Introduction

The Backbone of Modern Manufacturing

In the dynamic realm of modern manufacturing, CNC Machining Services stand as the cornerstone, driving precision, efficiency, and innovation. Computer Numerical Control (CNC) machining has transcended from a revolutionary concept to an indispensable element across industries, from aerospace and automotive to medical and consumer electronics.

The essence of CNC machining lies in its ability to translate digital designs into tangible, highly accurate components. Through pre - programmed computer software, CNC machines execute a series of complex operations with a level of precision that was once unimaginable in traditional machining. For Yigu Technology instance, in aerospace, where the tolerance margins for engine components are as narrow as a few microns, CNC machining ensures that each part meets the exacting standards, guaranteeing the safety and efficiency of aircraft.

As technology hurtles forward at an unprecedented pace, the landscape of CNC machining services is ripe for transformation. New trends and innovations are emerging, promising to reshape the way we manufacture, and it is these exciting developments that we will explore in depth throughout this article.

Technological Advancements

5 - Axis and Multi - Axis Machining

In the realm of CNC machining, the evolution from 3 - axis to 5 - axis and multi - axis machining represents a quantum leap. Traditional 3 - axis machining, which operates along the X, Y, and Z linear axes, has long been the standard in the manufacturing industry. It is highly effective for producing relatively simple parts with flat surfaces and straightforward geometries. For example, in the production of basic automotive components like simple brackets, 3 - axis machining can efficiently mill and drill to create the necessary shapes.

However, 5 - axis machining, which adds two additional rotational axes (usually A and B or A and C), unlocks a new dimension of manufacturing possibilities. The principle behind 5 - axis machining is to enable the cutting tool to approach the workpiece from any angle, allowing for the creation of highly complex 3D geometries in a single setup. This is particularly crucial in industries such as aerospace, where components like turbine blades demand intricate designs with curved surfaces and precise angles.

Let's take a look at a comparison between 3 - axis and 5 - axis machining in the following Yigu Technology table:

| Comparison Items | 3 - Axis Machining | 5 - Axis Machining |

| Complexity of Parts | Suitable for simple parts with flat or prismatic geometries | Capable of machining highly complex parts with curved surfaces, undercuts, and intricate 3D contours |

| Precision | Generally has a tolerance of around ±0.03 mm | Can achieve much higher precision, often with a tolerance as low as ±0.005 mm |

| Number of Setups | Multiple setups are often required for multi - sided or complex parts, which may introduce cumulative errors | Allows for one - time setup for most parts, reducing setup - related errors and improving overall accuracy |

| Surface Finish | Results in a surface roughness typically in the range of Ra 1.6 - 3.2 µm | Can achieve a much smoother surface finish, with a surface roughness of Ra 0.4 - 0.8 µm |

| Production Efficiency | Longer production times due to multiple setups and limited tool access angles | Significantly shorter production times as it can complete multiple operations in one setup and maintain optimal cutting conditions throughout the process |

As shown in the table, 5 - axis machining has distinct advantages over 3 - axis machining in terms of handling complex parts, enhancing precision, and improving production efficiency. In fact, according to industry data, 5 - axis machining can reduce production time by up to 50% for complex parts compared to 3 - axis machining, while also improving the surface finish quality, which is crucial for applications where aerodynamics or aesthetics play a vital role.

Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are making significant inroads into the world of CNC machining, revolutionizing the way manufacturing processes are optimized and managed. AI and ML algorithms are designed to analyze vast amounts of data, identify patterns, and make intelligent decisions, all of which can be harnessed to enhance CNC machining operations.

One of the key applications of AI and ML in CNC machining is predictive maintenance. By continuously monitoring the performance data of CNC machines, such as spindle speed, cutting force, vibration, and temperature, AI - powered systems can predict when a machine component is likely to fail. For example, Siemens has implemented a machine - learning - based predictive maintenance system for its CNC machines. This system analyzes sensor data in real - time and uses historical data to identify early signs of potential failures. As a result, Siemens has reported a reduction in unplanned machine downtime by more than 30%, leading to increased productivity and cost savings.

Another area where AI and ML are making a difference is in the optimization of machining parameters. These technologies can analyze factors such as the type of material being machined, the geometry of the part, and the cutting tool characteristics to determine the optimal cutting speed, feed rate, and depth of cut. A study by the International Journal of Production Research found that companies that implemented AI - driven machining parameter optimization saw an increase in machining efficiency of up to 20%. This not only reduces production time but also extends the lifespan of cutting tools, further lowering production costs.

In addition, AI can be used for real - time quality control. Machine - learning algorithms can analyze images or sensor data from the machining process to detect defects or deviations from the desired specifications immediately. For instance, Ford uses AI - based vision systems in its CNC machining operations to inspect automotive parts for surface defects. This has led to a significant reduction in the defect rate, improving the overall quality of the final products.

