What is a Rapid Prototyping Factory?

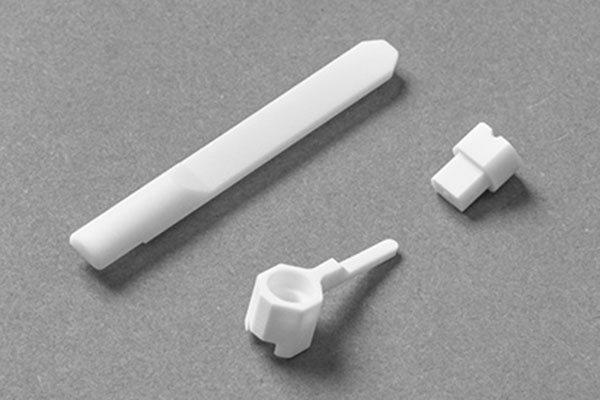

A rapid prototyping factory is a specialized manufacturing facility that focuses on quickly producing physical prototypes of products. It serves as a crucial link between the design phase and mass production. Using advanced technologies such as 3D printing, CNC machining, and injection molding, these factories can transform digital designs into tangible objects in a short time. For example, in the automotive industry, when a car manufacturer comes up with a new design for a car interior component, a rapid prototyping factory can create a prototype within days. This allows designers and engineers to test the form, fit, and function of the part before investing in expensive mass - production tooling.

The main function of a rapid prototyping factory is to accelerate the product development cycle. By quickly creating prototypes, companies can identify design flaws early, make necessary adjustments, and get their products to market faster. In the past, the prototyping process could take weeks or even months, but with the services of a rapid prototyping factory, this time can be significantly reduced. According to industry statistics, in some cases, the prototyping time can be cut by up to 80%, from an average of 6 - 8 weeks to just 1 - 2 weeks. This not only saves time but also reduces costs associated with design rework during later stages of production.

How to Choose the Right Rapid Prototyping Factory?

Choosing the right rapid prototyping factory is crucial for the success of your product development project. Here are some key factors to consider:

Experience and Expertise

- Industry Experience: Look for a factory with extensive experience in your specific industry. For instance, if you are in the medical device industry, a rapid prototyping factory that has previously worked on medical prototypes will understand the unique requirements such as biocompatibility and regulatory compliance. A factory with 10+ years of experience in rapid prototyping is more likely to have encountered and solved a wide range of problems, ensuring a smoother prototyping process for your project.

- Expertise of the Team: The factory's team should consist of skilled engineers, technicians, and designers. These professionals should be proficient in different prototyping technologies. For example, they should be able to optimize a 3D printing design to ensure the best possible quality and accuracy. Certifications held by the team members, such as those related to advanced manufacturing technologies, can also be a sign of their expertise.

Equipment and Technology

- Advanced Equipment: State - of - the - art equipment is essential for high - quality prototyping. A factory equipped with the latest 3D printers, like multi - material 3D printers that can create prototypes with different mechanical properties in a single build, can offer more design flexibility. CNC machines with high - precision spindles can produce complex and accurate parts. For example, a CNC milling machine with an accuracy of ±0.001mm can ensure that the prototypes meet tight tolerances.

- New Technology Adoption: A forward - thinking rapid prototyping factory will keep up with the latest technological trends. For example, the adoption of additive manufacturing techniques like binder jetting, which can produce high - volume prototypes quickly, can give you an edge in terms of speed and cost - effectiveness. The use of simulation software during the prototyping process can also help in predicting the performance of the prototype before it is physically made, saving time and resources.

Customer Service

- Communication Response Speed: The factory should respond promptly to your inquiries. Whether it's a question about the progress of your prototype or a request for a design change, a quick response time (ideally within 24 hours) is a sign of good customer service. Delays in communication can lead to project delays.

- Project Follow - up: A reliable factory will keep you informed about every stage of the prototyping process. They should provide regular updates on the status of your project, including any potential issues that may arise. For example, if there are delays due to equipment maintenance, they should communicate this to you immediately and provide a revised timeline.

