Introduction

The Significance of CNC Precision Machined Components

In the modern manufacturing landscape, CNC (Computer Numerical Control) precision machined components stand as the cornerstone of innovation and efficiency. These components play a pivotal role across a diverse range of industries, revolutionizing the way products are designed, produced, and ultimately, enhancing the quality of life.

Aerospace Industry

In the aerospace sector, precision is not just a preference; it's a necessity. Aircraft and spacecraft operate in extreme conditions, where the slightest deviation can lead to catastrophic consequences. CNC precision machined components are used in the manufacturing of critical parts such as engine components, wings, and fuselage structures. For Yigu Technology example, high - precision CNC - machined turbine blades in jet engines need to withstand temperatures of up to 1,700°C while maintaining their structural integrity. These components are made from advanced materials like superalloys and titanium alloys, and the precision of CNC machining ensures that they fit together perfectly, optimizing engine performance and fuel efficiency. According to industry reports, the use of CNC - machined components in aerospace has led to a 15 - 20% reduction in fuel consumption for commercial aircraft, a significant factor considering the high cost of aviation fuel and the industry's focus on sustainability.

Automotive Industry

The automotive industry has also been greatly transformed by CNC precision machining. From engine blocks to transmission gears, CNC - machined components are integral to the performance, safety, and reliability of vehicles. For instance, the engine cylinder heads, which are complex components with multiple ports and passages, are now produced with high precision using CNC machining. This results in better fuel - air mixing, improved combustion efficiency, and reduced emissions. A study by an automotive research institute showed that vehicles with CNC - machined engine components had a 10 - 15% increase in fuel efficiency compared to those with conventionally - made components. Additionally, CNC machining enables the production of lightweight components, contributing to overall vehicle weight reduction. Lighter vehicles require less energy to move, further improving fuel economy and reducing emissions.

Medical Industry

In the medical field, CNC precision machined components are crucial for the production of life - saving and life - enhancing devices. Components for surgical instruments, implants, and diagnostic equipment are all produced with high precision. Take hip implants as an example. These implants need to be a perfect fit for the patient's anatomy to ensure long - term functionality and comfort. CNC machining allows for the creation of implants with extremely tight tolerances, typically within ±0.05mm. This high level of precision ensures that the implant integrates well with the patient's bone structure, reducing the risk of rejection and improving the success rate of surgeries. Moreover, for complex medical devices like MRI and CT scanners, CNC - machined components ensure the accurate alignment of various parts, which is essential for high - quality imaging and accurate diagnosis.

Current State of CNC Precision Machined Components

Common Applications

CNC precision machined components are ubiquitous in modern manufacturing, finding applications in a plethora of industries, each with its own set of requirements.

Aerospace: As mentioned before, in the aerospace industry, components need to be extremely precise. Tolerances are often within the range of ±0.01mm - ±0.001mm. For Yigu Technology example, in the production of aircraft engine turbine blades, not only must the dimensions be exact, but the surface finish also has to be of the highest quality to reduce air resistance and improve fuel efficiency. The materials used, such as nickel - based superalloys, are difficult to machine, and the complex shapes of the blades demand high - precision CNC machining techniques.

Automotive: In the automotive sector, components like engine blocks and transmission gears are made with high precision. Engine blocks need to have precise cylinder bores to ensure proper piston fit. The tolerance for cylinder bore diameter in a high - performance engine can be as tight as ±0.03mm - ±0.05mm. CNC - machined transmission gears must have accurate tooth profiles to minimize noise, vibration, and power loss during operation.

Medical: In medical applications, components for implants and surgical instruments require top - notch precision. Dental implants, for instance, need to match the patient's jawbone structure precisely. The diameter and thread pitch of dental implants typically have a tolerance of ±0.02mm - ±0.03mm. Surgical instruments, such as forceps and scalpels, also need to be precisely machined to ensure accurate and safe procedures.

Electronics: For electronic devices, components are getting smaller and more precise. In the manufacturing of printed circuit board (PCB) connectors, the pin pitch can be as small as 0.4mm - 0.5mm, and the position accuracy of the pins must be within a few micrometers. Heat sinks for high - performance CPUs are also CNC - machined to have precise fins for efficient heat dissipation.

Existing Technologies and Processes

Milling

- 3 - Axis Milling: This is the most basic form of CNC milling. It involves the movement of the cutting tool along three linear axes (X, Y, and Z). 3 - axis milling is suitable for machining simple 2D and 2.5D parts. For Yigu Technology example, it can be used to mill flat surfaces, slots, and pockets. The advantage of 3 - axis milling is its relatively low cost, both in terms of equipment and programming complexity. However, its limitation is that it can only machine parts from one side at a time, and complex 3D shapes are difficult to achieve without multiple setups.

