Overview of Custom 3D Printing Services

Definition and Purpose

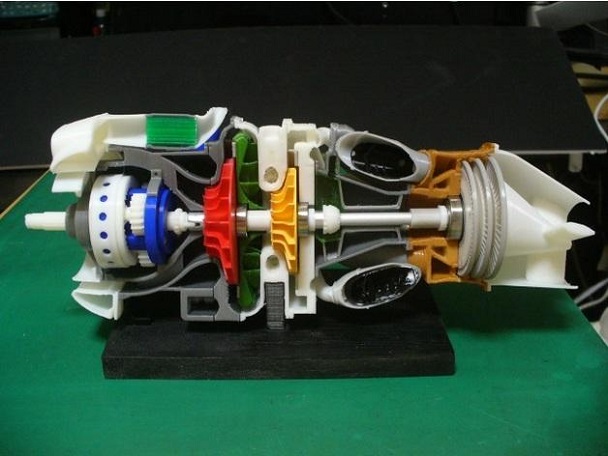

Custom 3D printing services leverage additive manufacturing technologies to produce tailored objects based on specific design specifications. Unlike traditional manufacturing, which often involves subtracting or shaping material from a larger block, 3D printing builds objects layer by layer from a digital model. This method allows for the creation of complex and intricate geometries that would be either impossible or prohibitively expensive to manufacture using conventional techniques. The primary aim of custom 3D printing is to offer bespoke solutions, whether for a unique product designed for individual needs or for specialized components in industrial applications.

Industries Served

The versatility of custom 3D printing services allows them to cater to a broad array of industries, including:

- Manufacturing: Rapid prototyping and small-batch production runs.

- Healthcare: Patient-specific medical devices, prosthetics, and implants.

- Aerospace: Lightweight, high-strength components for aircraft and spacecraft.

- Automotive: Custom parts and tools for vehicle modifications.

- Consumer Goods: Personalized products, such as jewelry, phone cases, and home décor.

- Education: Providing tactile learning aids and physical models for enhanced teaching.

Benefits of Custom 3D Printing

Uniqueness and Personalization

One of the standout benefits of custom 3D printing is its ability to produce highly personalized products. Whether it's a custom prosthetic or a unique piece of art, 3D printing allows for precise tailoring to individual needs and preferences. This personalization not only leads to greater customer satisfaction but also fosters brand loyalty. Customers increasingly expect products that reflect their unique style or functional requirements, making custom 3D printing an ideal solution.

Speed and Cost-Effectiveness

Custom 3D printing dramatically shortens the time from concept to finished product. Traditional manufacturing often requires weeks or even months for tooling, setup, and production. In contrast, 3D printing can create functional prototypes within days or even hours, enabling businesses to speed up product development cycles. Moreover, 3D printing eliminates the need for expensive tooling and reduces material waste, making it a cost-effective solution for both small-scale and large-scale production.

Prototyping and Product Development

For businesses involved in product innovation, custom 3D printing offers unmatched flexibility. Designers can quickly iterate on their ideas, tweaking and refining designs without incurring the high costs of traditional retooling. This iterative process accelerates innovation, allowing for faster creation and testing of functional prototypes. As a result, businesses can better assess designs and optimize them before committing to mass production, reducing risks and increasing the chances of market success.

Considerations for Custom 3D Printing

Material Selection

Choosing the right material is crucial for achieving the desired properties of the final product. Various materials are available, each offering different characteristics like strength, flexibility, heat resistance, and biocompatibility. Some commonly used materials in 3D printing include:

- PLA (Polylactic Acid): A biodegradable, eco-friendly plastic commonly used for prototypes and general-purpose items.

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and durability, suitable for more functional, everyday parts.

- Resin: Ideal for highly detailed and smooth finishes, making it perfect for intricate designs.

- Metal Alloys: Used for manufacturing high-strength parts in industries such as aerospace and automotive.

- Biomaterials: Tailored for medical applications, ensuring compatibility with human tissues and other medical standards.

