Understanding Additive Manufacturing Solutions

Additive manufacturing solutions, commonly known as 3D printing, are a revolutionary approach to manufacturing. Instead of subtracting material from a larger block (like in traditional machining), additive manufacturing builds objects layer by layer from a digital model. Think of it like creating a cake. Traditional manufacturing is like carving a cake out of a large block of cake - you cut away the parts you don't need. In contrast, additive manufacturing is like building a cake by carefully placing one layer of icing, then a layer of sponge, and repeating, until the whole cake is formed.

This technology has been around for a few decades but has seen exponential growth in recent years. It uses a variety of materials, such as plastics, metals, ceramics, and even biological materials in some advanced applications. For instance, in the medical field, 3D printers can use biocompatible materials to create customized prosthetics or even tissue scaffolds for regenerative medicine.

Key Components of Additive Manufacturing Solutions

Machines

Additive manufacturing machines come in various types, each with its own set of features and optimal use cases.

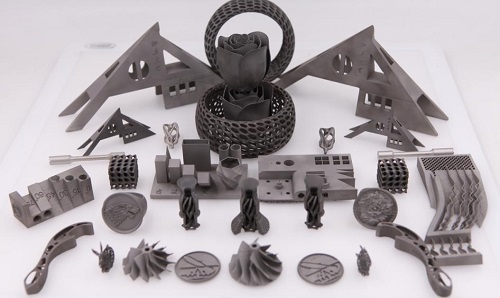

Metal 3D Printers: These are high - end machines designed for manufacturing metal components. They use technologies like Selective Laser Melting (SLM) or Electron Beam Melting (EBM). For example, the SLM machines use a high - power laser to melt metal powder layer by layer, creating highly detailed and strong metal parts. They are ideal for industries such as aerospace, where parts need to be lightweight yet extremely strong. Consider the following comparison of two metal 3D printers:

| Model | Build Volume (mm) | Laser Power (W) | Layer Thickness (μm) | Ideal for |

| Printer A | 250 x 250 x 325 | 400 | 20 - 100 | Small to medium - sized complex metal parts in aerospace and medical devices |

| Printer B | 500 x 500 x 400 | 500 | 30 - 150 | Larger metal components for automotive and industrial machinery |

Plastic 3D Printers: They are more common and cost - effective. Fused Deposition Modeling (FDM) printers, for instance, extrude melted plastic filament layer by layer. They are great for prototyping, small - scale production of plastic parts, and educational purposes. A typical desktop FDM printer might have a build volume of around 200 x 200 x 200 mm and can work with a variety of plastic filaments like PLA, ABS, and PETG.

Materials

The materials used in additive manufacturing are diverse, and choosing the right one is crucial for the success of a project.

- Metals: Stainless steel, titanium alloy, and aluminum alloy are frequently used. Stainless steel (e.g., 316L) offers excellent corrosion resistance and is often used in medical and food - processing equipment. Titanium alloy, known for its high strength - to - weight ratio, is a top choice for aerospace components. For example, in aircraft engines, titanium alloy parts can reduce weight while maintaining structural integrity.

- Plastics: PLA (Polylactic Acid) is a popular biodegradable plastic, commonly used in desktop 3D printing for its ease of use and relatively low cost. ABS (Acrylonitrile Butadiene Styrene) is more durable and heat - resistant, making it suitable for functional prototypes and parts that need to withstand mechanical stress.

- Ceramics: Alumina and zirconia ceramics are used when high - temperature resistance, hardness, and wear resistance are required. In the aerospace and electronics industries, ceramic 3D - printed parts can be used in components like heat shields and electronic insulators.

Optimizing materials can significantly enhance the quality of 3D - printed objects. For example, some metal powders are engineered to have a specific particle size distribution to ensure better melting and layer adhesion during the printing process.

Services

A comprehensive additive manufacturing solution often includes a suite of services.

- Design Optimization: Engineers can take a traditional design and optimize it for 3D printing. For example, they can use lattice structures to reduce weight while maintaining strength, or create complex internal channels that would be impossible to manufacture with traditional methods.

- Prototyping: Rapid prototyping allows companies to quickly create a physical model of their product design. This helps in early - stage testing, design validation, and getting feedback from stakeholders.

- Full - Scale Production: Once the design is finalized, additive manufacturing can be used for small - batch or even large - scale production. A case in point is a medical device company that used additive manufacturing to produce custom - fit orthopedic implants. By using 3D printing, they could create implants tailored to each patient's unique anatomy, reducing surgery time and improving patient recovery. This not only improved the quality of care but also increased the company's market share in the orthopedic implant market.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology sees great potential in additive manufacturing solutions. In custom - made production, additive manufacturing enables us to create highly customized products with complex geometries that are difficult to achieve through traditional manufacturing methods. This technology reduces production lead times, as we can quickly move from design to production without the need for complex tooling. For plastic and metal products, additive manufacturing also allows for the use of a wider range of materials, optimizing product performance. Overall, it provides a more flexible and efficient solution for meeting our customers' unique needs.

FAQ

What types of materials can be used in additive manufacturing?

Commonly used materials in additive manufacturing include plastics like PLA, ABS, and PETG, metals such as stainless steel, titanium alloy, and aluminum alloy, and ceramics like alumina and zirconia. The choice of material depends on the requirements of the final product. For example, if high strength and heat - resistance are needed, metals or ceramics might be preferred, while for quick and cost - effective prototyping, plastics are a great option.

How accurate are additive manufacturing solutions?

The accuracy of additive manufacturing solutions can vary. Generally, for desktop FDM plastic 3D printers, the accuracy is often in the range of ±0.1 - 0.4 mm. High - end industrial metal 3D printers can achieve much higher precision, with an accuracy of around ±0.05 - 0.2 mm. Factors affecting accuracy include the type of 3D printing technology used, the quality of the machine, the properties of the materials, and the complexity of the model.

Is additive manufacturing suitable for mass production?

Additive manufacturing can be suitable for mass production in some cases. For products with complex geometries or highly customized requirements, additive manufacturing can reduce costs and lead times compared to traditional manufacturing methods. However, for simple and high - volume products, traditional manufacturing techniques may still be more cost - effective due to the higher speed and lower per - unit cost of large - scale production. It's important to carefully evaluate the product design, production volume, and cost - benefit analysis to determine if additive manufacturing is the right choice for mass production.