As a key link in product development and industrial manufacturing, machined prototypes(machined prototype) has always been the core bridge connecting the design concept and mass production. Whether it's high-precision components in aerospace or precision structures in medical devices, high-quality machined prototypes can help companies quickly verify designs, optimize processes, and reduce mass production risks. However, in the face of diverse process options, material properties and application scenarios, many engineers and R&D personnel will be confused: How to choose the right processing technology? What industries are different materials suitable for? What are the unique advantages of machined prototypes over methods such as 3D printing? This article will comprehensively dismantle the key knowledge points of machining prototypes for you from the four dimensions of core process, material application, advantage design, and full-process service, combined with real cases and practical data.

1. Core processes and technologies: "hard-core support" of machined prototypes

The precision and efficiency of machined prototypes are entirely dependent on the technical strength of the core processes and equipment. For R&D personnel, understanding the applicable scenarios of different machining technologies is the first step in ensuring that the prototype meets the design requirements.

1. Mainstream processing technology: full coverage from basic to high-precision

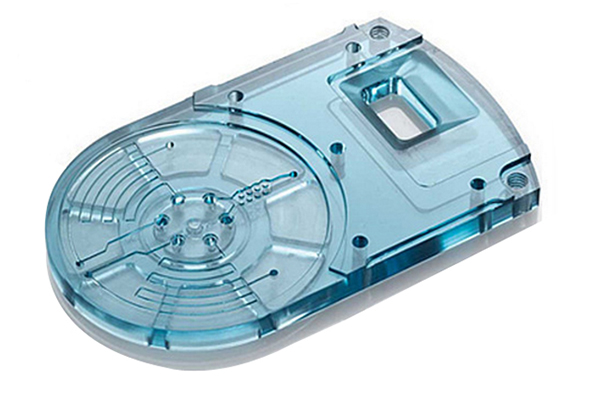

- CNC machining: As the core technology of machining prototypes, CNC machining controls machine tools through computer programs to complete cutting, drilling, and other operations, which has the advantages of high automation and stable precision. An auto parts company once used CNC machining to make a prototype of a gearbox, controlling the machining error within ±0.005mm, successfully shortening the R&D cycle by 30%.

- Milling and turning: Milling is mainly used for the machining of complex contours such as planes and grooves, while turning focuses on the rotational processing of shaft and disc parts, and the two are often used together. For example, in aerospace parts prototyping, milling is responsible for machining the blade contour and turning the shaft end structure to meet high precision requirements.

- 5-axis machining: For complex surface prototypes, five-axis machining can achieve multi-directional linkage cutting to avoid secondary clamping errors. The data shows that the prototype pass rate of 5-axis machining is 40% higher than that of traditional 3-axis machining, especially for precision-critical scenarios such as medical implants.

- Rapid prototyping machining: Combine CAD/CAM programming technology to quickly convert design drawings into physical prototypes. Modern programming software automatically optimizes cutting paths, increasing machining efficiency by more than 25% while reducing material waste.

2. Key Quality Indicators: Tolerance and Surface Finish

- Machining tolerances: The tolerance of ordinary machining prototypes can be controlled at ±0.01mm, and can reach ±0.001mm in high-precision scenarios, which is much higher than the conventional tolerance level of 3D printing. For example, in precision instrument gear prototypes, tight tolerance control ensures a 15% increase in transmission efficiency.

- Surface finish: Through post-processing such as grinding and polishing, the surface roughness of machined prototypes can be as low as Ra 0.8μm, which not only improves the appearance and texture, but also reduces friction losses. The prototype of a surgical instrument from a medical device company has been extended by 2 times after high-precision surface treatment.

2. Material selection and multiple applications: adapt to the needs of different industries

The material selection of machined prototypes directly affects their performance test results and application scenarios, and needs to be comprehensively considered in combination with material characteristics and industry requirements.

1. Commonly used prototype materials and characteristics

| Material type | Representative materials | Core features | Applicable scenarios |

| Metal material | Aluminum prototypes | Lightweight, easy to process, and low cost | Auto parts, electronic housings |

| Stainless steel machining | High strength and corrosion resistance | Medical equipment, industrial valves | |

| Plastic material | POM, nylon (plastic machining) | Wear resistance, good toughness, and dimensional stability | Gears, buckles and other structural parts |

| Composite materials | Carbon fiber reinforced plastic | High strength and light weight | Aerospace components |

2. Key industry application cases

- Aerospace prototypes: mostly use high-strength materials such as titanium alloy and stainless steel to make complex structural parts through five-axis machining. The engine blade prototype of an aviation company, made of titanium alloy machined, can withstand a high temperature of 1200°C after strength testing, meeting the requirements of high-altitude flight.

- Automotive prototypes: Aluminum prototypes are widely used in body structures due to their lightweight advantages, while engine block prototypes are made of cast iron to ensure wear resistance. A car company has machined a prototype of a new energy vehicle battery tray, and after crash testing, the structural strength has been improved by 20% compared with the traditional design.

- Medical Device Prototypes: Stainless steel and titanium alloys are the mainstream choices that meet biocompatibility and corrosion resistance requirements. For example, artificial joint prototypes, which are precision machined to ensure a fit to the human bone structure, have been verified by clinical trials to have an implantation success rate of over 98%.

- Functional testing: Select materials according to testing needs, such as high-strength plastics for impact testing and high-temperature alloys for high-temperature testing. The connector prototype of an electronics company was finally selected as POM material through comparative testing of different materials, which solved the problem of insufficient mating life.

3. Core principles of material selection

- Match the performance parameters of the final mass-produced materials to ensure that the test results have reference value;

- Balance processing difficulty and cost, and give priority to materials that are easy to process and cost-effective;

- Considering the test environment, such as high temperature and corrosive environments, corresponding weather-resistant materials should be selected.

