The Appeal of Skull Masks

Skull masks have a long - standing presence in various aspects of human culture, art, and entertainment, carrying deep - seated symbolic meanings.

In Cultural and Traditional Celebrations

One of the most well - known occasions for the use of skull masks is Halloween. This spooky festival, celebrated in many Western countries on October 31st, is incomplete without skull - themed decorations and masks. People, especially children and teenagers, dress up in costumes and wear skull masks to mimic the dead, adding an air of mystery and fright to the festivities. The skull, in this context, represents mortality, the afterlife, and the supernatural. It has become an iconic symbol of the holiday, with stores stocking a wide variety of skull masks in different styles, from realistic - looking replicas of human skulls to more cartoonish and exaggerated designs.

Carnivals around the world also feature skull masks prominently. For example, in the Day of the Dead (Día de los Muertos) celebrations in Mexico, skull masks (known as "calaveras") are an integral part of the festivities. This holiday is a time to remember and honor deceased loved ones. The masks, often decorated with bright colors, flowers, and intricate patterns, transform the wearers into a celebration of life and death. They are a way to show that death is not something to be feared but rather a natural part of the life cycle.

In the Realm of Art and Fashion

Skull masks have made their mark on the fashion runways and art galleries. In the fashion industry, designers often incorporate skull - mask elements into their collections to make a bold statement. High - end fashion shows may feature models strutting down the catwalk wearing avant - garde skull masks that blend fashion and art. These masks can be made from luxurious materials such as leather, silk, or even precious metals, and are adorned with crystals, feathers, or embroidery. They represent rebellion, edginess, and a departure from the norm, attracting fashion - forward individuals who want to stand out.

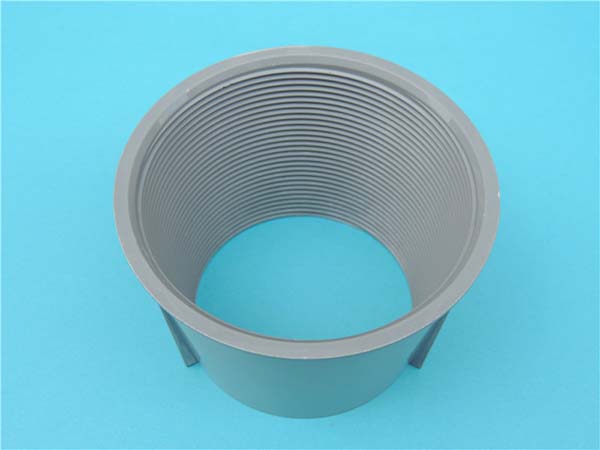

In the art world, skull masks are a popular subject for artists. Sculptors may create detailed 3D - printed skull masks as a form of expression, exploring themes of identity, the human condition, and the passage of time. Painters may use skull masks in their works to convey a sense of mystery, danger, or the macabre. These artistic interpretations not only showcase the creativity of the artists but also invite viewers to think about the deeper meanings associated with the skull.

In Film, Television, and Gaming

Skull masks are frequently seen in the entertainment industry. In movies and TV shows, villains or characters with a dark, mysterious persona often don a skull mask to enhance their menacing appearance. For instance, in some superhero movies, the antagonist might wear a skull mask to strike fear into the hearts of the heroes and the audience. In the world of gaming, skull - masked characters are also prevalent. They can be powerful bosses that players must defeat or playable characters with unique abilities. These virtual skull masks add an extra layer of excitement and challenge to the gaming experience, as players interact with characters that are both visually striking and often possess formidable powers.

Step - by - Step Guide to 3D Printing a Skull Mask

Designing the Mask

The first crucial step in 3D printing a skull mask is designing the digital model. There are several user - friendly software options available, depending on your skill level and the complexity of the design you envision.

Tinkercad: This is an excellent choice for beginners. It has a simple, intuitive interface that allows you to create 3D models using basic shapes like cubes, spheres, and cylinders. To design a skull mask in Tinkercad, start by importing a basic head - shaped object. You can then use the "hole" and "union" functions to carve out the details of the skull, such as the eye sockets, nasal cavity, and teeth. For added details like cracks or a weathered look, you can use the "textures" or "brushes" features available in the software.

