What is Rapid Tooling?

Rapid tooling, in essence, is the application of additive manufacturing technologies, commonly known as 3D printing, to create molds or mold components. This innovative approach revolutionizes the traditional tool - making process.

Traditionally, manufacturing a mold involved a series of complex steps. First, a design was created on computer - aided design (CAD) software. Then, through processes like machining, where metal was cut and shaped, the mold was gradually formed. This often required highly skilled workers, expensive machinery, and a significant amount of time. For example, creating a medium - sized injection mold using traditional methods could take anywhere from 4 to 8 weeks.

In contrast, rapid tooling streamlines this process. With 3D printing, the digital design from CAD software is directly translated into a physical mold. The printer deposits layers of material, one on top of the other, until the mold is complete. This not only reduces the number of steps but also slashes the production time. A similar medium - sized injection mold made through rapid tooling can be completed in as little as 1 to 2 weeks.

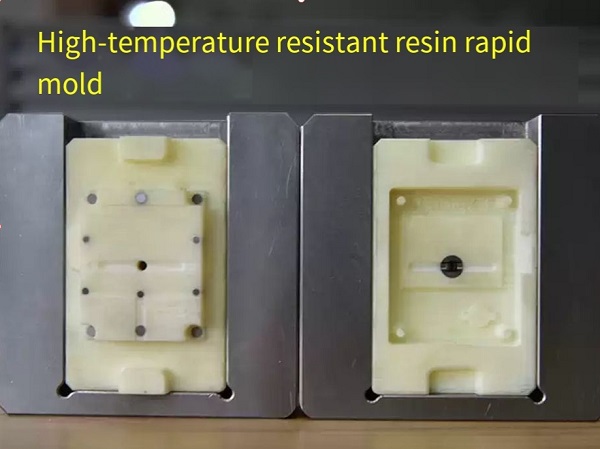

The materials used in rapid tooling are also diverse. While traditional tool - making mainly relied on metals like steel, rapid tooling can use a variety of materials such as plastics, composite materials, and even some metals. For instance, some 3D printers can use a type of plastic - based resin that, when cured by light, forms a strong and heat - resistant material suitable for low - volume injection molding. There are also metal 3D printers that can sinter metal powders together to create molds with high strength and durability, rivaling those made from traditional methods.

Different Angles of Rapid Tooling Definition

From the Technological Aspect

In the realm of rapid tooling, technology plays a pivotal role. One of the core technological applications is 3D printing within additive manufacturing. For example, in material extrusion, which is commonly used in Fused Deposition Modeling (FDM) 3D printers. In rapid tooling, a thermoplastic filament is fed into an extruder head. The head heats the filament until it becomes molten and then extrudes it layer by layer according to the digital model. This process is ideal for creating molds with relatively simple geometries and is cost - effective, especially when using materials like acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA).

Material jetting is another technology. It works by ejecting tiny droplets of liquid material, such as a photosensitive resin, onto a build platform. Each droplet is precisely placed, and then a UV light cures the resin immediately, solidifying the layer. This method allows for high - resolution and detailed mold production, suitable for creating intricate mold cavities or fine surface details that are required for products with complex designs.

In Terms of Time and Cost

When comparing rapid tooling with traditional tooling in terms of time and cost, the differences are significant.

| Aspect | Traditional Tooling | Rapid Tooling |

| Time to Produce | 4 - 8 weeks for a medium - sized injection mold | 1 - 2 weeks for a similar medium - sized injection mold |

| Cost | High. Expensive machinery, skilled labor, and long production times contribute to high costs. A traditional steel injection mold for a small - scale production run might cost \(10,000 - \)50,000. | Lower. Reduced labor requirements, shorter production times, and the ability to use more cost - effective materials. A rapid - tooled injection mold using 3D - printed materials could cost \(2,000 - \)10,000 for the same small - scale production run. |

The reduced time in rapid tooling means that companies can quickly respond to market demands. For example, if a company wants to test - market a new product, with rapid tooling, they can have the molds ready in a fraction of the time it would take with traditional methods, thus accelerating the time - to - market of the new product.

Regarding Product Development

Rapid tooling is a game - changer in product development. It enables the quick production of prototype molds. With these prototype molds, companies can rapidly produce sample products. This allows for early verification of product design. Designers can identify flaws in the product's form, fit, or function much earlier in the development cycle.