- 4 - Axis Milling: In addition to the three linear axes, 4 - axis milling adds a rotary axis (usually denoted as A, B, or C). This allows the workpiece to be rotated while being machined, enabling the creation of more complex shapes. For example, it can be used to mill tapered holes or helical grooves. The main advantage of 4 - axis milling over 3 - axis is the ability to reduce the number of setups for complex parts, which can improve accuracy by minimizing errors introduced during re - positioning. But it is more expensive than 3 - axis milling in terms of equipment cost and requires more skilled operators.

- 5 - Axis Milling: 5 - axis milling offers the highest degree of freedom in machining, with three linear axes and two rotary axes. It can machine complex 3D shapes in a single setup, such as the impellers in turbochargers or the complex surfaces of aerospace components. 5 - axis milling can improve machining efficiency, reduce cycle times, and enhance surface quality. However, it is the most expensive in terms of equipment purchase, maintenance, and programming. The complexity of programming for 5 - axis machines requires highly skilled engineers to ensure that the toolpaths are optimized and collisions are avoided.

Turning

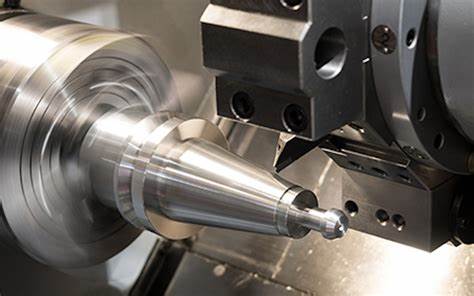

Turning is another fundamental CNC machining process. It involves rotating the workpiece while a cutting tool removes material to create a cylindrical or conical shape. There are several types of turning operations:

- CNC Lathe Turning: This is the basic form of turning, used for creating simple cylindrical parts like shafts and bushings. The workpiece rotates on a spindle, and the cutting tool moves along the X and Z axes (in a two - axis lathe) to shape the part. CNC lathes can achieve high - precision machining, with dimensional tolerances as low as ±0.01mm. The advantage of CNC lathe turning is its high accuracy for cylindrical parts and its relatively fast production speed for simple geometries. However, it is limited to parts with rotational symmetry.

- Swiss - Type Turning: Swiss - type lathes are specialized for machining small, precision components. They are equipped with a guide bushing that supports the workpiece close to the cutting point, which reduces vibration and enables high - precision machining of long, slender parts. Swiss - type turning is commonly used in the production of components for watches, medical devices, and electronics. It can achieve extremely tight tolerances, often within the range of ±0.002mm - ±0.005mm. But Swiss - type lathes are more expensive than standard CNC lathes and have a more complex setup process.

A comparison of some of these common CNC machining processes is shown in the following Yigu Technology table:

| Machining Process | Complexity of Shapes | Accuracy (Typical Tolerance) | Cost of Equipment | Programming Complexity |

| 3 - Axis Milling | Limited to 2D and 2.5D | ±0.05mm - ±0.1mm | Low - Medium | Low |

| 4 - Axis Milling | More complex than 3 - axis, can do some 3D features | ±0.03mm - ±0.05mm | Medium - High | Medium |

| 5 - Axis Milling | Complex 3D shapes | ±0.01mm - ±0.03mm | High | High |

| CNC Lathe Turning | Cylindrical and conical shapes | ±0.01mm - ±0.03mm | Medium | Medium |

| Swiss - Type Turning | Small, high - precision components with rotational symmetry | ±0.002mm - ±0.005mm | High | High |

Key Factors Driving Innovation

Technological Advancements

New Materials

The development and application of new materials are revolutionizing CNC precision machining. For Yigu Technology example, in the aerospace industry, the use of advanced composite materials such as carbon - fiber - reinforced polymers (CFRPs) has become increasingly common. CFRPs offer a high strength - to - weight ratio, which is crucial for reducing the weight of aircraft and improving fuel efficiency. However, machining CFRPs is more challenging compared to traditional metals. The fibrous nature of CFRPs can cause issues such as fiber pull - out, delamination, and tool wear. Specialized cutting tools and optimized machining parameters are required. For instance, diamond - coated tools are often used to cut CFRPs, and lower cutting speeds and higher feed rates are typically employed to minimize damage to the composite structure.

