Introduction

In the world of mechanical engineering, Plastic Planetary Gears have emerged as a revolutionary component, offering a unique blend of versatility and efficiency. These gears play a crucial role in various applications, from small household appliances to complex industrial machinery. Understanding how material choices shape the performance of plastic planetary gears is essential for engineers and designers aiming to optimize their mechanical systems.

Understanding Plastic Planetary Gears

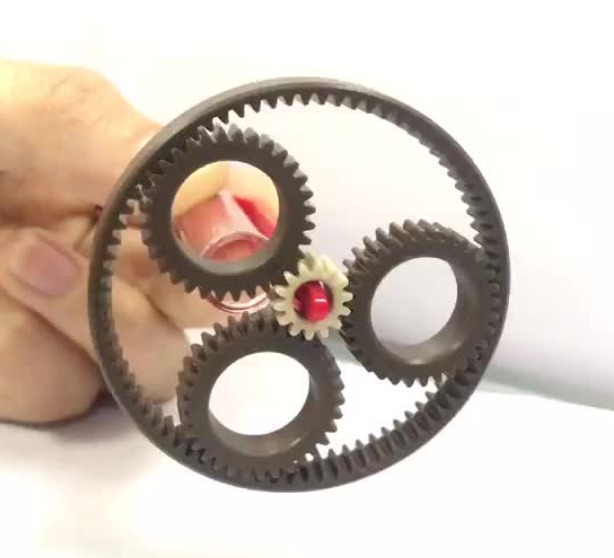

Plastic planetary gears are an integral part of planetary gear systems, which are known for their compact design and high torque - to - weight ratio. In a planetary gear setup, multiple small gears (the planet gears) orbit around a central gear (the sun gear) while being contained within an outer ring gear. This arrangement allows for efficient power transmission and speed reduction.

Plastic planetary gears, made from various types of plastics, have several advantages over their metal counterparts. They are lightweight, which is crucial in applications where reducing weight is a priority, such as in aerospace or portable devices. For example, in a small drone, the use of plastic planetary gears can significantly decrease the overall weight, enabling longer flight times and better maneuverability. They also have excellent noise - damping properties. In household appliances like washing machines or food processors, the use of plastic planetary gears can reduce the noise generated during operation, providing a more pleasant user experience. Additionally, plastic gears are often more cost - effective to produce, making them an attractive option for mass - produced products.

Types of Materials for Plastic Planetary Gears

The performance of plastic planetary gears is highly dependent on the type of plastic material used. There are two main categories of plastics: thermoplastics and thermosets, each with its own sub - materials that offer unique properties for gear applications.

Thermoplastics

Thermoplastics are a popular choice for plastic planetary gears due to their ease of processing and a wide range of available properties.

Nylon

Nylon, also known as polyamide (PA), is a widely used thermoplastic for plastic planetary gears. It has excellent wear resistance, which is crucial for gears that experience continuous meshing and friction. For example, in power tools, the constant rotation and high - torque demands on the gears require a material that can withstand wear over long periods. Nylon's wear - resistant property ensures that the gears can operate smoothly for an extended time without significant degradation.

Nylon also offers good strength, allowing it to handle moderate loads. In applications like small - scale industrial machinery, such as a mini - conveyor system in a food packaging plant, nylon gears can transmit power effectively while enduring the forces exerted during operation. Another remarkable property of nylon is its self - lubricating nature. This means that it can reduce the need for external lubricants, which is beneficial in applications where lubricant contamination is a concern, like in some medical devices or food - processing equipment.

Polyacetal (POM)

Polyacetal, or POM, is another thermoplastic with distinct characteristics that make it suitable for plastic planetary gears. It has high rigidity, which ensures that the gear maintains its shape and dimensional accuracy even under load. In automotive window regulators, POM gears are used because they can precisely control the movement of the window glass, thanks to their high - rigidity property.

POM also has a low friction coefficient. This property not only reduces the energy required to operate the gears but also minimizes wear and tear. In small electric motors used in household appliances like fans or blenders, POM gears can improve the overall efficiency of the motor by reducing frictional losses. The low - friction nature of POM also contributes to its quiet operation, making it an ideal choice for applications where noise reduction is important.

Thermosets

Thermoset plastics are less common than thermoplastics for plastic planetary gears but are used in specific applications where their unique properties are required.

Epoxy Resins

Epoxy resins are known for their high strength. They can withstand heavy loads and are often used in industrial applications where durability is crucial. For example, in large - scale manufacturing equipment, such as injection - molding machines, epoxy - based plastic planetary gears can handle the high - torque and high - stress conditions during operation.

Epoxy resins also have excellent chemical resistance. In chemical processing plants, where gears may be exposed to various corrosive substances, epoxy - resin gears can maintain their integrity and functionality. Their resistance to chemicals ensures a longer service life in harsh chemical environments.

