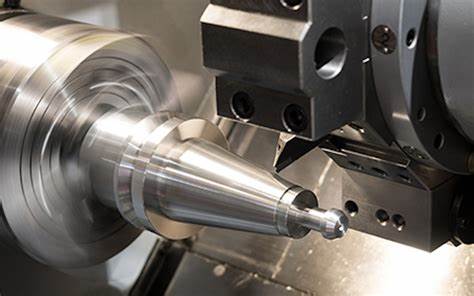

What Are the Critical Factors for Sourcing High-Quality CNC Machined Components?

The sourcing of high-quality CNC machined components is a strategic engineering decision that balances material properties, manufacturing capabilities, precision requirements, and total cost of ownership to achieve reliable performance in the final assembly. In today's precision-driven manufacturing landscape, CNC machined components are the fundamental building blocks of everything from medical devices to aerospace systems. However, […]