Print Quality and Resolution

The resolution of the 3D print directly affects the quality of the final product. Higher resolution prints yield finer details and smoother surfaces, but they typically take longer to produce and may incur higher costs. Striking the right balance between print quality, speed, and budget is essential, depending on the specific requirements of the project. High-resolution prints are generally favored for products that require precision and aesthetics, while lower resolutions may be sufficient for more functional or prototyping applications.

Post-Processing Techniques

While 3D printing can produce functional parts, additional post-processing is often needed to enhance their appearance, durability, and functionality. Common post-processing techniques include:

- Support Removal: After printing, the support structures used to hold parts in place during printing must be removed.

- Sanding and Polishing: These methods smooth out rough surfaces for a refined, professional finish.

- Painting: Adds color and texture to improve the aesthetics of the final product.

- Heat Treatment: Techniques like annealing or tempering are used to improve material properties such as strength and durability.

- Assembly: Multiple printed components may need to be assembled into a single functional unit.

Case Studies and Success Stories

Real-World Applications

Several industries have already harnessed the potential of custom 3D printing to drive innovation and solve complex challenges:

- Medical Field: A hospital utilized custom 3D printing to create a bespoke prosthetic arm for a young amputee. The personalized fit significantly improved the patient's mobility and overall quality of life.

- Aerospace: An aerospace company used custom 3D printing to reduce the weight of a critical aircraft component by 30%, enhancing fuel efficiency and overall performance.

- Automotive: A car manufacturer produced a limited edition model featuring custom 3D-printed interior panels, providing customers with a unique and personalized driving experience.

Industry-Specific Benefits

Each industry benefits from custom 3D printing in unique ways:

- Healthcare: Custom medical devices, such as implants and surgical guides, can be designed specifically for individual patients, improving both treatment outcomes and comfort.

- Aerospace: 3D printing aids in rapid prototyping, enabling manufacturers to develop lightweight yet high-strength parts that improve aircraft performance.

- Automotive: Custom 3D printing offers bespoke parts and tooling solutions that streamline production, reduce costs, and enhance the customization of vehicles.

- Consumer Goods: Personalized products can increase customer engagement and offer unique selling points that set brands apart in a competitive market.

Choosing a Custom 3D Printing Service Provider

Criteria for Selection

When evaluating a custom 3D printing service provider, it's important to consider several key factors:

- Experience and Expertise: Opt for a provider with a proven track record in your specific industry to ensure they understand your needs.

- Material Options: Ensure the provider offers a diverse range of materials suited for your project’s requirements.

- Print Quality: Examine samples of their work to assess print resolution and finish quality.

- Turnaround Time: Quick delivery is crucial, especially for time-sensitive projects.

- Cost: Compare pricing to ensure you are getting competitive rates without compromising on quality.

- Customer Support: Choose a provider that offers robust customer service to assist with any issues or inquiries.

Service Comparison

To find the best provider, compare different companies based on their capabilities, reputation, and client feedback. Some companies may specialize in specific industries or materials, so make sure their expertise aligns with your project requirements.

Customer Reviews and Testimonials

Reading customer reviews and testimonials can offer valuable insights into the provider's reliability, quality, and customer service. Look for detailed feedback, particularly from clients in your industry, to gauge how well the provider can meet your needs.

FAQs

What are the primary benefits of custom 3D printing services?

Custom 3D printing offers key benefits such as the ability to create unique, personalized items, faster turnaround times compared to traditional methods, cost savings from reduced waste and tooling, and greater flexibility for design iterations in product development. These advantages make it an attractive option across various industries.

How do I choose the right material for my custom 3D printing project?

Selecting the right material depends on the intended application and specific requirements like strength, flexibility, heat resistance, and biocompatibility. It's important to assess the functional needs of the part, as well as the aesthetic and durability factors. Consult with your 3D printing service provider to ensure the material aligns with your project goals.

What post-processing techniques are commonly used in custom 3D printing?

Common post-processing techniques include support removal, sanding, polishing, painting, heat treatment, and assembly. These techniques enhance the appearance, functionality, and durability of the printed parts, ensuring they meet your quality standards.

Custom 3D printing services offer incredible flexibility and innovation across a variety of industries. By understanding the benefits, considerations, and best practices, businesses and individuals can leverage this technology to create personalized, cost-effective, and high-quality products tailored to their unique needs.