In the field of machining, material selection directly determines product performance, processing efficiency and cost control, while plastic for machiningand metal materials are the two most commonly used categories. The two are significantly different in terms of characteristics, processing technology, application scenarios, etc., and are suitable for different processing needs. This article will systematically compare the advantages and disadvantages of plastics and metals in machining from the three core dimensions of material characteristics, processing technology, and application fields, combined with real cases and data support, to provide reference for you to accurately select processing materials, and finally supplement professional views and FAQs to comprehensively answer your core questions about the comparison between the two.

1. Introduction

With the diversified development of the manufacturing industry, the proportion of plastic for machining applications continues to increase, but metal materials still dominate high-strength and high-precision scenarios. According to industry statistics, in 2024, metal materials will account for 65% of the global machining materials market, and plastic materials will account for 35%, of which the growth rate of engineering plastics will reach 8.5%, which is significantly higher than the 2.3% of metal materials. The choice between plastic and metal needs to be comprehensively judged based on various factors such as processing needs, product performance requirements, and cost budget. The following will be a detailed comparison from the core dimensions to help you clearly understand the differences and adaptation scenarios between the two.

2. Material characteristics

2.1 Physical and chemical properties of plastics

The core physical characteristics of plastics are low density, and the density of common plastics for machining (such as PP, POM, PC) is between 0.9-1.5g/cm³, which is only 1/5-1/8 of steel and 1/3-1/2 of aluminum, with significant lightweight advantages. The toughness is good, and most plastics have a certain impact resistance, of which the impact strength of PC is 250 times that of ordinary glass; It has excellent electrical insulation, and the breakdown voltage is generally above 10kV/mm, which can effectively block current conduction. In terms of chemical properties, most plastics have good corrosion resistance, such as PP can withstand most strong acids and alkalis, PTFE can resist strong corrosive substances such as aqua regia, and is not easy to oxidize and rust, and does not require additional anti-corrosion treatment. However, plastics also have shortcomings, such as poor high temperature stability, and the thermal deformation temperature of most engineering plastics is between 100-150°C, which is much lower than that of metals; The mechanical strength is generally low, and the tensile strength is mostly between 40-80MPa, which is lower than that of steel (more than 400MPa).

2.2 Physical and chemical properties of metals

The core physical properties of metals are high mechanical strength, and the tensile strength of commonly processed metals such as steel and aluminum can reach 400-1000MPa, which can withstand large loads. The melting point of steel is generally above 1500°C, which can maintain stable performance in high temperature environments. It has good thermal and electrical conductivity, making it suitable for processing scenarios that require heat transfer or electrical conductivity. In terms of chemical properties, the chemical activity of metals varies greatly, and most metals (such as steel and iron) are prone to oxidation and rust in humid and acid-alkali environments, and need to be extended by electroplating, spraying and other anti-corrosion treatments. A few precious metals (such as stainless steel and titanium alloys) have good corrosion resistance but are more costly. In addition, the metal is dense and heavy, and the transportation and operation costs of the processed parts are relatively high.

2.3 The performance of the two in the processing process

During processing, the performance of plastics and metals is significantly different, as follows:

| Contrast dimensions | Plastic for machining | Metal material |

| Cutting difficulty | low, small cutting resistance, not easy to produce burrs | High, high cutting resistance, easy to produce burrs, and need additional polishing |

| Risk of thermal deformation | High, the processing temperature is too high and easy to soften and deform | Low, high temperature resistance, small thermal deformation during processing |

| Tool wear | Small, low requirements for tool hardness, and long tool service life | large, high requirements for tool hardness, and frequent tool replacement |

| Dimensional stability | Medium, some plastics (such as POM) have good stability, and hygroscopic plastics (such as PA) are easy to deform | high, small size deviation after processing, strong stability |

For example, a precision processing factory processes gears of the same specification, and when processing with POM (plastic), the cutting speed can reach 150m/min, and the tool service life can reach 5000 pieces; When machining with steel, the cutting speed can only reach 80m/min, the tool service life is only 2000 pieces, and additional polishing is required to remove burrs after processing.

