Understanding 3D Model Printing

What is 3D Model Printing?

3D model printing, also known as additive manufacturing, is a revolutionary technology that turns digital 3D models into tangible, three - dimensional objects. Instead of traditional manufacturing methods that often involve subtracting material (such as carving or milling), 3D printing builds objects layer by layer. For example, if you have a digital design of a small figurine on your computer, a 3D printer can transform this design into a physical plastic or metal figurine right in front of you. This technology has opened up a world of possibilities, allowing for the creation of complex geometries that were previously difficult or impossible to achieve with conventional manufacturing techniques. It has applications across various industries, from aerospace and automotive to healthcare and consumer products. In the aerospace industry, 3D - printed parts can reduce the weight of aircraft, improving fuel efficiency. In healthcare, customized prosthetics can be created to fit patients perfectly, enhancing their quality of life.

The Working Principle of 3D Printers

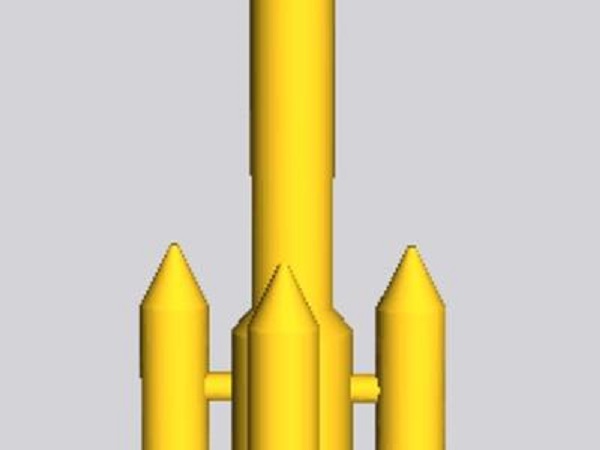

3D printers operate on a relatively straightforward principle, although the technology behind them is quite sophisticated. First, a 3D model is created using computer - aided design (CAD) software or obtained from a 3D scanner. This digital model is then sliced into thin cross - sections by the printer's software.

The printer then starts to build the object layer by layer. There are different types of 3D printing technologies, but most commonly, they use a nozzle or a print head. For instance, in fused deposition modeling (FDM), which is one of the most popular 3D printing methods, a spool of thermoplastic filament (such as PLA or ABS) is fed into the printer. The filament is melted in the hot end of the nozzle and extruded in a precise pattern onto a build platform. Each layer is deposited on top of the previous one, and as the layers stack up, the 3D object gradually takes shape.

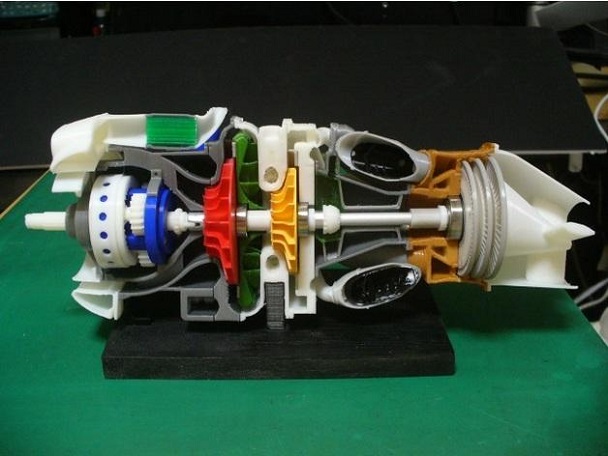

Another common technology is stereolithography (SLA). In SLA printers, a vat is filled with a photosensitive resin. A laser beam traces the cross - section of the object onto the surface of the resin, curing it and solidifying it into the desired shape. Layer by layer, the object is built up within the resin vat. Each layer is typically very thin, ranging from 0.1 mm to 0.05 mm in some high - end printers, which allows for the creation of highly detailed objects.