Blender: A more advanced but highly powerful option. Blender is a professional - grade 3D modeling software with a steep learning curve but offers limitless creative possibilities. First, create a basic cube and then use the "subdivision surface" modifier to smooth it out into a more organic shape. Next, use sculpting tools like "dynamic topology" to start shaping the cube into a skull. Tools such as "clay strips" can be used to build up the details of the skull, while "smooth" and "rake" tools can be used to refine the surface. Once the basic skull shape is complete, you can add more intricate details like the sutures on the skull or the individual teeth by using the "retopology" and "normal map baking" techniques.

Preparing the 3D Printer

Before starting the print, proper preparation of the 3D printer is essential to ensure a successful outcome.

- Calibration: This is a crucial step. Most 3D printers have an auto - calibration feature, but manual calibration can also be done. For FDM printers, calibration involves adjusting the bed level to ensure that the nozzle is at the correct distance from the build platform. A mis - calibrated bed can lead to issues such as the first layer not adhering properly or the print being too close or too far from the bed, resulting in a failed print.

- Selecting Print Parameters:

- Layer Height: A smaller layer height, such as 0.1mm, will result in a smoother print but will also increase the print time. For a skull mask, a layer height of 0.15 - 0.2mm can be a good balance between print quality and time.

- Print Speed: A slower print speed, around 40 - 60mm/s, can improve the quality of the print by allowing the filament to cool properly between layers. However, if you're on a time crunch, you can increase the speed to 80 - 100mm/s, but be aware that this may lead to a slightly rougher finish.

- Temperature: For PLA filament, a nozzle temperature of 200 - 210°C is typically recommended, while for ABS, it's around 230 - 250°C. The bed temperature for PLA can be around 60 - 65°C, and for ABS, it's usually 90 - 110°C.

Printing Process

During the printing process, it's important to monitor the progress closely.

- Initial Layers: The first few layers are crucial. Make sure the filament is extruding properly and that the layers are adhering well to the build platform. If the first layer is not laid down correctly, the entire print may fail. You can watch for any signs of the nozzle skipping, the filament not sticking, or the layer being too thin or too thick.

- Monitoring for Issues: Keep an eye out for common problems. One of the most common issues is a clogged nozzle. If the flow of filament suddenly stops or becomes inconsistent, it could be a sign of a clog. You may need to stop the print, heat up the nozzle, and try to clear the clog using a nozzle cleaning tool or a thin wire. Another issue is warping, especially with ABS filament. To prevent warping, you can use a heated bed, a build plate adhesive like glue stick or hairspray, or print a brim around the model to help with adhesion.

Post - Processing

After the print is complete, post - processing is required to make the skull mask look its best.

- Removing Support Structures: If your design required support structures during printing (which is often the case for overhanging parts of the skull mask), carefully remove them. You can use pliers, cutters, or a sharp knife to gently separate the supports from the main model. Be careful not to damage the mask while doing this.

- Sanding and Finishing: Use sandpaper of different grits to smooth out any rough surfaces. Start with a coarse grit, like 80 - 120, to remove any large bumps or imperfections, and then move on to finer grits, such as 400 - 800, for a smoother finish. You can also use a dremel tool with a sanding attachment for more precise sanding.

- Painting: Once the mask is smooth, you can paint it. Acrylic paints work well for 3D - printed objects. You can use a spray paint for an even coat or a brush for more detailed painting. For a realistic skull look, start with a base coat of off - white or bone - colored paint. Then, use darker colors like brown or gray to add shadows and highlights to give the mask a more three - dimensional and realistic appearance.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology acknowledges the potential of 3D printing in creating skull masks. The flexibility in design that 3D printing offers is a significant advantage. Designers can bring their most intricate and unique skull mask concepts to life without the limitations of traditional manufacturing molds. For small - batch production, 3D printing can be cost - effective as it reduces the need for expensive tooling.

However, there are also limitations. The range of materials available for 3D printing, especially when aiming for specific properties like high - strength or unique textures, can be restricted compared to traditional plastic and metal manufacturing. In terms of large - scale production, the speed of 3D printing is currently much slower than mass - production techniques.

In the future, Yigu Technology believes that combining 3D printing with traditional manufacturing processes could optimize skull mask production. For example, 3D printing could be used for creating prototypes or custom - designed parts, while traditional methods handle the mass production and finishing touches. This way, the best of both worlds can be achieved, ensuring high - quality skull masks that meet various market demands.