3. Processing technology

3.1 Processing methods of plastics (such as CNC machining, injection molding, etc.)

Plastic for machining has a variety of processing methods to suit different production needs: CNC cutting is suitable for mass production of precision parts, which can ensure machining accuracy and control the dimensional deviation within ±0.01mm; Injection molding is suitable for large-scale production of parts with complex shapes, with high processing efficiency and low cost. Laser cutting is suitable for high-precision processing of thin plastic parts, with smooth and burr-free cutting surfaces; 3D printing is suitable for the processing of customized, low-volume parts, and can quickly realize the formation of complex structures. The core advantages of plastic processing are simple processes, low processing temperature and pressure requirements, and no need for complex pre-treatment processes, especially suitable for small and medium-sized enterprises.

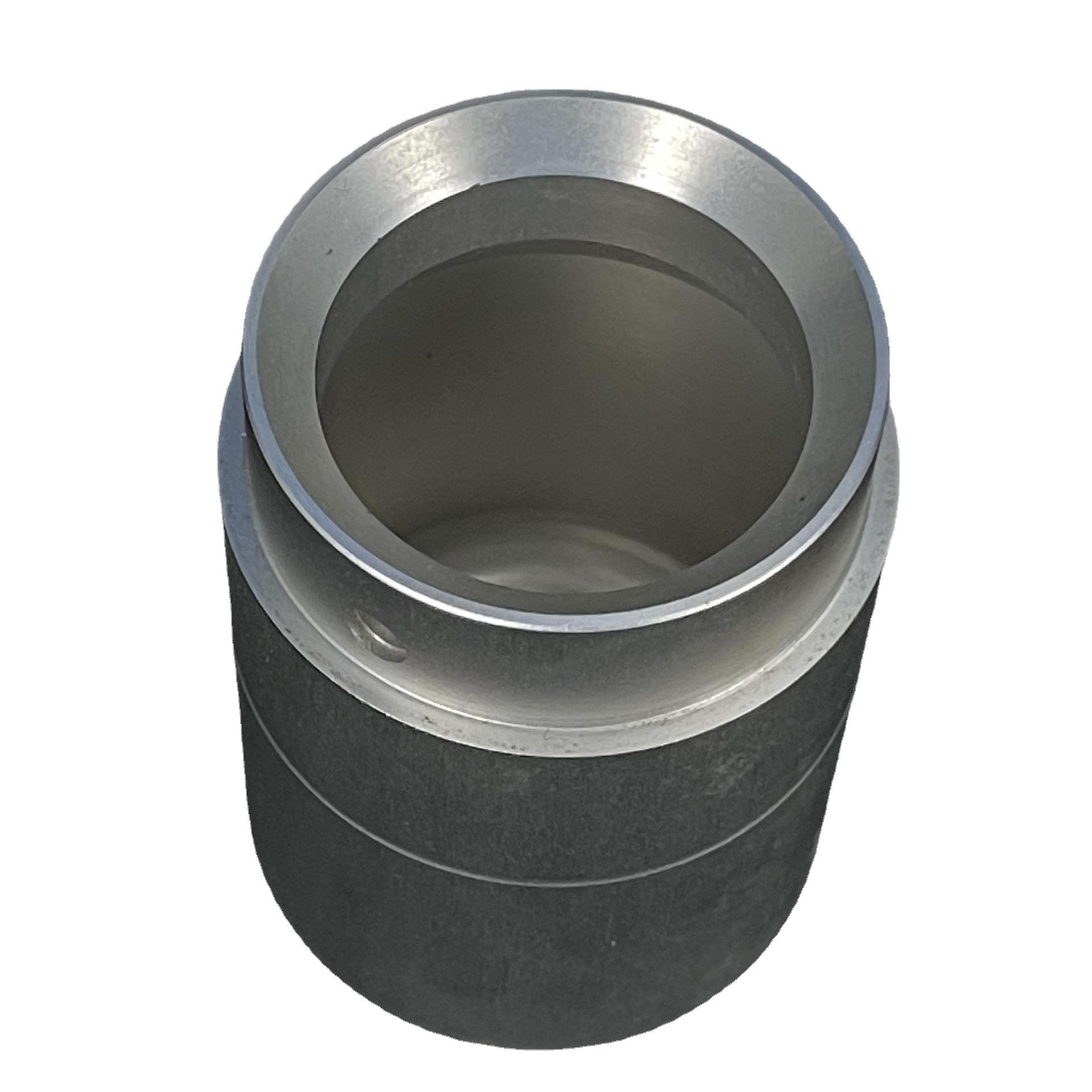

3.2 Metal processing methods (such as turning, milling, etc.)

The processing methods of metals are mainly traditional machining, including turning, milling, drilling, grinding, etc.: turning is suitable for processing round parts (such as shafts and sleeves); milling is suitable for processing complex contour parts such as planes and grooves; grinding is suitable for the finishing of high-precision parts, which can improve the surface roughness and dimensional accuracy of parts. In addition, metals can also be processed using forging, casting and other processes, but these processes are suitable for mass production, and subsequent machining needs to be optimized for accuracy. The process complexity of metal processing is high, and the requirements for equipment and technology are high, and some high-precision processing requires professional high-end equipment.

3.3 Comparison of processing efficiency and cost

In terms of processing efficiency, the overall efficiency of plastic processing is higher than that of metal: in mass production, the production efficiency of plastic parts in injection molding is 3-5 times that of metal turning processing; in precision machining, the cutting speed of CNC machined plastics is 1.5-2 times that of metal, and there is no need for additional polishing processes, further improving efficiency. In terms of cost, the comprehensive cost of plastic processing is lower, which is reflected in: raw material