Introduction

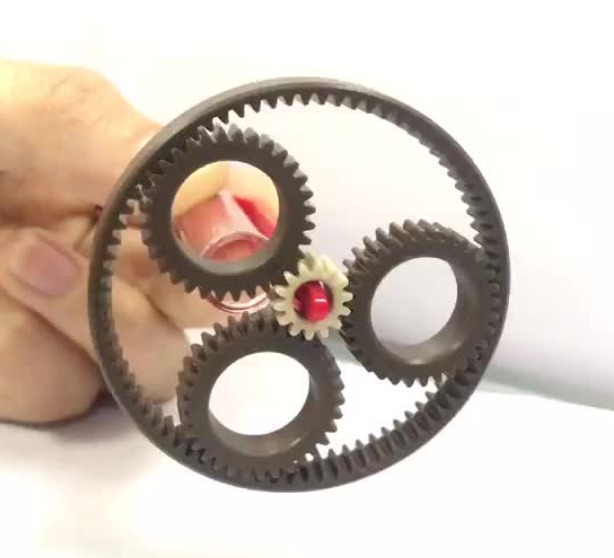

In the vast landscape of modern industrial machinery, the plastic gear wheel has emerged as a crucial component, quietly revolutionizing the way power is transmitted and motion is controlled. From the tiniest precision instruments to large - scale manufacturing equipment, plastic gear wheels are omnipresent, playing a pivotal role in countless mechanical systems.

These unassuming components have come a long way from their humble beginnings. Initially seen as a simple substitute for their metal counterparts in low - load applications, plastic gear wheels have evolved into highly engineered solutions that can meet the demands of some of the most challenging industrial environments. Their development is a story of continuous innovation, driven by the need for lighter, more efficient, quieter, and cost - effective mechanical components.

As industries strive for greater sustainability, energy efficiency, and miniaturization, the plastic gear wheel stands at the forefront of this technological evolution. This article will delve deep into the history, materials, manufacturing processes, applications, and future prospects of plastic gear wheels, exploring how they have transformed and continue to shape the world of mechanical engineering.

Applications of Plastic Gear Wheels

Plastic gear wheels have found their way into a vast array of industries, each leveraging their unique properties to enhance product performance and functionality.

In the Automotive Industry

In the automotive sector, the pursuit of fuel efficiency and reduced emissions has led to the increased use of plastic gear wheels. For example, they are used in power windows, where the smooth and quiet operation of plastic gears ensures a pleasant user experience. A study by [Automotive Research Institute] found that replacing metal gears with plastic ones in power window mechanisms reduced the overall noise level by up to 20 decibels. They are also employed in the throttle control systems. The lightweight nature of plastic gears helps in reducing the overall weight of the vehicle, which in turn improves fuel efficiency. According to industry data, a 10% reduction in vehicle weight can lead to a 6 - 8% improvement in fuel economy. Additionally, plastic gears are used in the cooling fan assemblies, where their corrosion - resistance properties ensure a longer lifespan, especially in harsh under - hood environments.

In Consumer Electronics

Consumer electronics, such as cameras, printers, and small portable fans, rely heavily on plastic gear wheels. In a digital camera's autofocus mechanism, plastic gears enable precise and quiet movement of the lens. They are also used in the tape - drive mechanisms of VCRs (although VCRs are less common now) and in the paper - feed systems of printers. For instance, in an inkjet printer, plastic gears ensure that the paper moves smoothly through the printing process. The self - lubricating properties of many plastic materials used in these gears reduce the need for additional lubricants, which is crucial in small, compact electronic devices where space is limited. Moreover, the low cost of plastic gears makes them an ideal choice for mass - produced consumer electronics, helping to keep the overall product cost down.

