Introduction to Precision Machining Group

In a world where precision is not just desired but required, the Precision Machining Group (PMG) stands as a premier provider of high-precision machining services. Renowned for their ability to meet the most demanding tolerances, PMG has become a trusted partner across industries where every micron counts. From aerospace to medical devices, automotive to electronics, the group’s commitment to excellence and continuous innovation has enabled them to remain at the forefront of high-precision manufacturing.

This article delves into the history, values, capabilities, and technologies that underpin PMG’s success, highlighting the essential role they play in shaping the future of manufacturing.

Background and Core Values of the Group

Historical Context

Founded in [Year], the Precision Machining Group began as a small, local workshop, offering custom machining solutions for regional businesses. Over the years, the company’s commitment to quality and precision, coupled with strategic investments in cutting-edge technologies, enabled PMG to expand into a global player in high-precision manufacturing. Today, PMG is recognized worldwide for its exceptional ability to meet exacting tolerances across a variety of industries.

Core Values

- Precision and Quality: PMG has built its reputation on the ability to produce components with ultra-tight tolerances. Their quality control systems ensure that each part is produced to the highest standards, consistently meeting the most stringent industry specifications.

- Customer-Centric Approach: Every project begins with a deep understanding of the customer’s needs. PMG collaborates closely with clients, providing tailored solutions and ensuring that every aspect of production is optimized for efficiency, cost-effectiveness, and performance.

- Innovation: The manufacturing industry is constantly evolving, and so is PMG. Through continuous research and development, the group integrates the latest technological advancements and process improvements into its operations, ensuring they stay ahead of industry trends.

- Sustainability: Recognizing the importance of environmental responsibility, PMG adopts sustainable practices, from reducing waste to optimizing resource usage. This not only helps the environment but also improves efficiency and cost savings for clients.

Expertise and Services

Overview of Precision Machining Capabilities

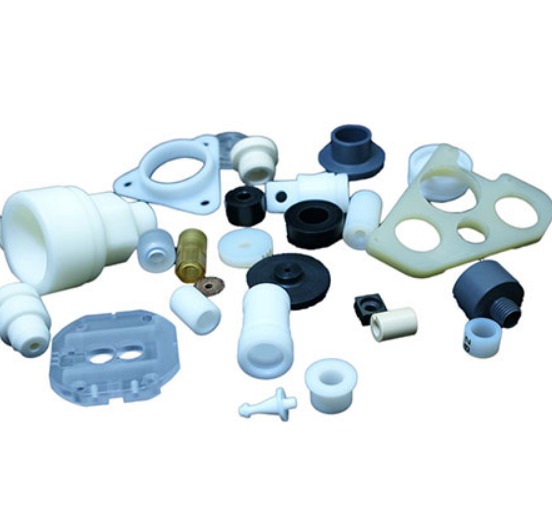

PMG offers a broad range of precision machining services designed to meet the diverse needs of its global clientele. These services include:

- CNC Milling: Using advanced CNC machines, PMG can produce components with complex geometries, ensuring high accuracy and repeatability.

- CNC Turning: Ideal for cylindrical parts, CNC turning allows for precise control over dimensions and surface finishes.

- EDM (Electrical Discharge Machining): A technique used for machining hard metals and intricate designs that are difficult to machine with traditional methods.

- Wire EDM: Allows for extremely precise cuts in hard materials, enabling the production of delicate parts with tight tolerances.

- Surface Grinding: Used for fine-tuning surface finishes and achieving tight flatness tolerances.

- Multi-Axis Machining: For producing parts with complex shapes and geometries in a single setup, reducing lead times and ensuring consistency.

Each of these services is performed using state-of-the-art equipment and technologies, ensuring that every part is made to the highest standards of precision.

Custom Machining Solutions

One of PMG’s core strengths is their ability to handle custom machining projects. Whether it’s producing a one-off prototype or fulfilling a high-volume production run, PMG is equipped to handle even the most complex and demanding machining tasks. Their skilled engineers and technicians work with clients at every stage of the process, from design to production, ensuring that each component perfectly aligns with the client’s specific requirements.

Industries Served

PMG caters to a wide range of industries, each with unique demands for precision and quality. Below are some of the key sectors served by the group:

Aerospace

In aerospace, even the smallest defect can have catastrophic consequences. PMG is trusted by aerospace companies to produce engine components, landing gear parts, and other critical systems that must adhere to the strictest tolerances. With specialized expertise and advanced machining capabilities, PMG delivers parts that contribute to the safety, performance, and reliability of aircraft.