- After - sales Support: Even after the prototype is delivered, the factory should be available to answer questions or provide support. This could include advice on how to test the prototype, or if there are any defects, they should be willing to work with you to resolve the issues, whether it's through re - printing or re - machining the parts.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the role of rapid prototyping factories. We believe that a reliable rapid prototyping factory is an essential partner in our product development process.

Cooperation Advantages: When collaborating with a rapid prototyping factory, we can quickly transform our innovative design concepts into physical samples. This allows us to conduct in - depth testing and optimization, reducing the risk of errors in mass production. For example, in a project involving the development of a new plastic - metal composite product, the rapid prototyping factory's quick turnaround time enabled us to make design adjustments promptly based on the prototype's test results, ensuring the final product met high - quality standards.

Service idea: At Yigu Technology, we also expect the rapid prototyping factory to offer comprehensive services. This includes not only high - quality prototyping but also professional advice on material selection, design optimization, and cost - effective solutions. A good rapid prototyping factory should be able to work closely with us, understand our unique requirements, and provide customized services to meet our specific needs. We value long - term partnerships with rapid prototyping factories that can grow with us and contribute to the continuous improvement of our products.

FAQ

Q1: What is the typical turnaround time for a prototype in a rapid prototyping factory?

The turnaround time for a prototype in a rapid prototyping factory can vary depending on several factors. For simple prototypes made with 3D printing, it can be as short as 1 - 3 days. For example, a small plastic part with a relatively simple shape can be printed and finished within a day if the design is already in a suitable format and the factory has available 3D printers. However, for more complex prototypes that involve CNC machining or multiple production steps, the time can be longer. CNC - machined prototypes may take 5 - 7 days. This is because CNC machining requires more precise programming, tool changes, and careful machining operations to achieve the desired accuracy and surface finish. Additionally, if the prototype involves multiple processes such as molding and post - processing like painting or polishing, the turnaround time can be extended to 1 - 2 weeks.

Q2: Can a rapid prototyping factory handle large - scale production?

While rapid prototyping factories are primarily known for their speed in creating prototypes, many can also handle small to medium - scale production. Some advanced rapid prototyping technologies like high - speed 3D printers and automated CNC machining setups can be scaled up for limited production runs. For instance, binder jetting 3D printing technology can produce a relatively large number of parts in a shorter time compared to traditional 3D printing methods, making it suitable for small - scale production. In terms of production capacity, a factory might be able to produce hundreds to thousands of units depending on the complexity of the part and the available equipment. The advantage of using a rapid prototyping factory for small - scale production is the ability to quickly adjust the design if needed, which is much more difficult and time - consuming in traditional large - scale manufacturing setups. However, for large - scale mass production, traditional manufacturing methods like injection molding in dedicated mass - production facilities are usually more cost - effective and efficient due to their high - volume capabilities.

Q3: How does a rapid prototyping factory ensure the accuracy of the prototypes?

Rapid prototyping factories use several methods to ensure the accuracy of prototypes. First, they regularly calibrate their equipment. For example, 3D printers are calibrated to ensure that the movement of the print head in all axes is precise, and the extrusion rate of the material is consistent. CNC machines are calibrated to maintain their high - precision spindle rotation and the accuracy of the axes' movement. The calibration process usually involves using precision measuring tools and following strict calibration procedures provided by the equipment manufacturers. Second, they have a strict quality control process. Before starting the production of a prototype, the design files are carefully checked for any errors or potential issues that could affect accuracy. During the production process, operators monitor the machines closely and take measurements at various stages. After the prototype is completed, it is inspected using high - precision measuring equipment such as coordinate measuring machines (CMMs). These machines can measure the dimensions of the prototype with extremely high accuracy, usually within ±0.01mm - ±0.1mm depending on the complexity of the part and the requirements. If any deviations from the design specifications are detected, the factory will take corrective actions, which may include re - machining or re - printing the part.