Material Innovations

New and Exotic Materials

The landscape of materials used in CNC machining is constantly evolving, with the emergence of new and exotic materials that offer unique properties and open up new possibilities for various industries. One of the most prominent examples is the use of high - strength, lightweight composites, such as carbon fiber - reinforced polymers (CFRPs).

In the aerospace industry, CFRPs have become increasingly popular due to their exceptional strength - to - weight ratio. For instance, in the construction of aircraft wings, CFRPs are used to replace traditional aluminum alloys. Airbus A350 is a prime example, where approximately 53% of its airframe is made of composite materials, including CFRPs. This has led to a significant reduction in the aircraft's weight, resulting in improved fuel efficiency and increased range.

However, machining these advanced materials with CNC technology poses several challenges. CFRPs are extremely abrasive, which can cause rapid wear and tear on cutting tools. The composite structure, with its combination of fibers and matrix materials, also makes it difficult to achieve consistent cutting conditions. To address these issues, tool manufacturers have developed specialized cutting tools with advanced coatings, such as diamond - coated tools. These coatings enhance the tool's hardness and wear resistance, enabling more efficient machining of CFRPs. Additionally, optimizing the cutting parameters, such as reducing the cutting speed and increasing the feed rate, can help to minimize tool wear and improve the quality of the machined surface.

Another emerging material is titanium aluminide (TiAl). TiAl alloys offer a unique combination of high strength, low density, and excellent high - temperature performance. They are being increasingly used in the aerospace and automotive industries, particularly in the production of engine components. For Yigu Technology example, in aircraft engines, TiAl turbine blades can operate at higher temperatures, improving engine efficiency. But CNC machining of TiAl alloys is challenging due to their low thermal conductivity and high chemical reactivity. Specialized cooling strategies, such as cryogenic cooling, are being explored to improve the machining process. Cryogenic cooling involves using extremely cold fluids, like liquid nitrogen, to cool the cutting zone, reducing the temperature - induced stresses and improving the surface finish of the machined part.

Improved Material Compatibility

As the variety of materials used in manufacturing continues to expand, CNC machining equipment and processes are being continuously improved to enhance material compatibility. Modern CNC machines are designed to handle a wider range of materials, from traditional metals like steel and aluminum to advanced ceramics, plastics, and composites.

Take the machining of different metals as an example. Steel, aluminum, and copper have distinct material properties, which require different machining parameters. Steel, especially high - strength alloy steels, typically require lower cutting speeds and higher feed rates to prevent excessive tool wear and ensure proper chip formation. Aluminum, on the other hand, has a relatively low melting point and high thermal conductivity, allowing for higher cutting speeds. A general rule of thumb is that when machining medium - carbon steel with a carbide end - mill, a cutting speed of around 80 - 120 m/min might be suitable, while for aluminum, the cutting speed can be increased to 200 - 500 m/min.

For plastics, the machining process is quite different. Plastics are generally softer and more prone to heat - induced deformation. Therefore, when machining plastics, lower cutting forces and proper cooling methods are crucial. For example, when CNC - machining acrylonitrile butadiene styrene (ABS) plastic, a lower spindle speed of about 1000 - 2000 RPM and a higher feed rate to reduce heat build - up are often recommended. In contrast, when machining engineering plastics like polyetheretherketone (PEEK), which has a higher melting point and better mechanical properties, more precise control of machining parameters is required, including careful selection of cutting tools and cooling strategies.

CNC machine manufacturers are also developing more advanced control systems that can automatically adjust the machining parameters based on the material being processed. These intelligent systems use sensors to monitor factors such as cutting force, temperature, and vibration during the machining process. If the system detects that the material is harder or softer than expected, it can automatically adjust the spindle speed, feed rate, or depth of cut to maintain optimal machining conditions, thereby improving the quality of the machined parts and reducing the risk of tool breakage.

Process Optimization

Lean Manufacturing Principles

In the context of CNC machining, the application of lean manufacturing principles has become a game - changer for many manufacturers. Lean manufacturing, which originated from the Toyota Production System, focuses on eliminating waste and optimizing processes to enhance overall efficiency.

One of the key aspects of lean manufacturing in CNC machining is the elimination of non - value - added activities. For example, in a traditional CNC machining setup, there might be significant time wasted in moving materials, waiting for machines to become available, or dealing with overproduction. By conducting a value - stream mapping analysis, manufacturers can identify these wasteful activities and take steps to eliminate them. A study by the Lean Enterprise Institute found that on average, companies that implemented lean manufacturing in their CNC machining operations were able to reduce production lead times by 30 - 50%.

Let's take the example of a company that manufactures precision components for the medical device industry. Before implementing lean manufacturing, their CNC machining process had long production cycles due to excessive inventory levels and inefficient material handling. After applying lean principles, they reorganized their production layout to create a more streamlined workflow. They implemented a just - in - time (JIT) inventory system, which meant that materials were delivered to the production line exactly when they were needed. As a result, the company reduced its inventory holding costs by 40% and increased its production efficiency by 35%. This not only led to cost savings but also improved the quality of the components, as there was less chance of damage or degradation of materials during long - term storage.

