What is Bulk 3D Printing Service?

Bulk 3D printing service, also known as mass 3D printing, is a revolutionary manufacturing solution that enables the production of a large quantity of three - dimensional objects in a single run or over a short period.

At its core, bulk 3D printing is based on digital model files, typically in formats like STL (Stereolithography) or OBJ (Object File Format). These files contain all the geometric information of the object to be printed. A 3D printer then reads this digital data and uses various materials, such as plastics (e.g., PLA - Polylactic Acid, ABS - Acrylonitrile Butadiene Styrene), metals (e.g., aluminum, titanium), ceramics, or even composite materials, to build the object layer by layer.

For example, in the automotive industry, when manufacturing a large number of custom - designed car parts, bulk 3D printing can be used. Instead of traditional manufacturing methods that require complex molds and long production lines, a 3D printer can directly print these parts according to the digital models. This not only reduces the time and cost of mold - making but also allows for more flexibility in design changes.

In contrast to traditional manufacturing techniques like injection molding or CNC machining, bulk 3D printing has distinct advantages. Injection molding, for instance, is highly efficient for high - volume production but requires high initial investment in mold - making. The mold - making process is time - consuming and expensive, and any design modification would mean creating a new mold. CNC machining, on the other hand, is better suited for precision manufacturing of individual or small - batch parts, but it can be wasteful of materials and relatively slow for large - scale production.

Bulk 3D printing bridges the gap between small - scale prototyping and large - scale production. It allows for the production of complex geometries that are difficult or impossible to achieve with traditional methods. This technology has opened up new possibilities for industries such as aerospace, healthcare, architecture, and consumer goods, enabling them to produce high - quality products in large quantities while maintaining design freedom and cost - effectiveness.

The Mainstream Technologies of Bulk 3D Printing

FDM (Fused Deposition Modeling)

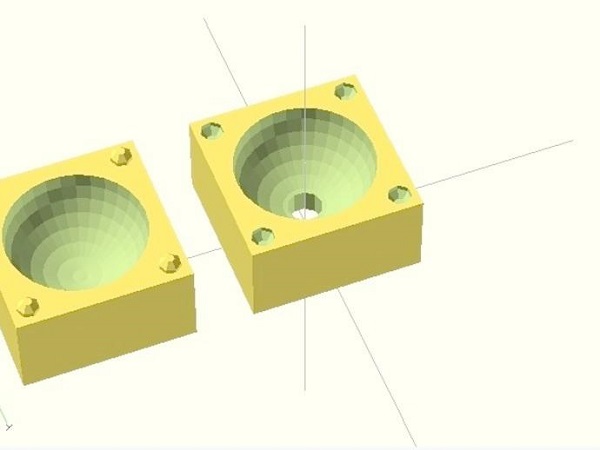

FDM is a widely - used 3D printing technology in bulk production. Its working principle is relatively straightforward. The printing material, usually in filament form, is fed into a heated nozzle. As the nozzle moves along the X, Y, and Z axes according to the digital model instructions, the melted material is extruded from the nozzle. Once extruded, the material cools down and solidifies immediately, gradually building up the object layer by layer.

In bulk 3D printing, FDM has several distinct advantages. Firstly, it has a relatively low cost. The materials used, such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), are inexpensive, and the equipment itself is also more affordable compared to some other 3D printing technologies. Secondly, it is easy to operate, which means that less - skilled operators can also handle the printing process. For example, in the production of small - scale consumer goods like toys or simple household items, FDM can be a cost - effective choice for bulk production.

SLA (Stereolithigraphy Apparatus)

SLA technology works by using ultraviolet (UV) light to cure liquid photopolymer resin. A digital model is sliced into thin layers, and a UV laser beam or a digital light projector traces the shape of each layer onto the surface of the liquid resin. As the light hits the resin, it causes a chemical reaction that turns the liquid resin into a solid plastic. After each layer is cured, the build platform is lowered slightly, and a new layer of resin is spread over the previously cured layer, repeating the process until the entire object is formed.

SLA is highly regarded for its ability to produce parts with high precision and smooth surfaces. The layer thickness can be as thin as a few micrometers, allowing for the creation of intricate details. In bulk 3D printing, SLA is well - suited for manufacturing products that require high - level aesthetics and precision, such as jewelry, dental models, and small - scale high - end consumer electronics components. For instance, in the jewelry industry, SLA can be used to print detailed and delicate jewelry prototypes in large quantities, which can then be used for casting precious metals.

3DP (Three Dimensional Printing and Gluing)

3DP technology starts with a powder bed. A thin layer of powder, which can be materials like gypsum, metal, or plastic powder, is spread evenly across the build platform. Then, a printhead moves across the powder bed and sprays a liquid binder onto the areas where the object is to be formed. The binder causes the powder particles to stick together, creating a solid layer. This process is repeated layer by layer until the 3D object is complete.

