From aerospace components needing microscale cooling channels to jewelry requiring intricate designs, industries demand surface treatments that combine precision, durability, and customization. Traditional methods like stamping or machining often fall short—they struggle with fine details, damage delicate materials, or can’t replicate complex patterns on curved surfaces. A medical device might need a serial number etched to track sterilization cycles, or a circuit board could require precise conductive pathways—tasks that demand accuracy down to 0.01 mm. This is where surface treatment etching & engraving excels. By selectively removing material to create patterns, text, or textures, these processes deliver unmatched detail, consistency, and versatility—solving these critical challenges across industries. In this guide, we’ll explore how etching and engraving work, their key types, properties, and how they transform surfaces for both function and aesthetics.

Introduction to Etching & Engraving

Etching & engraving are surface treatments that remove material to create intentional patterns, with subtle differences in technique but overlapping goals:

- Definition: Etching uses chemicals, lasers, or abrasives to dissolve or ablate material, while engraving uses mechanical tools or lasers to cut into the surface. Both processes create recessed designs, but etching is often more suitable for fine details, and engraving for deeper, more tactile patterns.

- Historical background: Engraving dates to ancient civilizations, with metalworkers using chisels to decorate weapons and jewelry. Etching emerged in the 15th century when artists discovered acid could bite into metal covered by wax designs. The Industrial Revolution mechanized these processes, and today, lasers and CNC systems enable microscale precision.

- Basic principles: Both processes follow three steps: (1) defining the pattern (via masks, digital files, or stencils), (2) removing material (chemically, mechanically, or with lasers), and (3) finishing (cleaning, deburring, or coating). The key is selective material removal—protecting areas to keep while removing others to create the design.

- Industrial significance: The global etching & engraving market exceeds $5 billion, driven by demand for part traceability (aerospace, medical), decorative finishes (jewelry, consumer goods), and functional patterns (heat sinks, anti-slip textures). Laser etching alone grows at 7% annually, thanks to its precision in electronics and automotive applications.

- Environmental considerations: Modern processes prioritize sustainability—chemical etching uses recyclable acids (e.g., ferric chloride) with closed-loop filtration, while laser systems consume minimal energy. Mechanical engraving recycles metal shavings, and water-based cleaning replaces toxic solvents, complying with EPA and REACH standards.

- Comparison with other surface treatments: Etching & engraving offer unique pattern control:

| Feature | Etching (Chemical/Laser) | Engraving (Mechanical/CNC) | Stamping |

|---|---|---|---|

| Detail Resolution | 0.01-0.1 mm | 0.05-0.5 mm | 0.5-2 mm |

| Material Compatibility | Metals, glass, polymers | Metals, wood, stone | Metals (thick, rigid) |

| Depth Control | 0.001-0.5 mm | 0.1-5 mm | 0.5-10 mm |

| Curved Surface Ability | Excellent | Good (with CNC) | Poor |

Types of Etching & Engraving

These processes vary by tool and method, each suited to specific materials and design needs:

- Chemical etching: Uses acidic or caustic solutions (ferric chloride, nitric acid) to dissolve unprotected areas. Ideal for thin metals (0.01-1 mm thick) and complex patterns—medical stents with 0.1 mm holes or electronics with microchannels. It’s cost-effective for high-volume runs and leaves no burrs.

- Photochemical etching: Combines photography and chemical etching—photosensitive film (photoresist) is exposed to UV light through a pattern mask, then developed to protect areas from etching. It achieves 0.01 mm resolution, used for semiconductor lead frames and precision filters.

- Laser etching: Uses a focused laser beam (CO₂, fiber) to ablate material, creating precise patterns without contact. Fiber lasers excel at metals (engraving serial numbers), while CO₂ lasers work on polymers and glass. It’s fast (up to 10,000 mm/min) and ideal for small batches or variable designs.

- Mechanical engraving: Uses rotating cutters or diamond tips to carve into surfaces, creating deep, tactile patterns. CNC engraving machines follow digital files, ensuring consistency across batches. Used for signs, dies, and metal molds where depth (0.5-5 mm) and durability matter.

- Electrochemical etching: Uses an electric current to dissolve material in a conductive solution, similar to reverse plating. It’s gentle on thin materials, used for etching on fragile parts like aerospace turbine blades without causing stress.

- Sandblast etching: Blasts abrasive particles (aluminum oxide) at high pressure to erode unprotected areas, creating frosted or textured finishes. Common on glass (windows, awards) and stone, where a matte pattern contrasts with a smooth surface.

- Hand engraving: Artisans use gravers and chisels to create custom designs, valued for their uniqueness in jewelry, firearms, and luxury goods. It offers artistic flexibility but lacks the consistency of automated methods.

Properties of Etched & Engraved Surfaces

The properties of etched & engraved surfaces are tailored to both functional and aesthetic needs:

- Detail resolution: Chemical and laser etching achieve 0.01-0.1 mm line widths, with photochemical etching reproducing features as small as 5 μm—critical for microfluidic devices and circuit boards. Mechanical engraving handles 0.05-0.5 mm details, balancing precision with depth.