Automotive

The automotive industry demands both high performance and high precision. Whether it’s components for high-performance sports cars or parts for mass-market vehicles, PMG ensures that every part meets the required specifications. By using precision machining, PMG helps automotive manufacturers enhance vehicle performance, efficiency, and durability.

Medical

In the medical field, precision can make all the difference between life and death. PMG produces surgical instruments, implants, and other medical devices that must be crafted with micron-level accuracy. The ability to manufacture critical medical components with extreme precision ensures patient safety and effective treatment.

Electronics

As electronics become increasingly miniaturized, the need for precise machining grows. PMG manufactures components for smartphones, computers, and other electronic devices, where precision is essential to ensuring each part fits seamlessly into modern gadgets’ complex, high-density designs.

Industry-Specific Precision Requirements

Each industry served by PMG has unique precision requirements:

- Aerospace: Tolerances as tight as ±0.001 inches to ensure safety and performance.

- Medical: Surgical instruments may require tolerances as tight as ±0.0001 inches to ensure precision and reliability.

- Automotive: Automotive engine components may require tolerances of ±0.005 inches to meet performance and durability standards.

- Electronics: Miniature electronic components often require tolerances within ±0.0005 inches for seamless integration into devices.

PMG’s ability to meet these varying tolerance requirements, regardless of the industry, makes them a go-to provider for precision machining.

Technology and Equipment

State-of-the-Art Machining Centers

PMG operates some of the most advanced machining centers in the world. The company uses high-precision CNC machines and multi-axis machining systems that allow for the manufacturing of complex parts in a single setup. This minimizes setup times, enhances accuracy, and ensures that every part is machined to exacting standards.

Quality Control and Inspection Equipment

To guarantee the highest levels of precision, PMG employs advanced quality control systems, including:

- Coordinate Measuring Machines (CMM): For detailed measurement of part dimensions and ensuring they meet tight tolerances.

- Laser Scanning Systems: Used for quick and accurate dimensional analysis.

- Optical Comparators: For inspecting intricate features and ensuring correct geometry.

- Microscopes and Magnifying Lenses: For final visual inspection, ensuring the quality of each part.

These advanced tools allow PMG to conduct detailed inspections at various stages of the manufacturing process, ensuring that every part meets the required specifications before it leaves the facility.

Precision and Tolerance

Achieving ultra-precision standards is critical in high-tolerance manufacturing. PMG’s combination of advanced technology, highly skilled labor, and rigorous quality control measures ensures that they deliver parts with exceptional precision. Even the slightest deviation can compromise the performance of critical components, which is why PMG’s commitment to quality is paramount.

Tolerance Levels and Their Importance

Tolerance levels indicate the allowable deviation from a specified dimension. In high-precision industries, even tiny deviations can result in severe consequences:

- Performance: In aerospace and automotive, small tolerance deviations can drastically impact component performance and safety.

- Fit and Function: Tight tolerances ensure that parts fit together perfectly, preventing malfunction or failure.

- Durability: Precision machining increases the lifespan of components, reducing wear and tear and maintenance costs.

- Cost Efficiency: While achieving tight tolerances can be more expensive initially, it often results in fewer errors, reducing costs related to rework and scrap material.

Case Studies and Success Stories

Examples of Precision Machining Projects

Aerospace: Turbine Blade Redesign

PMG worked with a leading aerospace manufacturer to redesign turbine blades for a more fuel-efficient engine. The project required tight tolerances to improve aerodynamics and reduce emissions. Using advanced CNC milling and EDM techniques, PMG delivered blades that not only met the client’s strict specifications but also contributed to performance improvements.

Medical: Custom Surgical Instruments

PMG produced custom surgical instruments for a medical device company specializing in minimally invasive procedures. The instruments required tolerances of ±0.0001 inches, ensuring they could navigate delicate anatomical structures with precision. The success of the project led to PMG becoming a trusted supplier for the client’s entire line of medical devices.

Automotive: High-Performance Engine Parts

For a luxury car manufacturer, PMG produced high-performance engine components that required tolerances within ±0.005 inches to ensure optimal engine performance and longevity. The components passed rigorous testing, and the final parts contributed to enhanced vehicle performance and reliability.

Conclusion: The Role of Precision Machining Group in Modern Manufacturing

The Precision Machining Group plays an integral role in shaping the future of modern manufacturing. Through a commitment to precision, quality, and innovation, PMG continues to set the standard for high-tolerance machining. By embracing cutting-edge technology, maintaining a customer-centric approach, and fostering continuous improvement, PMG has established itself as a key partner in industries where precision is paramount.

As the demands for ultra-precision manufacturing continue to grow, PMG remains at the forefront, driving innovation and ensuring that industries worldwide can rely on their expertise to meet the ever-increasing demands for high-quality, high-precision components.