Introduction to Titanium Additive Manufacturing

Titanium additive manufacturing (AM), also known as 3D printing, has rapidly become a transformative force in multiple industries. This advanced process enables the creation of highly complex titanium components with remarkable precision, minimal material waste, and enhanced performance. In this article, we will explore how titanium AM is revolutionizing the aerospace and medical fields by delivering lightweight, durable components and customized biocompatible implants that cater to specific needs.

What Is Titanium Additive Manufacturing?

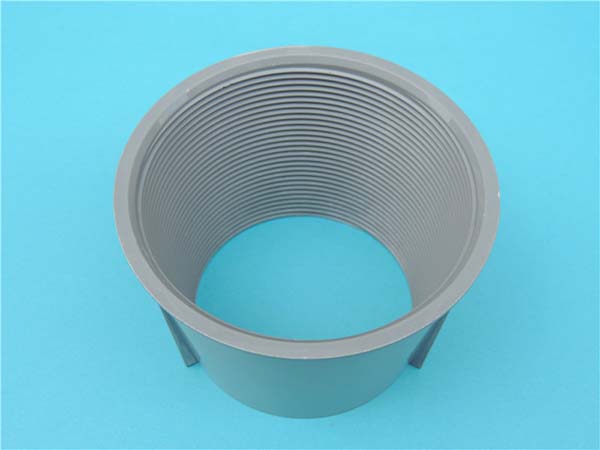

Additive Manufacturing (AM), or 3D printing, is a process where three-dimensional objects are created layer by layer from digital models. Unlike traditional subtractive methods, which involve cutting or shaping raw materials, AM builds objects up, allowing for intricate designs that were previously impossible or impractical to produce.

For titanium applications, the raw material often takes the form of titanium powder, which is precisely melted and fused using high-powered lasers or electron beams. The process starts with a digital design (CAD model) of the part, which is then sliced into thin layers. Specialized machines, such as Selective Laser Sintering (SLS), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS), follow these layers to build the final object.

Historical Development

The concept of additive manufacturing dates back to the 1980s, with Charles Hull’s invention of stereolithography—the first commercial 3D printing technology. However, it wasn’t until the early 2000s that metal AM, specifically titanium AM, began gaining serious traction. Advancements in laser technology, computing power, and materials science have significantly advanced the use of titanium in additive manufacturing, opening doors for applications in high-performance industries like aerospace and healthcare.

Applications in Aerospace

Aircraft Components

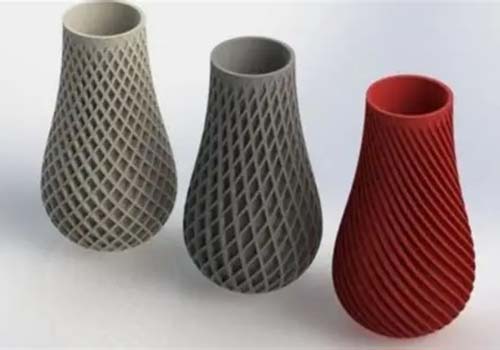

One of the most profound impacts of titanium AM is its ability to address the complex geometries required in modern aircraft manufacturing. Traditional methods struggle with intricate designs that demand high strength while minimizing weight. Titanium AM, on the other hand, allows engineers to produce parts with sophisticated internal structures, such as lattice grids or cooling channels, which can dramatically reduce weight without compromising strength or performance.

For example, turbine blades, fuel nozzles, and other engine components benefit from the precision and efficiency offered by titanium AM. These parts can be engineered to optimize aerodynamics and thermal management, enhancing engine performance and reducing fuel consumption. Additionally, AM's ability to produce near-net-shape parts (those that are close to the final desired shape) reduces the need for extensive post-processing, cutting both time and cost.

Spacecraft and Satellite Parts

Titanium AM is also making significant strides in the manufacturing of satellite and spacecraft components. The harsh conditions of space demand materials that are both incredibly strong and lightweight. Titanium, with its high strength-to-weight ratio and excellent corrosion resistance, is an ideal material for space exploration.

AM allows for the rapid production of complex components like antenna mounts, brackets, and support frames, which are critical for the functionality and reliability of space missions. Moreover, titanium AM enables quick prototyping and design iterations, accelerating the development and deployment of cutting-edge space technologies.