- Dimensional accuracy: CNC and laser systems control depth within ±0.001 mm, ensuring patterns align with tolerances in aerospace parts (e.g., 0.1 mm deep cooling channels with ±0.01 mm variance). This precision prevents performance issues in functional components.

- Surface finish: Etched surfaces are often smoother (Ra 0.1-0.5 μm) than engraved ones (Ra 0.5-2 μm) because chemical or laser processes avoid mechanical tool marks. This is vital for medical devices, where smoothness reduces bacterial adhesion.

- Depth control: Etching typically removes 0.001-0.5 mm, suitable for thin films or decorative patterns, while engraving can go 0.1-5 mm deep—ideal for creating grooves in tooling or raised lettering on signs.

- Adhesion: Etched textures (e.g., micro-grooves) improve coating adhesion by 30-50% compared to smooth surfaces, as the pattern creates mechanical interlocks. This is used in automotive parts where paint or plating must withstand wear.

- Corrosion resistance: When done properly (removing all etchant residues), etched surfaces resist corrosion as well as unprocessed material. For example, passivated stainless steel etched parts survive 5000+ hours of salt spray testing (ASTM B117).

- Aesthetic appeal: Engraved patterns have a tactile, 3D quality (e.g., jewelry with 0.5 mm deep designs), while etched patterns offer subtlety (e.g., matte logos on smartphone backs). Both can be colored (via oxidation or plating) to enhance contrast.

Applications of Etching & Engraving

These processes solve diverse challenges across industries, from functionality to branding:

- Aerospace: Laser etching marks turbine blades with part numbers for traceability, while chemical etching creates microscale cooling holes (0.5 mm diameter) in engine components to prevent overheating. Electrochemical etching adds anti-icing textures to wing surfaces.

- Medical devices: Photochemical etching produces precision meshes for implants (e.g., hernia patches) with 0.1 mm pores. Laser engraving adds unique identifiers to surgical tools, enabling tracking through sterilization cycles—required by FDA regulations.

- Electronics: Chemical etching creates conductive pathways on flexible circuits (e.g., smartwatch bands) with 0.1 mm line widths. Laser etching trims resistors to exact values, ensuring circuit accuracy.

- Jewelry: Hand engraving adds intricate patterns to gold and silver pieces, while laser etching creates detailed designs on titanium or stainless steel. Sandblast etching textures watch cases for a premium look.

- Automotive: CNC engraving adds VIN numbers to engine blocks, while chemical etching creates anti-glare textures on instrument panels. Laser etching marks tires with DOT codes for safety compliance.

- Signage: Mechanical engraving produces durable metal signs (e.g., building plaques) with 1 mm deep lettering, while sandblast etching creates frosted glass signs for offices and restaurants.

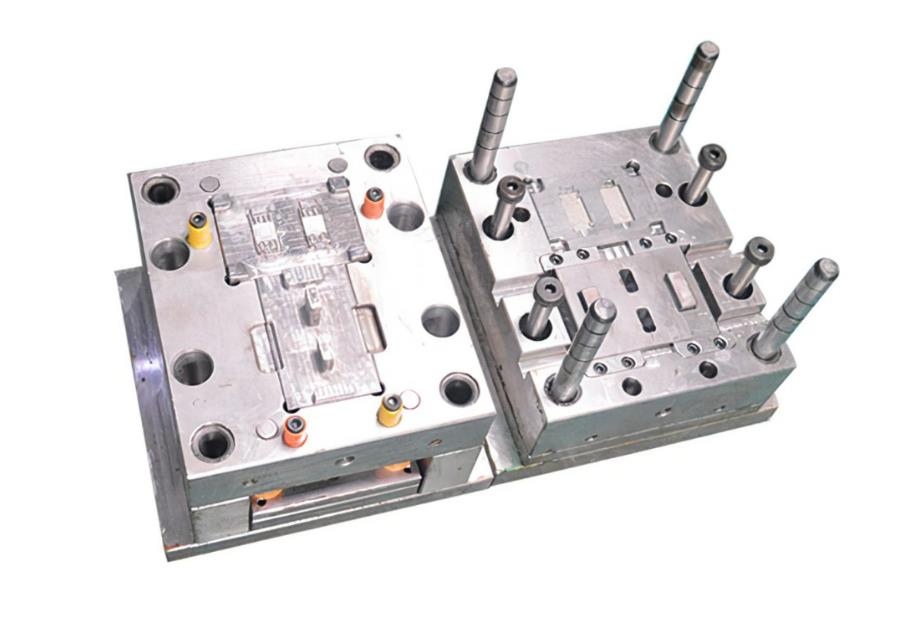

- Tooling: Engraved molds for plastic injection have precision cavities (±0.01 mm) that replicate textures onto consumer goods (e.g., smartphone buttons with grip patterns). Etched dies stamp consistent designs onto metal parts.