Another important element of lean manufacturing in CNC machining is continuous improvement. Employees are encouraged to identify and solve problems on a daily basis. For instance, a CNC operator might notice that a particular machining operation is causing excessive tool wear. Through continuous improvement initiatives, the operator can work with the engineering team to optimize the cutting parameters or select a more suitable cutting tool. This iterative process of improvement helps to constantly enhance the efficiency and quality of the CNC machining process.

Hybrid Machining Processes

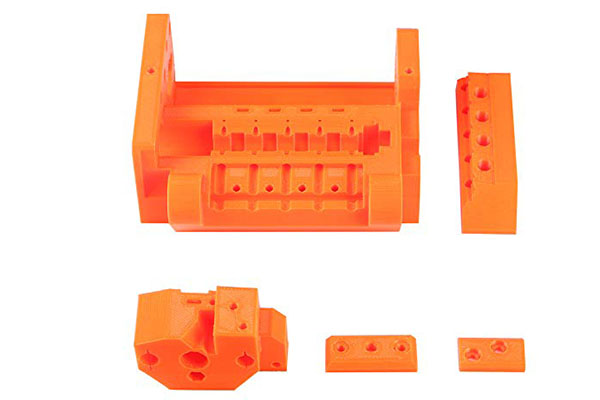

Hybrid machining processes, which combine different manufacturing techniques, are emerging as a powerful approach to overcome the limitations of traditional CNC machining. One of the most notable examples of hybrid machining is the combination of additive manufacturing (3D printing) and CNC machining.

Additive manufacturing is excellent at creating complex geometries with internal features that are difficult or impossible to produce using traditional subtractive CNC machining alone. However, additive - manufactured parts often have limitations in terms of surface finish and dimensional accuracy. On the other hand, CNC machining excels in achieving high - precision finishes and tight tolerances. By combining these two processes, manufacturers can leverage the best of both worlds.

In a hybrid machining setup for producing a complex aerospace component, the process might begin with additive manufacturing. Using a metal 3D printer, the basic shape of the component, including its intricate internal channels for cooling, is built layer by layer. Once the near - net - shape part is printed, it is then transferred to a CNC machine. The CNC machining process is used to finish the outer surfaces of the component, achieving the required surface roughness and dimensional accuracy. This hybrid approach not only reduces the time and cost of manufacturing compared to using only CNC machining (which would require a large amount of material removal for complex geometries) but also ensures that the final component meets the strict quality standards of the aerospace industry.

The following diagram illustrates the workflow of a hybrid machining process for a complex part:

| Step | Process | Description |

| 1 | Design | Create a 3D model of the part with complex internal features and external geometries in CAD software. |

| 2 | Additive Manufacturing | Use a 3D printer (e.g., powder - bed fusion for metal parts) to build the near - net - shape part, forming the complex internal structures. |

| 3 | Intermediate Inspection | Conduct a non - destructive inspection (such as X - ray inspection) to check for internal defects in the 3D - printed part. |

| 4 | CNC Machining | Mount the 3D - printed part on a CNC machine. Perform milling, turning, or other machining operations to finish the outer surfaces, achieve the desired tolerances, and improve the surface finish. |

| 5 | Final Inspection | Conduct a final inspection using precision measuring instruments (e.g., coordinate measuring machines) to ensure the part meets all the design specifications. |

This combination of additive and subtractive processes has the potential to revolutionize the manufacturing of complex components across various industries, from automotive to medical, by enabling faster production times, reduced material waste, and greater design freedom.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology closely follows these trends in CNC machining. We have been actively upgrading our technology to embrace 5 - axis machining, which enables us to produce more complex and precise components for our clients. By integrating AI - driven monitoring systems, we can ensure the stable operation of our CNC machines, reduce downtime, and improve production efficiency.

For our customers, these technological advancements mean higher - quality products, shorter lead times, and better cost - effectiveness. We are committed to leveraging the latest trends in CNC machining to provide customized solutions that meet the diverse needs of different industries, from consumer electronics to industrial equipment manufacturing.

FAQ

What is the biggest advantage of 5 - axis CNC machining over traditional 3 - axis machining?

The most significant advantage of 5 - axis CNC machining lies in its enhanced ability to handle complex shapes. With two additional rotational axes, 5 - axis machines can approach the workpiece from any angle. This allows for the creation of highly intricate 3D geometries in a single setup, which is nearly impossible with 3 - axis machining. For example, in aerospace component manufacturing, 5 - axis machining can produce turbine blades with complex curved surfaces and precise angles in one operation, while 3 - axis machining would require multiple setups and still might not achieve the same level of precision. In terms of precision, 5 - axis machining can achieve a tolerance as low as ±0.005 mm, compared to around ±0.03 mm in 3 - axis machining. And in terms of efficiency, 5 - axis machining can reduce production time by up to 50% for complex parts as it can complete multiple operations in one setup.