Phenolic Resins

Phenolic resins offer high heat resistance, which makes them suitable for applications where the gears are exposed to elevated temperatures. In some industrial ovens or heat - treatment equipment, phenolic - resin plastic planetary gears can operate effectively without softening or deforming due to the heat.

These resins also have good dimensional stability. This property is important for gears that require precise tooth profiles and accurate meshing. In precision - engineering applications, such as in some high - end optical equipment or measuring instruments, the dimensional stability of phenolic - resin gears ensures smooth and accurate operation.

Comparison of Different Materials

Tabular Comparison

To better understand the differences between materials for plastic planetary gears, the following table presents a comparison of the key properties and typical application scenarios of common materials:

| Material | Strength | Wear Resistance | Temperature Resistance | Cost | Application Scenarios |

| Nylon | Good, can handle moderate loads | Excellent | Moderate heat - deflection temperature, suitable for normal - temperature applications | Relatively low | Power tools, small - scale industrial machinery, food - processing equipment, medical devices |

| Polyacetal (POM) | High rigidity, maintains shape under load | Good, with low friction coefficient | Moderate, suitable for applications with normal - temperature to slightly elevated temperatures | Moderate to high | Automotive window regulators, small electric motors in household appliances, industrial conveyors |

| Epoxy Resins | High, can withstand heavy loads | Good, especially in industrial - grade applications | Varies; some formulations can have high heat resistance | High | Industrial manufacturing equipment like injection - molding machines, chemical processing plants |

| Phenolic Resins | Moderate to high | Good | High, can operate at elevated temperatures | Moderate | Industrial ovens, heat - treatment equipment, precision - engineering applications such as high - end optical equipment |

Performance Analysis

High - Temperature Conditions:

In high - temperature applications, materials like phenolic resins and some high - performance epoxy resins shine. Phenolic resins can maintain their mechanical properties and dimensional stability at temperatures up to 150 - 200°C, making them ideal for gears in industrial ovens or heat - treatment equipment. For example, in a metal - heat - treatment furnace where the operating temperature can reach 180°C, phenolic - resin plastic planetary gears can ensure smooth operation of the mechanical transmission system without significant deformation or degradation. Epoxy resins, especially those formulated with heat - resistant additives, can also handle high - temperature environments. However, their performance may be more limited compared to phenolic resins, with some epoxy - based gears being suitable for temperatures up to around 100 - 150°C depending on the formulation.

High - Load Conditions:

When it comes to high - load applications, epoxy resins and POM show their strengths. Epoxy resins, with their high - strength properties, can handle the significant forces and torques in large - scale industrial equipment. In a large - capacity injection - molding machine, which exerts high - torque forces during the plastic - injection process, epoxy - resin gears can withstand these loads without breaking or deforming. POM, despite not having the same level of strength as epoxy resins, still offers high rigidity. In automotive power - transmission systems, where gears need to transfer power under heavy loads, POM gears can be used in certain components due to their ability to maintain dimensional accuracy under stress.

High - Speed Conditions:

For high - speed applications, materials with low friction and good wear resistance are crucial. Nylon is a great choice here. Its self - lubricating property reduces friction, and its excellent wear - resistance ensures a long service life even at high rotational speeds. In a high - speed power - tool motor, nylon gears can operate smoothly, reducing the need for frequent maintenance due to wear. POM also performs well in high - speed applications because of its low - friction coefficient. It can reduce the energy losses associated with friction, which is beneficial for applications where high - speed operation requires high efficiency, such as in some high - speed small electric motors.

Factors Influencing Material Selection

Operating Conditions

Temperature

Temperature has a significant impact on the performance of plastic planetary gears. Different plastic materials have varying temperature - resistance capabilities. For example, materials like nylon have a moderate heat - deflection temperature. Nylon gears can typically operate well in normal - temperature applications, such as in household appliances where the operating temperature is usually around room temperature to slightly elevated temperatures (up to about 80 - 100°C). However, in high - temperature environments, nylon may start to lose its mechanical properties and dimensional stability.

On the other hand, materials such as phenolic resins and PEEK are more suitable for high - temperature applications. Phenolic resins can withstand temperatures up to 150 - 200°C, making them ideal for gears in industrial ovens or heat - treatment equipment. PEEK, with its high - temperature resistance, can operate at even higher temperatures, often up to 260°C continuously and can briefly withstand temperatures as high as 300°C. In applications like aerospace or high - performance automotive transmissions, where gears are exposed to extreme heat due to high - speed operation and high - load conditions, PEEK is a preferred choice.

Load

The load that plastic planetary gears need to bear is a crucial factor in material selection. Nylon, with its good strength, can handle moderate loads. In applications such as small - scale industrial machinery or power tools, nylon gears can effectively transmit power under normal operating loads. The self - lubricating property of nylon also helps in reducing wear and tear under these moderate - load conditions.