Etching & Engraving Process and Equipment

The etching & engraving process and equipment vary by method but share core steps:

- Etching tanks: Chemical etching uses polypropylene or PVC tanks (10-1000 liters) with heated solutions (40-60°C) for consistent etching. Agitation systems (air or mechanical) ensure uniform contact between chemical and substrate.

- Laser etching machines: Fiber lasers (1064 nm wavelength) for metals, CO₂ lasers (10.6 μm) for non-metals, and UV lasers (355 nm) for high-resolution work on glass. Power ranges from 10-1000 W, with beam diameters as small as 10 μm.

- CNC engraving machines: Computer-controlled routers with spindles (10,000-60,000 RPM) and interchangeable tools (carbide, diamond). They follow CAD files, achieving positional accuracy of ±0.002 mm—critical for alignment in 模具 (molds).

- Photoresist materials: Light-sensitive films or liquids (dry film, liquid resist) used in photochemical etching. They’re applied via lamination or spraying, then exposed to UV light through a mask to define protected areas.

- Chemical solutions: Ferric chloride (for copper, steel), nitric acid (for aluminum), and hydrofluoric acid (for glass) are common etchants. Concentration (10-40%) and temperature control etch rate (0.01-0.1 mm/min).

- Pre-treatment processes: Substrates are degreased (alkaline cleaners) and polished to remove oxides, ensuring uniform etching. Masking (tape, photoresist, or stencils) protects areas not being processed.

- Post-treatment processes: Etched parts are rinsed (water, neutralizing agents like baking soda) to stop chemical reactions. Deburring (electropolishing, abrasive blasting) removes sharp edges, and coatings (paint, powder) can fill recessed areas for contrast.

- Safety equipment: Chemical-resistant gloves, goggles, and fume hoods for etchants; laser safety glasses (specific to wavelength); and dust collectors for mechanical engraving to protect operators and air quality.

Quality Control and Maintenance in Etching & Engraving

Rigorous protocols ensure patterns meet design specs and process reliability:

- Dimensional inspection: Optical comparators and coordinate measuring machines (CMM) verify pattern dimensions (line width, spacing) within ±0.005 mm. For microscale features, scanning electron microscopy (SEM) checks accuracy.

- Depth measurement: Profilometers and depth gauges confirm etch/engraving depth, with tolerances as tight as ±0.001 mm for aerospace components. Laser confocal microscopy maps 3D surface profiles for complex patterns.

- Adhesion testing: For masked areas, tape tests (ASTM D3359) ensure resist or masking materials don’t lift during processing, preventing undercutting or uneven patterns.

- Defect detection: Visual inspection under 10-50x magnification identifies issues like incomplete etching (resist residues), over-etching (pattern distortion), or tool marks in engraving. Automated vision systems check high-volume parts at 1000+ units/hour.

- Equipment maintenance: Laser lenses are cleaned daily to prevent beam distortion, and CNC tool changers are calibrated weekly for positional accuracy. Chemical etching tanks are stripped and re-lined every 6-12 months to prevent corrosion.

- Process control: Etch time, temperature, and chemical concentration are logged for each batch. For laser etching, power and speed are monitored (±5% tolerance) to ensure consistent ablation.

- Quality standards: Compliance with ISO 9001 (general manufacturing), ISO 13485 (medical devices), and ASTM B809 (chemical etching of metals) ensures reliability. Aerospace parts meet AS9100 for traceability and performance.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology offers precision etching & engraving services for aerospace, medical, and electronics industries. Our capabilities include photochemical etching (0.01 mm detail), fiber laser engraving (metals), and CNC mechanical engraving. We handle materials from stainless steel and aluminum to polymers and glass, with strict quality checks via CMM and optical inspection. Our processes use eco-friendly etchants and energy-efficient lasers, complying with ISO 9001 and medical ISO 13485. Whether creating microchannels for sensors or serial numbers for traceability, we deliver consistent, on-time results tailored to client specs—balancing precision with cost-effectiveness.

FAQs

- Can etching or engraving be done on curved surfaces?

Yes—laser etching and electrochemical etching work well on curved surfaces because they don’t require mechanical contact. For example, laser systems can engrave serial numbers on cylindrical aerospace parts or curved smartphone cases with ±0.01 mm accuracy. - Which process is better for high-volume production?

Chemical etching and photochemical etching excel at high volumes (10,000+ parts) because masks are reusable, and processing is batch-based. Laser etching is faster for small batches (1-1000 parts) due to quick setup, while mechanical engraving is best for medium runs requiring deep patterns. - How durable are etched or engraved patterns?

Both processes create permanent patterns—chemical etching bonds with the material’s structure, and engraving cuts below the surface, so designs resist wear, fading, or peeling. In automotive tests, laser-etched VINs survive 10+ years of weathering and cleaning without degradation.