In Medical Devices

The medical device industry has specific requirements, and plastic gear wheels meet many of them. In insulin pumps, plastic gears are used to precisely control the delivery of insulin. Their high precision manufacturing capabilities ensure that the correct dosage is administered to the patient. A research paper published in [Medical Engineering Journal] stated that plastic gears in insulin pumps can achieve a dosing accuracy of within 1% of the prescribed amount. They are also used in surgical robots, where the smooth and quiet operation of the gears is essential during delicate procedures. The biocompatibility of certain plastics used in these gears is a significant advantage, as it ensures that the gears do not cause any adverse reactions when in contact with the human body. Additionally, the sterilizability of plastic gears makes them suitable for use in various medical equipment that needs to be thoroughly cleaned and disinfected between uses.

Yigu Technology's View

Yigu Technology, as a non - standard plastic metal products custom supplier, firmly believes in the bright future of plastic gear wheels. With our expertise in custom manufacturing, we recognize that the demand for customized plastic gear wheels is on the rise. Different industries have unique requirements, and we are well - equipped to meet these demands by providing tailor - made solutions.

Our advanced manufacturing processes enable us to produce plastic gear wheels with high precision, even for the most complex designs. We understand that in industries such as aerospace and high - end medical devices, precision is non - negotiable. By using state - of - the - art technology, we can ensure that our plastic gear wheels meet the strictest quality standards.

Moreover, we are committed to keeping up with the latest trends in material science. As new, more advanced plastic materials are developed, we are quick to incorporate them into our manufacturing processes. This allows us to offer our clients plastic gear wheels with enhanced properties, such as improved heat resistance, greater strength, and better chemical resistance. We believe that by staying at the forefront of technology and material innovation, we can contribute to the continued growth and success of the plastic gear wheel industry.

FAQ

What are the main materials used for plastic gear wheels?

Common materials for plastic gear wheels include nylon (polyamide, PA) and polyoxymethylene (POM). Nylon has excellent comprehensive mechanical properties. It has high mechanical strength and good toughness. Its self - lubricating property reduces friction, making it suitable for long - term use as a transmission component. For example, nylon 46 has a high heat - deflection temperature and can be used continuously at 150°C. When reinforced with glass fiber, its heat - deflection temperature can reach over 250°C. However, nylon has a relatively high water absorption rate, which may affect the dimensional stability of parts. POM, known as "acetal resin", has high mechanical strength and rigidity, the highest fatigue strength among common plastics, and excellent environmental resistance and solvent resistance. It is highly resistant to repeated impacts and has good electrical properties and self - lubricating and wear - resistant characteristics. But its working temperature is relatively low, generally around 70 - 80°C, and it is not resistant to hydrolysis.

How do plastic gear wheels compare to metal gear wheels in terms of durability?

In general, metal gear wheels are more durable in high - load and high - stress applications. Metals such as steel have high strength and can withstand large forces without significant deformation or breakage. However, plastic gear wheels have their own advantages in certain environments. In low - load applications, plastic gear wheels can have a long service life. Their self - lubricating properties reduce wear, and in some cases where corrosion resistance is required, such as in contact with certain chemicals or in humid environments, plastic gear wheels outperform metal ones. For example, in a household humidifier, plastic gear wheels can operate smoothly for a long time without being corroded by water vapor. In high - speed applications with low - load conditions, plastic gear wheels can also function well due to their low inertia. But in high - load and high - speed combined conditions, metal gear wheels are usually more durable as plastic gear wheels may experience excessive wear, deformation, or even melting due to heat generated by friction.

Can plastic gear wheels be used in high - speed applications?

Plastic gear wheels can be used in high - speed applications to a certain extent, but there are limitations. The main limiting factors are heat generation and mechanical strength. At high speeds, the friction between plastic gear teeth can generate a large amount of heat. Since plastics generally have lower heat - dissipation capabilities compared to metals, this can lead to softening or even melting of the plastic if the heat is not effectively dissipated. Additionally, the mechanical strength of plastics may not be sufficient to withstand the high - speed centrifugal forces and impact forces in some cases. However, with the development of materials and manufacturing technologies, some high - performance plastics and reinforced plastics have been developed. For example, plastics reinforced with carbon fiber can have significantly improved strength and heat resistance, making them more suitable for high - speed applications. Also, proper lubrication and heat - dissipation measures, such as using heat - conducting lubricants or adding heat - sinks, can help plastic gear wheels operate more stably in high - speed scenarios.