cost, the unit price of general plastics is only 1/3-1/2 of steel, the processing cost, the energy consumption of plastic processing is only 1/5-1/3 of metal, and the tool loss cost is only 1/4 of that of metal; According to data from a machinery factory, the comprehensive cost of PP plastic processing is 45% lower than that of steel pipes for processing the same number of chemical pipes.

4. Application fields

4.1 Examples of plastics in various industries

Plastic for machining is widely used in many industries due to its advantages of lightweight, corrosion resistance, and insulation: in the automotive industry, PP is used to process bumpers and interior panels, and PA is used to process engine transmission parts to achieve vehicle lightweight and improve fuel efficiency; In the electronics industry, PC is used to make mobile phones and computer shells, POM is used to process keyboard buttons, and PVC is used to make wire insulation to ensure insulation and accuracy; In the medical industry, PC is used to process surgical instrument shields, PTFE is used to make artificial blood vessels, and degradable PLA is used to process disposable medical consumables; In the chemical industry, PP and PTFE are used to process storage tanks and pipelines to resist corrosive environments. A new energy vehicle manufacturer used plastic to replace metal processing body parts, reducing the curb weight of the vehicle by 120kg and increasing the cruising range by 15%.

4.2 Examples of applications of metals in various industries

With the advantages of high strength and high stability, metal materials are indispensable in high-end manufacturing and heavy-duty scenarios: in the aerospace industry, titanium alloy and aluminum alloy are used to process aircraft fuselage structural parts and engine core components to ensure flight safety; In the machinery manufacturing industry, steel is used to process heavy-duty transmission components such as machine tool spindles and gearboxes to withstand large loads; In the construction industry, steel is used to process the load-bearing structure of bridges and factories to ensure structural stability; In the new energy industry, copper is used to process battery poles and cables, taking advantage of its excellent conductivity. An aerospace company uses titanium alloy to process aircraft engine blades, which can work stably in high temperature and high pressure environments, with a service life of 10,000 flight hours.

