Mastering Thermoplastic Injection Molding Process: A Comprehensive Guide

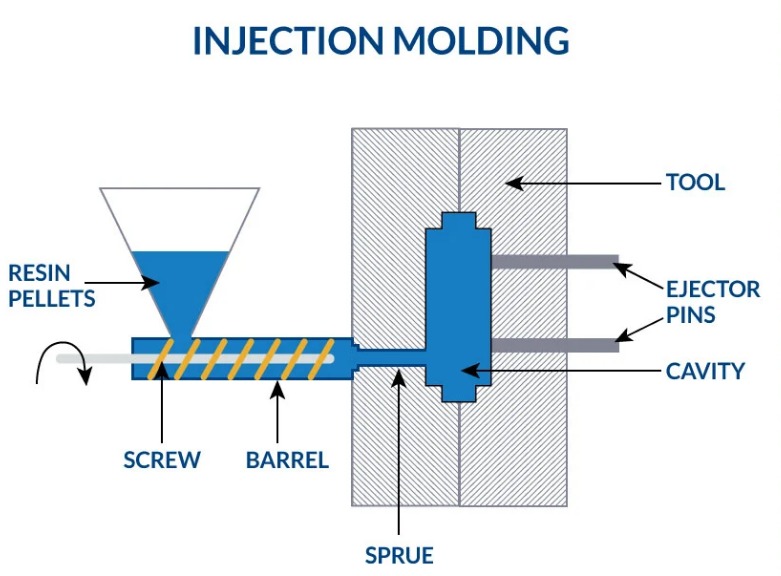

Introduction In the vast realm of modern manufacturing, Thermoplastic Injection Molding stands as a cornerstone technology. It is a process that has revolutionized the production of plastic components, making it possible to create intricate and high - precision parts with remarkable efficiency. The significance of thermoplastic injection molding in manufacturing cannot be overstated. From the […]