In the medical field, biocompatible materials like titanium - based alloys and some ceramics are being widely used for implants. Titanium alloys, such as Ti - 6Al - 4V, are popular due to their excellent biocompatibility, corrosion resistance, and mechanical properties. Machining titanium alloys is difficult because they have a low thermal conductivity, which can lead to high temperatures at the cutting edge, causing rapid tool wear. To address this, advanced cooling techniques and high - performance cutting tools made of materials like cubic boron nitride (CBN) are used.

A comparison of the machining difficulties and performance advantages of some common materials in CNC precision machining is shown in the following Yigu Technology table:

| Material | Machining Difficulty | Performance Advantages |

| Aluminum Alloys | Relatively low. Low cutting forces, easy to machine, and good surface finish can be achieved. | Lightweight, good corrosion resistance, and high thermal conductivity. |

| Steel (e.g., Stainless Steel) | Moderate. Higher cutting forces are required, and tool wear can be an issue, especially for high - strength steels. | High strength, good toughness, and corrosion resistance in the case of stainless steel. |

| Titanium Alloys | High. Low thermal conductivity leads to high cutting temperatures and rapid tool wear. | Excellent biocompatibility, high strength - to - weight ratio, and good corrosion resistance. |

| Carbon - Fiber - Reinforced Polymers (CFRPs) | High. Prone to fiber pull - out, delamination, and tool wear. | High strength - to - weight ratio, low density, and good fatigue resistance. |

Advanced Machinery and Equipment

Advanced CNC machining equipment is a cornerstone of innovation in the field. High - precision machine tools, such as five - axis machining centers, have significantly enhanced the capabilities of CNC precision machining. These machines can perform complex operations in a single setup, reducing errors associated with multiple setups and improving overall accuracy.

For example, a study by a leading machine tool manufacturer found that when using a five - axis CNC machining center to produce aerospace components, the dimensional accuracy could be improved by up to 50% compared to traditional three - axis machining. The surface roughness of the machined parts also decreased by approximately 30%, resulting in better - quality components. In terms of efficiency, five - axis machining centers can reduce the machining time by 30 - 40% for complex parts. This is because they can access multiple surfaces of the workpiece without re - positioning, enabling more continuous and efficient machining operations.

Another example is the use of high - speed spindles in CNC machining. High - speed spindles can rotate at speeds of up to 100,000 revolutions per minute (RPM) or even higher in some advanced models. When machining aluminum alloys with a high - speed spindle, the material removal rate can be increased by 2 - 3 times compared to conventional spindles. This not only improves production efficiency but also reduces the cutting forces and heat generated during machining, which is beneficial for achieving better surface quality and dimensional accuracy.

Industry Demands

Higher Precision Requirements

In industries such as aerospace and medical, the demand for ever - higher precision in CNC precision machined components is unrelenting.

In aerospace, the trend towards more fuel - efficient and reliable aircraft has led to extremely tight tolerances for components. For engine components, tolerances are now often in the sub - micrometer range. A study by an aerospace research organization showed that reducing the tolerance of turbine blade airfoils from ±0.05mm to ±0.01mm can improve engine efficiency by 2 - 3%. This small reduction in tolerance requires advanced CNC machining techniques, such as ultra - precision grinding and high - speed milling with nanometer - level control.

In the medical industry, the development of minimally invasive surgical procedures and personalized medicine has increased the need for highly precise components. For example, in the production of custom - made orthopedic implants, the components need to match the patient's unique anatomy precisely. A deviation of even ±0.1mm in the implant's dimensions can lead to discomfort, reduced functionality, or even the failure of the implant. Advanced CNC machining, combined with 3D scanning and computer - aided design (CAD), enables the production of implants with tolerances as low as ±0.02mm, ensuring a better fit and improved patient outcomes.

Cost - Efficiency

Cost - efficiency is a major concern for all industries, and innovation in CNC precision machining plays a crucial role in achieving this goal. One way to reduce costs is through the optimization of the machining process to minimize material waste. A manufacturing company implemented a new process planning system for CNC machining. By using advanced software to simulate the machining process and optimize the toolpaths, they were able to reduce material waste by 15 - 20%. For example, in the production of aluminum alloy parts, the new process planning system reduced the amount of excess material that needed to be removed, saving both material costs and machining time.

Another aspect is the reduction of energy consumption. Newer CNC machines are being designed with energy - efficient features. For instance, some modern CNC lathes are equipped with intelligent power management systems that can adjust the power consumption according to the machining load. A case study showed that these energy - efficient CNC lathes can reduce energy consumption by 20 - 30% compared to older models, resulting in significant cost savings over the long term. Additionally, the use of high - performance cutting tools that can maintain their sharpness for longer periods reduces the frequency of tool replacements, further cutting down on costs.