4.3 Advantages and disadvantages of different materials in specific applications

In specific application scenarios, the advantages and disadvantages of plastics and metals are complementary, as follows: in the application of lightweight automotive components, the advantages of plastics are light weight and low cost, and the disadvantages are insufficient strength; The advantage of metal is high strength, and the disadvantage is heavy weight and high cost. In the application of electronic equipment insulation components, the advantages of plastic are good insulation, flexible processing, and metal cannot be replaced; In the application of high-precision transmission components, the advantages of metal are strong dimensional stability and high strength, and plastic can only be replaced in low-load scenarios. In chemically corrosive environment applications, plastics have the advantages of good corrosion resistance, low maintenance costs, additional anti-corrosion treatment of metals, and short service life.

5. Conclusion

On the whole, plastic for machining and metal materials have their own advantages and disadvantages in machining: the core advantages of plastics are lightweight, good corrosion resistance, high processing efficiency, low cost, and excellent insulation, which are suitable for scenarios with low and medium loads, corrosion resistance, light weight, and high insulation requirements; The core advantages of metal are high mechanical strength, good high temperature stability, and high dimensional accuracy, which are suitable for heavy load, high temperature, high precision, high-end manufacturing and other scenarios. When choosing, it is necessary to make a comprehensive judgment based on the performance requirements, working environment, and cost budget of the product: if you pursue lightweight, low cost, and corrosion resistance, give preference to plastic; If high strength, high precision, and high temperature resistance are required, metal is preferred; In some scenarios, the composite structure of the two can be used to achieve complementary advantages. In the future, with the development of modified plastic technology, the application scenarios of plastics in machining will be further expanded, forming a more efficient and coordinated development pattern with metal materials.

Yigu Technology Perspective

Yigu Technology believes that plastic for machining and metal materials are not competitive substitutions, but synergistic and complementary relationships. Enterprises should abandon the single choice thinking of "non-plastic or gold" and accurately match materials according to specific processing needs. In the future, it is recommended to focus on the research and development and application of modified plastics, improve the strength and high temperature resistance of plastics through material modification, and expand their application in mid-to-high-end scenarios. At the same time, the composite structure of plastic and metal is reasonably designed, and under the premise of ensuring product performance, it realizes lightweight and cost optimization, and promotes the efficient and green development of the manufacturing industry.

FAQ

1. High-precision parts machining, choose plastic for machining or metal materials? If the accuracy is extremely high (within ±0.005mm) and bears the load, prefer metal materials (such as steel and aluminum alloys); If the accuracy requirements are medium (±0.01-±0.02mm) and do not need to bear large loads, high-precision plastics such as POM and PC can be chosen, which has higher processing efficiency and lower cost.

2. Can plastic replace metal in parts processing in high-temperature environments (such as above 150°C)? Ordinary plastics cannot be replaced, so you need to choose special high-temperature resistant plastics (such as PTFE, PEEK), which can reach a temperature of more than 200 °C and work stably in a high-temperature environment. If the temperature exceeds 260°C, metal materials (such as stainless steel, titanium alloy) should be selected.

3. Do plastic machined parts last less than metal? Not necessarily. In normal environments, metal parts have a longer service life; However, in corrosive environments, plastic parts (such as PP, PTFE) have a service life of 5-10 times longer than non-corrosive metals, and the maintenance cost is lower; By modifying the material, the service life of plastic parts can be further increased to close to the metal level.

4. Is it more cost-effective to choose plastic or metal for small batch customization? Give preference to plastic. For small-batch customized processing, plastics can be CNC machining or 3D printing, with short processing cycles (1-3 days) and low mold costs; Metalworking requires customized tools and tooling, long machining cycles (5-7 days), high costs, and metals are only considered when parts need to withstand large loads.