How to Choose the Right 3D Model Printing Service Near You

Finding the right 3D model printing service near you can be a game - changer, whether you're a hobbyist, a professional designer, or a business owner. Here are some key factors to consider:

Equipment and Technology

The equipment and technology used by a 3D printing service are crucial. Advanced printers can provide higher precision and better surface quality. For example, some high-end SLA printers can print models with extremely rich details, with layer thicknesses up to 0.05mm or even lower, which is very important for fields such as jewelry design and fine art printing. Industrial grade FDM printers perform well in printing large objects and components with high strength requirements, and can use a variety of high-performance materials such as carbon fiber reinforced plastics. When evaluating a service, ask about the types of 3D printers they have. A service that invests in the latest technology is more likely to be able to handle a wide range of projects and meet your quality expectations.

Material Options

A good 3D printing service should offer a diverse range of materials. Common 3D printing materials include plastics such as PLA and ABS, as well as metal materials such as aluminum alloy and stainless steel, ceramics, resins, etc. Different materials have different characteristics and are suitable for different application scenarios. For example, PLA is a popular, eco - friendly plastic that is easy to print with and is great for prototypes and decorative items. Metal materials, on the other hand, are ideal for functional parts that require high strength and durability, such as in the automotive or aerospace industries. The ability to choose from a wide variety of materials means you can get the best - suited material for your specific project.

Portfolio and Experience

Viewing cases and experiences of printing service providers is an effective way to evaluate their professional capabilities. A service with a rich portfolio has likely worked on different types of projects, from small, intricate figurines to large - scale industrial parts. For instance, if a company has successfully completed projects for the medical industry, they will have experience in dealing with the strict requirements of biocompatible materials and high - precision printing for prosthetics or surgical models. Experience also means they are more likely to anticipate and solve potential problems during the printing process.

Customer Reviews and Testimonials

Customer reviews and recommendations are important criteria for understanding the quality of printing services. Positive reviews often highlight aspects such as high - quality prints, on - time delivery, and excellent customer service. For example, customers might praise a service for its attention to detail in ensuring that the final 3D printed product exactly matches the original digital model. Negative reviews can also be informative, pointing out issues like poor print quality, long lead times, or unresponsive customer service. Reading through a range of reviews on platforms like Google Reviews or industry - specific forums can give you a well - rounded view of a 3D printing service's reputation.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the role of 3D model printing services. In product development, 3D printing offers a cost - effective and time - saving solution for creating prototypes. It allows us to quickly test design concepts, make modifications, and ensure the final product meets all requirements before mass production.

For custom products, 3D printing's ability to handle complex geometries and offer a wide range of materials perfectly aligns with our customers' diverse needs. Whether it's a unique plastic component with intricate details or a high - strength metal part, 3D model printing services can bring our designs to life accurately. This technology has significantly enhanced our flexibility and efficiency in serving our clients, enabling us to provide high - quality custom products in a shorter time frame.

FAQs about 3D Model Printing Service Near Me

What types of materials can be used for 3D printing?

Common 3D printing materials include plastics like PLA, ABS, PETG, and nylon; metals such as stainless steel, aluminum alloy, and titanium alloy; and resins like standard resin and photosensitive resin. PLA is biodegradable and easy to print, often used for prototypes and decorative items. Metals are suitable for high - strength and durable functional parts in industries like automotive and aerospace. Resins are great for creating highly detailed models with smooth surfaces, especially in jewelry and art - related projects.

How long does it usually take to complete a 3D printing project?

The time required to complete a 3D printing project depends on the complexity of the model and the performance of the printer. For a simple and small - sized model, it may only take a few hours, perhaps 2 - 3 hours on a relatively fast desktop 3D printer. However, for a large and complex model with intricate details, it could take several days. For example, a large - scale industrial part with complex internal structures might take 2 - 3 days to print on an industrial - grade 3D printer.

Can I get design assistance if I only have a rough idea for my 3D model?

Many 3D printing services offer design assistance. If you only have a rough concept, their in - house designers or engineers can help transform your idea into a printable 3D model. They can use CAD software to create a detailed digital model based on your description, sketches, or even simple 2D drawings. This service is especially beneficial for those who are not familiar with 3D design software but have a creative vision for their 3D - printed objects.