Injection Production Process: A Comprehensive Guide

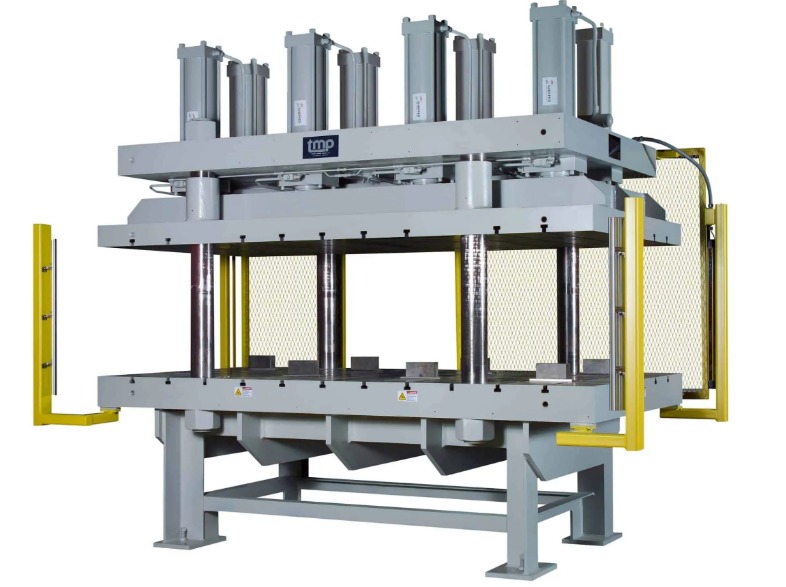

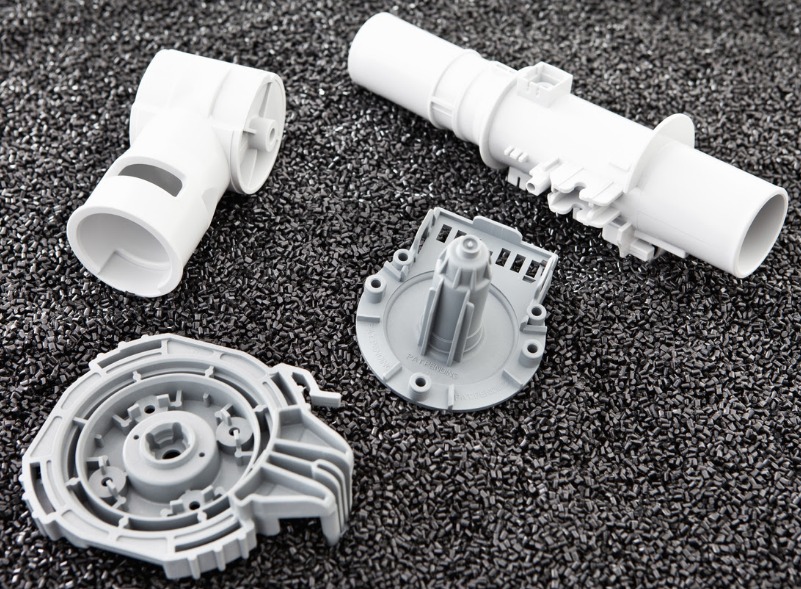

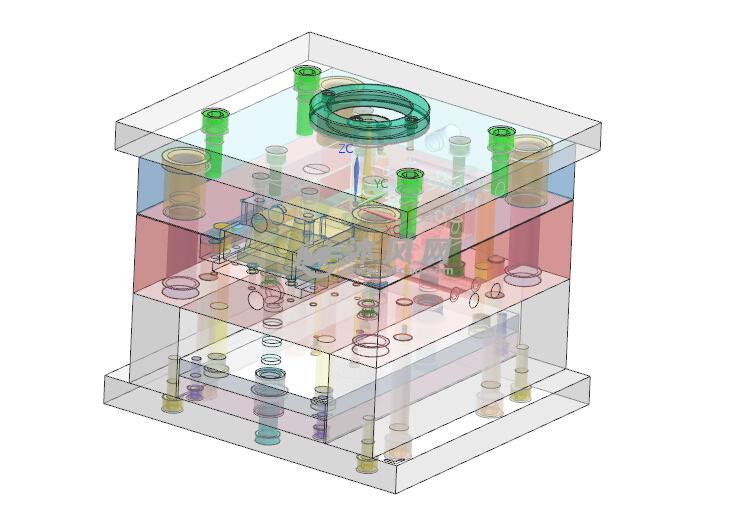

Introduction What is Injection Production Process The injection production process is a widely used manufacturing method in the plastics industry. It involves injecting molten material, typically plastic, into a mold cavity under high pressure. This process allows for the creation of complex and precise plastic parts with high production efficiency. Here's a step - by […]