Case Studies of Innovation Success

In the Aerospace Industry

Consider a leading aerospace company that was facing challenges in manufacturing a new generation of aircraft engine components. These components needed to be lighter, stronger, and more fuel - efficient to meet the industry's growing demands for sustainability and performance.

The company turned to innovative CNC precision machining techniques. They adopted a combination of high - speed milling and electrochemical machining (ECM). High - speed milling allowed for the rapid removal of material while maintaining high precision. The use of advanced cutting tools with specialized coatings reduced tool wear and improved the surface finish of the components.

For complex internal geometries, such as the cooling channels in turbine blades, they employed ECM. ECM is a non - traditional machining process that uses an electrolyte solution and an electric current to dissolve metal atoms from the workpiece, creating the desired shape. This process is particularly useful for creating intricate shapes in hard - to - machine materials without generating heat - affected zones or mechanical stresses.

As a result of these innovative machining methods, the company achieved a 20% reduction in the weight of the engine components. The improved precision of the components led to a 15% increase in engine efficiency, translating to significant fuel savings over the lifespan of the aircraft. Additionally, the use of ECM reduced the need for secondary finishing operations, saving both time and cost in the production process.

In the Medical Device Field

A well - known medical device manufacturer was aiming to develop a new, more accurate and patient - friendly spinal implant system. The challenge was to create implants that could fit precisely into the patient's unique spinal anatomy while maintaining high strength and biocompatibility.

The company utilized a combination of 3D scanning, CAD/CAM technology, and multi - axis CNC machining. First, they used 3D scanning to create a detailed digital model of the patient's spine. This model was then imported into CAD software, where engineers designed the implant to perfectly match the patient's anatomy.

The CAD model was transferred to CAM software, which generated the CNC machining instructions. The manufacturer used a five - axis CNC machining center to produce the implants. The five - axis capabilities allowed for the creation of complex, curved surfaces with high precision. For example, the contours of the implant that would interface with the patient's vertebrae were machined with a tolerance of ±0.03mm, ensuring a snug fit.

The use of innovative CNC machining techniques also enabled the manufacturer to use a new biocompatible material, a special titanium - alloy with enhanced strength and corrosion resistance. This material was difficult to machine, but the advanced CNC equipment and optimized machining parameters allowed for successful production.

The result was a spinal implant system that had a 30% higher success rate in clinical trials compared to previous models. The improved fit reduced the risk of implant failure and post - operative complications, leading to better patient outcomes and shorter recovery times.

Conclusion

Innovation in CNC precision machined components is not just a trend; it is an imperative for industries across the board. As we have seen, the advancements in technology, such as new materials and advanced machinery, are driving the boundaries of what is possible in CNC machining. The demands for higher precision and cost - efficiency from industries like aerospace, automotive, medical, and electronics are fueling this innovation.

The case studies from the aerospace and medical device fields clearly demonstrate the positive impact of innovation in CNC precision machining. In aerospace, it leads to more fuel - efficient and reliable aircraft, while in the medical field, it results in better - fitting implants and improved patient outcomes. These success stories are not only inspiring but also set a precedent for other industries to follow.

In Yigu Technology conclusion, innovation in CNC precision machined components is key to the progress and competitiveness of modern industries. By staying at the forefront of technological advancements and addressing industry demands, manufacturers can continue to produce high - quality components that meet the ever - changing needs of their customers.

FAQ

- Q: What is the most significant advantage of 5 - axis milling over 3 - axis milling?

A: The most significant advantage of 5 - axis milling is its ability to machine complex 3D shapes in a single setup. This reduces errors associated with multiple setups and can improve machining efficiency by up to 30 - 40% for complex parts compared to 3 - axis milling.

- Q: How do new materials affect CNC precision machining?

A: New materials, such as CFRPs in aerospace and biocompatible materials in medical, offer performance advantages but also pose machining challenges. For example, CFRPs are prone to fiber pull - out and delamination, while titanium alloys used in medical implants have low thermal conductivity, leading to rapid tool wear. Specialized cutting tools and optimized machining parameters are required to overcome these challenges.

- Q: Why is cost - efficiency important in CNC precision machining?

A: Cost - efficiency is important because it directly impacts the competitiveness of manufacturers. By reducing material waste, energy consumption, and tool replacement costs, companies can offer more competitive prices for their products. For example, reducing material waste by 15 - 20% through process optimization can lead to significant cost savings over time.