Applications in the Medical Industry

Custom-Made Implants

In the medical sector, titanium AM is revolutionizing the production of custom implants. Traditional manufacturing methods often fall short when it comes to creating implants that perfectly match a patient’s unique anatomical features. Titanium AM overcomes these challenges by allowing for the production of highly personalized implants tailored to an individual’s specific needs.

For example, orthopedic implants like hip replacements, knee joints, and spinal cages benefit from this technology. By using detailed medical imaging data (such as CT scans or MRIs), surgeons and engineers can design implants that offer an exceptional fit, improving patient comfort, implant longevity, and overall surgical outcomes.

Surgical Tools and Instruments

Titanium AM is also transforming the production of surgical tools and instruments. Customized tools, such as surgical guides, scalpels, and forceps, can be designed to enhance precision and ergonomics during medical procedures. These tools are typically lighter and more maneuverable than traditional ones, offering surgeons greater control and reducing fatigue during long operations. Furthermore, these instruments can be tailored to meet the unique needs of different surgeries, improving outcomes for patients.

Advantages of Titanium AM

Material Efficiency

Titanium AM offers a significant advantage in material efficiency. Traditional manufacturing methods often result in high material waste due to cutting, drilling, and machining operations. In contrast, AM uses only the material necessary to create the part, minimizing waste. This not only reduces material costs but also aligns with sustainability goals, helping companies lower their environmental impact.

Design Flexibility

A major advantage of titanium AM is the design freedom it provides. Traditional manufacturing methods are constrained by tooling limitations, but AM allows designers to create complex geometries, internal structures, and optimized shapes that would be impossible with conventional methods. This flexibility fosters innovation and enables engineers to create high-performance parts tailored to specific needs in industries like aerospace and healthcare.

Strength and Durability

Despite being lightweight, parts produced via titanium AM are incredibly strong and durable. The layer-by-layer manufacturing process results in parts with uniform density and minimal porosity, ensuring consistent mechanical properties. Titanium’s inherent properties—such as high tensile strength, fatigue resistance, and biocompatibility—make it ideal for demanding aerospace and medical applications where strength, durability, and performance are critical.

Conclusion

Titanium additive manufacturing is undeniably reshaping the aerospace and medical industries. Its ability to produce highly complex, customized components with minimal waste and maximum performance is driving innovation and improving outcomes across these critical sectors. As the technology continues to evolve, we can expect even greater integration of titanium AM, further enhancing the efficiency, reliability, and sustainability of aerospace and medical solutions.

FAQs

What makes titanium suitable for additive manufacturing?

Titanium is ideal for additive manufacturing due to its excellent mechanical properties, including a high strength-to-weight ratio, corrosion resistance, and biocompatibility. These characteristics make it perfect for aerospace applications where durability and lightweight properties are essential, as well as medical implants where body integration is crucial.

How does titanium additive manufacturing compare to traditional manufacturing methods?

Compared to traditional manufacturing, titanium AM offers several key advantages:

- Complexity: AM allows the production of intricate geometries that are often impossible or prohibitively expensive to achieve with conventional methods.

- Material Efficiency: AM reduces material waste by using only the amount of raw material necessary to create the part.

- Customization: AM enables the creation of highly customized parts tailored to specific applications, improving performance and fit.

- Speed: The rapid prototyping capabilities of AM accelerate the design and development process, reducing time-to-market.

- Cost-Effectiveness: Although AM equipment can have high initial costs, the reduction in material waste and streamlined production can lead to long-term savings.

Are there limitations or challenges with titanium additive manufacturing?

While titanium AM offers numerous benefits, there are some challenges to consider:

- Cost: The initial setup costs for AM equipment and titanium powders can be high, making it less accessible for smaller businesses.

- Quality Control: Ensuring consistent quality across parts requires careful monitoring and testing.

- Post-Processing: Some AM parts may need additional post-processing (e.g., heat treatment or machining) to achieve the desired surface finish or dimensional tolerance.

- Material Variability: Differences in titanium powder batches can affect the final product, requiring quality control measures during production.

- Regulatory Compliance: In the medical field, products must meet strict regulatory standards to ensure safety and efficacy.

Despite these challenges, ongoing advancements in AM technology are continually improving its capabilities, making titanium AM a powerful tool for the future of aerospace and medical manufacturing.