For instance, in the development of a new consumer electronics device, rapid tooling can be used to create prototype injection molds for the device's casing. These molds can then be used to produce sample casings. By testing these samples, engineers can check for proper assembly, ergonomics, and aesthetics. Any design issues can be addressed immediately, and the mold can be re - designed and re - printed quickly. This iterative process of design - test - improve is greatly accelerated, leading to better - designed products in a shorter period.

Real - World Examples Proving its Authority

Several real - world examples can further illustrate the significance and reliability of rapid tooling. Take a well - known consumer electronics company as an example. When they were developing a new line of smartphones, they faced intense competition in the market. Time - to - market was crucial for them to gain a competitive edge.

Using traditional tooling methods, the development of injection molds for the phone's casing and internal components would have taken months. However, they opted for rapid tooling. By leveraging 3D printing technology, they were able to create prototype molds within a week. These molds were used to produce sample casings and components, allowing their engineering team to quickly test the design for any flaws.

Through this iterative process of design - test - improve enabled by rapid tooling, they identified and fixed several design issues related to the fit of internal components and the ergonomics of the phone's exterior. As a result, they managed to launch the new smartphone 2 months earlier than initially planned using traditional methods. This early launch led to a 30% increase in initial market share as they were able to capture the attention of early - adopters before their competitors.

Another example is from the automotive industry. A car manufacturer was developing a new concept car for an upcoming auto show. They needed to create unique and complex molds for the car's body panels and interior trim parts. With rapid tooling, they were able to design and produce these molds in a fraction of the time compared to traditional tool - making. The molds were made using a combination of 3D - printed composite materials and metal inserts for high - stress areas. This not only reduced the production time but also lowered the cost of tooling by 40%. The concept car was a huge success at the auto show, generating significant interest from consumers and investors alike, all thanks to the agility provided by rapid tooling in the development process.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom supplier, Yigu Technology highly values rapid tooling. In custom production, rapid tooling allows us to respond swiftly to customer demands. For example, when a client has an urgent need for a new product prototype, rapid tooling enables us to quickly create the necessary molds. This reduces the lead time from weeks to just a few days in some cases.

We can also flexibly adjust the molds according to the customer's design changes. Since rapid tooling uses digital design and 3D printing, making modifications to the mold design is relatively easy. We can simply adjust the digital model and then re - print the mold, eliminating the need for complex and time - consuming re - machining processes as in traditional tooling. This flexibility not only improves customer satisfaction but also enhances our competitiveness in the market.

FAQ

What are the main technologies used in rapid tooling?

The main technologies in rapid tooling include binder jetting in 3D printing. In this technology, a binder is selectively deposited onto a bed of powder material, such as metal or ceramic powder. The binder bonds the powder particles together layer by layer to form the mold. Another technology is directed energy deposition. Here, a focused energy source like a laser or electron beam melts and fuses the feedstock material, which can be metal wire or powder, as it is being deposited. This is suitable for creating large - scale molds or adding features to existing molds. Material extrusion, like in Fused Deposition Modeling (FDM), is also commonly used, where a thermoplastic filament is melted and extruded to build the mold structure layer by layer.

How much time can rapid tooling save compared to traditional tooling?

Typically, for a medium - sized injection mold, traditional tooling can take 4 - 8 weeks to produce. In contrast, rapid tooling can complete the same mold in 1 - 2 weeks. For example, in a case where a company was developing a new product, the traditional tooling process for the injection mold was estimated to take 6 weeks. But by using rapid tooling, they managed to have the mold ready in just 10 days, saving about 4 - 5 weeks in the overall product development timeline. This time savings can be crucial for companies to quickly introduce products to the market.

Is rapid tooling suitable for large - scale production?

Rapid tooling has both advantages and limitations for large - scale production. On the positive side, it allows for quick mold creation, which can be beneficial in the initial stages of large - scale production for rapid design iterations and getting the production line up and running faster. The ability to use a variety of materials also provides flexibility. However, it has limitations. The materials used in rapid tooling may not always have the same long - term durability and mechanical properties as traditional tool - making materials like high - grade steel, which are better suited for the high - stress environment of long - term, large - scale production. Also, the cost per unit of the mold may still be relatively high for large - scale production compared to mass - produced traditional molds, especially when considering the cost of 3D printing equipment and specialized materials.