Polyacetal (POM) has high rigidity, which allows it to maintain its shape under load better than some other plastics. It can handle relatively high loads compared to nylon and is often used in applications like automotive window regulators or industrial conveyors. The high - rigidity property of POM ensures that the gear teeth do not deform significantly under the applied forces, enabling smooth and accurate power transmission.

Epoxy resins, with their high - strength properties, are designed to withstand heavy loads. In large - scale industrial manufacturing equipment, such as injection - molding machines, where the gears are subjected to high - torque and high - stress conditions, epoxy - resin plastic planetary gears are a reliable choice. The molecular structure of epoxy resins provides the necessary strength to resist the large forces exerted during operation.

Speed

For high - speed applications, materials with low friction and good wear resistance are essential. Nylon is a great option because of its self - lubricating nature. In high - speed power - tool motors or small electric motors in some high - speed rotating equipment, nylon gears can operate smoothly. The self - lubricating property reduces friction, which in turn reduces energy losses and heat generation. This not only improves the efficiency of the gear system but also extends the service life of the gears by minimizing wear.

POM also performs well at high speeds due to its low - friction coefficient. It can reduce the amount of energy wasted in overcoming friction, which is crucial for applications where high - speed operation requires high efficiency. In high - speed small electric motors, POM gears can contribute to better overall performance by reducing frictional losses and ensuring smooth rotation.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the criticality of material selection for plastic planetary gears. We believe that a one - size - fits - all approach doesn't work. Each customer's application has unique requirements, whether it's in terms of load - bearing capacity, temperature resistance, or cost constraints.

We leverage our in - depth technical expertise to provide customized material solutions. For instance, if a customer is developing a small - scale, battery - powered device where weight and cost are crucial factors, we might recommend nylon - based plastic planetary gears due to their lightweight and cost - effective nature. On the other hand, for industrial applications with high - temperature and high - load demands, we would suggest materials like PEEK or high - performance epoxy resins. By collaborating closely with customers, analyzing their specific needs, and using our knowledge of material properties, we aim to offer the best - suited material choices for plastic planetary gears, ensuring optimal performance and long - term reliability.

FAQ

What are the main advantages of nylon in plastic planetary gears?

Nylon, or polyamide (PA), offers several key advantages in plastic planetary gears. It has excellent wear resistance, which is crucial as gears experience continuous meshing and friction. This property ensures that the gears can operate smoothly for an extended time without significant degradation. Nylon also has good strength, allowing it to handle moderate loads effectively. Another remarkable property is its self - lubricating nature. This reduces the need for external lubricants, which is beneficial in applications where lubricant contamination is a concern, such as in medical devices or food - processing equipment.

How does temperature affect the choice of materials for plastic planetary gears?

Temperature has a significant impact on the material selection for plastic planetary gears. Different plastic materials have varying temperature - resistance capabilities. In high - temperature environments, materials with low heat - deflection temperatures, like nylon (which is suitable for normal - temperature applications up to about 80 - 100°C), may start to lose their mechanical properties and dimensional stability. Materials such as phenolic resins and PEEK are more suitable for high - temperature applications. Phenolic resins can withstand temperatures up to 150 - 200°C, and PEEK can operate at even higher temperatures, often up to 260°C continuously and briefly withstand 300°C. In low - temperature conditions, some materials may become brittle. So, it's essential to choose a material that can maintain its toughness and other mechanical properties at the operating temperature of the gear system.

Is it possible to reduce costs without sacrificing the performance of plastic planetary gears?

Yes, it is possible. One way is to optimize the design of the gears. Through advanced simulation and analysis, the gear geometry can be refined to use less material without sacrificing performance. For example, removing unnecessary material from non - critical areas of the gear while maintaining the structural integrity. Another method is to source materials from reliable suppliers who can offer competitive prices. Additionally, in some cases, a combination of different materials can be used in the gear system. Using a more cost - effective material for non - critical components and a higher - performance, more expensive material for the parts that bear the highest loads or operate under the most demanding conditions. In mass - production applications, economies of scale can also be achieved, reducing the per - unit cost of the plastic planetary gears.

Conclusion

In conclusion, the world of Plastic Planetary Gears is a fascinating one, with material choices being at the heart of their performance. Thermoplastics like nylon and POM, along with thermosets such as epoxy resins and phenolic resins, each offer unique properties that make them suitable for different applications.

The operating conditions, including temperature, load, and speed, play a crucial role in determining the right material. High - temperature applications demand materials with high heat - resistance, while high - load scenarios require materials with sufficient strength. Cost is also a significant factor, especially in mass - production, and strategies like design optimization and sourcing from reliable suppliers can help balance cost and quality.

When it comes to making decisions about plastic planetary gears for your mechanical systems, it's essential to carefully consider all these aspects. By understanding the properties of different materials and how they interact with the operating conditions, you can make an informed choice that ensures the long - term efficiency and reliability of your equipment. Don't hesitate to explore further, consult with experts, and analyze your specific requirements to find the perfect material solution for your plastic planetary gear needs.