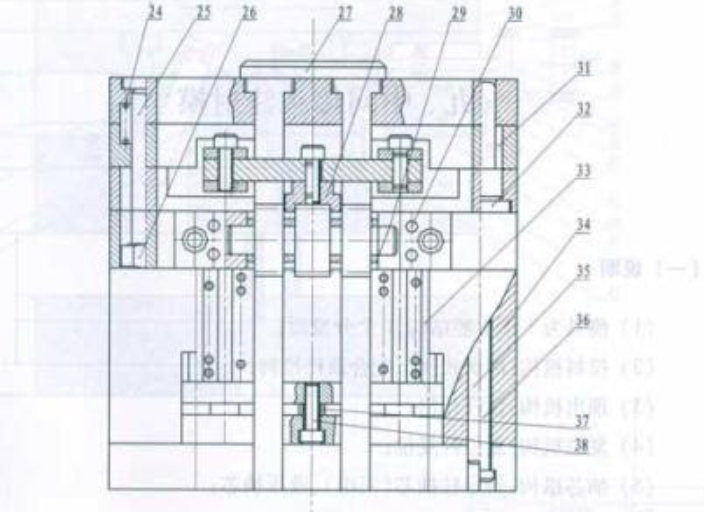

Aluminum machining is a cornerstone of modern manufacturing, prized for its versatility, strength-to-weight ratio, and excellent machinability. However, achieving optimal results—from high-speed production to flawless surface finishes—requires a deep understanding of the material's unique characteristics and the right application of tools and techniques. This comprehensive guide delves into the core principles and advanced strategies for […]