One of the main advantages of 3DP in bulk 3D printing is its high - speed printing capability. Since it doesn't require melting or curing processes like some other technologies, it can build layers quickly. Additionally, 3DP can produce objects in a wide range of colors, making it an ideal choice for applications such as architectural models, art design, and educational products. For example, in the production of large - scale architectural models for real - estate exhibitions, 3DP can print multiple models with different color - coded components in a relatively short time.

SLS (Selecting Laser Sintering)

SLS uses a high - power laser to sinter powdered materials, such as plastics, metals, or ceramics. The powder is spread in a thin layer across the build platform, and the laser scans the surface, heating the powder particles to their melting point. As the powder particles melt, they bond together, forming a solid layer. After each layer is completed, the build platform is lowered, a new layer of powder is spread, and the process repeats.

SLS is particularly suitable for bulk manufacturing of high - strength and heat - resistant components. In industries like automotive and aerospace, SLS can be used to produce metal parts such as engine components, brackets, and structural parts. For example, in the automotive industry, SLS can print lightweight yet strong metal parts for vehicle engines, reducing the overall weight of the vehicle and improving fuel efficiency. The ability to create complex geometries without the need for additional support structures also makes SLS a popular choice for producing parts with internal cavities or lattice structures.

Yigu Technology's View on Bulk 3D Printing Service

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the role of bulk 3D printing service. With years of experience in the field of custom manufacturing, we understand the diverse and complex needs of customers.

Bulk 3D printing service enables us to better meet customers' customization requirements. In the past, when dealing with non - standard products, traditional manufacturing methods often faced difficulties in handling complex geometries and small - batch production. However, 3D printing breaks these limitations. It allows us to produce unique plastic and metal products according to customers' digital designs quickly, whether it's a complex - shaped plastic component or a high - precision metal part.

Moreover, it significantly improves production efficiency. By eliminating the need for time - consuming mold - making processes in traditional manufacturing, we can start production immediately once we receive the digital model. This not only shortens the production cycle but also reduces costs, especially for small - to medium - sized production runs.

Yigu Technology has been closely following the development of 3D printing technology. Our professional team has in - depth knowledge of different 3D printing materials and techniques. We are committed to integrating bulk 3D printing service into our production system to provide more high - quality, cost - effective, and customized products to our customers.

FAQ about Bulk 3D Printing Service

What types of materials can be used in bulk 3D printing?

Common materials for bulk 3D printing include metals like aluminum, titanium, and stainless steel. Aluminum is often used in the aerospace and automotive industries for its lightweight and high - strength properties, such as in the production of aircraft components and car engine parts. Titanium, known for its excellent corrosion resistance and high strength - to - weight ratio, is widely applied in medical implants and high - end aerospace components. Stainless steel is used in various industrial applications that require good corrosion resistance and mechanical strength, like in the manufacturing of pipes and machinery parts.

Plastics such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are also popular. PLA, being biodegradable, is suitable for consumer products, educational models, and disposable items. ABS, with its high strength and heat resistance, is commonly used in the production of electronic device housings and automotive interior parts.

Ceramics can be used in 3D printing for applications that demand high - temperature resistance and wear - resistance, such as in the production of ceramic engine components, dental restorations, and industrial kiln linings.

How accurate is bulk 3D printing?

The accuracy of bulk 3D printing is affected by multiple factors, including the 3D printing technology used, the quality of the equipment, and the printing parameters. Generally, for FDM (Fused Deposition Modeling) technology, the typical accuracy ranges from ±0.1 to ±0.5 mm. SLA (Stereolithography Apparatus) can achieve an accuracy of about ±0.05 to ±0.15 mm, while SLS (Selective Laser Sintering) usually has an accuracy of around ±0.1 to ±0.3 mm.

To improve accuracy, optimizing parameters is crucial. For example, adjusting the nozzle temperature according to the material's properties ensures proper material flow and adhesion, reducing dimensional errors. Using high - quality filaments or powders also helps. Additionally, post - processing techniques like sanding, polishing, and chemical treatment can further enhance the accuracy and surface finish of the printed parts, reducing surface roughness and improving dimensional accuracy.

Can bulk 3D printing be used for mass production?

Bulk 3D printing can be used for mass production to a certain extent. Compared with traditional mass - production methods like injection molding, 3D printing has some advantages. It allows for greater design freedom, enabling the production of complex geometries without the need for expensive molds. This is beneficial for products with intricate internal structures or customized features. It also has a shorter lead time, as there is no need to wait for mold - making processes.

However, it also has limitations. The printing speed of 3D printers is generally slower than traditional production methods, which may limit the production volume in a given time. The cost per unit can be higher, especially when using expensive materials or high - end 3D printers. For products that require extremely high precision, traditional manufacturing methods may still be more suitable. So, while bulk 3D printing has its place in mass production, it is often best combined with traditional methods to meet different production requirements.