3. Unique advantages and design points: Why choose machined prototypes?

Compared with other prototyping methods such as 3D printing and prototyping, machined prototypes have irreplaceable advantages in specific scenarios and have clear requirements for the design phase.

1. Core advantages of machined prototypes

- High-strength prototypes: Good material density and mechanical properties close to mass-produced products, especially suitable for functional tests such as structural strength and wear resistance. Comparative data shows that the tensile strength of metal machined prototypes is 30%-50% higher than that of 3D printed prototypes.

- Tight tolerance prototypes: As mentioned earlier, machined prototypes have much more tolerance control than 3D printing, making them suitable for design verification of precision parts.

- machined prototypes vs 3D printing: 3D printing is suitable for rapid production of complex structures and low-volume prototypes, but it is limited in strength, precision, and material selection; machined prototypes are more suitable for scenarios that require functional testing and high precision requirements. For example, in automotive engine piston prototyping, machined metal prototypes can accurately simulate actual working conditions, while 3D printed plastic prototypes cannot withstand high-temperature and high-pressure tests.

- Low-volume production: The process of machining prototypes can be directly migrated to low-volume mass production without the need for additional equipment and processes, helping enterprises quickly respond to market demands.

2. Key considerations during the design phase

- Design for manufacturability (DFM): Machinability needs to be considered at the beginning of the design, such as avoiding overly complex internal structures and reserving reasonable machining allowances. An appliance company's enclosure prototype was optimized by DFM for a 50% increase in machining cycles due to the initial design that did not take into account the milling path.

- Rapid tooling: For prototypes that require repeated testing, simple tooling can be designed to improve machining efficiency and consistency. For example, in the prototyping of a mobile phone frame, the use of custom tooling can reduce the processing time of a single piece from 2 hours to 40 minutes.

- Design verification: Assemble and perform performance tests through machined prototypes to detect design defects in a timely manner. The joint prototype of a robot company was found to have unreasonable tolerance of bearing mounting holes after testing, and the major losses in the mass production stage were avoided by adjusting the design scheme.

4. Whole process analysis and service model: closed loop from design to finished product

Understanding the production process and service model of machined prototypes can help enterprises connect with suppliers more efficiently and shorten the R&D cycle.

1. Complete process of machined prototypes

- Requirements communication and design confirmation: clarify the size, material, accuracy requirements and testing use of the prototype, and review the processing feasibility of CAD drawings;

- CAD/CAM programming and process planning: write machining programs according to drawings, plan cutting paths, select tools and machining parameters;

- Raw material preparation and processing: purchase corresponding materials and complete prototype processing through CNC machining, milling, turning and other processes;

- Post-processing: including deburring, heat treatment, surface treatment (anodizing, painting, etc.) to improve prototype performance and appearance;

- Quality inspection: use coordinate measuring instruments, hardness testers and other equipment to detect dimensional tolerances, surface roughness and mechanical properties to ensure compliance with requirements;

- Delivery and feedback: Prototypes are delivered to customers, testing feedback is collected, and adjustments can be made to quickly start secondary processing.

2. Mainstream service model

- Rapid Prototyping Service: Focuses on short cycle delivery, typically 3-7 days to complete prototyping, suitable for urgent R&D projects. Before the new product launch of an electronics company, 30 sets of product shell prototypes were completed within 5 days through rapid prototyping services, ensuring the smooth progress of the launch meeting.

- On-demand machining: Support small batches, customized orders, customers can flexibly place orders according to the R&D progress without bearing the cost of mass production.

- Contract machining: Sign long-term cooperation agreements with suppliers, providing one-stop services from design optimization to mass production, suitable for long-term R&D projects.

- Quoting process: Regular suppliers will provide transparent quotations based on factors such as drawing complexity, material costs, and processing cycles, and customers can choose cost-effective solutions through comparison.

5. Yigu Technology's view

As the "touchstone" of industrial innovation, the core value of machined prototypes is to help enterprises avoid risks and optimize design in the early stages of research and development through high-precision and high-performance physical prototypes. Under the current trend of manufacturing industry transforming to intelligence and personalization, the technical iteration of machining prototypes is also accelerating - the application of five-axis machining, AI-assisted programming and other technologies has further improved machining efficiency and accuracy; The development of materials science has also allowed prototypes to better simulate the performance of mass-produced products. Yigu Technology believes that when choosing machining prototype services, enterprises should give priority to the supplier's technical strength, case experience and service response speed, and pay attention to the collaboration between design and manufacturing to maximize the R&D and enabling role of machined prototypes. In the future, with the deepening of Industry 4.0, machining prototypes will be deeply integrated with technologies such as digital twins and virtual testing to provide more efficient solutions for manufacturing innovation.

6. FAQ

- What is the typical lead time for a machined prototype?

Conventional prototypes can be delivered in 3-7 days, and prototypes with complex structures or high-precision requirements can take 10-15 days, depending on the difficulty of processing and material preparation time.

- Does a machined prototype cost more than 3D printing?

The cost of small-batch, simple structural prototypes is higher than 3D printing, but with batches of more than 50 pieces or prototypes that require high precision and strength, machining offers more cost-effectiveness.

- What materials are not suitable for machined prototypes?

Ceramic materials with extremely high hardness and some composite materials with too strong toughness are difficult and costly to process, so they are more suitable for choosing 3D printing or other molding methods.

- Can machined prototypes be used directly for mass production?

Some simple structures and small batch prototypes can be directly used as mass production products, but complex products still need to be adjusted and optimized according to the mass production process.

- How can I ensure that the quality of my machined prototype meets the requirements?

Choose qualified suppliers, clarify quality indicators such as tolerances and surface treatment, and require testing reports, and conduct sampling tests if necessary.