What is 3D Printing Technology in Construction?

3D printing technology in construction, also known as additive manufacturing in the building industry, is a revolutionary approach that has been gradually transforming the traditional construction processes. This technology allows for the creation of physical structures by layering materials based on a digital design.

The process begins with the use of computer - aided design (CAD) software. Designers and architects use this software to create a detailed three - dimensional model of the building or construction component. This model serves as the digital blueprint for the entire 3D printing process. For example, if a company wants to build a small 3D - printed house, the architects first use CAD software to design every aspect of the house, including the layout of rooms, the shape of the walls, and the position of doors and windows.

Once the 3D model is created, it is then sent to a 3D printer specifically designed for construction purposes. These printers are much larger and more robust than the regular desktop 3D printers used in other industries. Construction 3D printers can handle a variety of materials, the most common being concrete - like mixtures.

The printer then starts the process of building the structure layer by layer. It extrudes or deposits the building material in a precise pattern according to the digital model. Each layer is carefully laid on top of the previous one, gradually building up the three - dimensional object. The thickness of each layer can vary depending on the complexity of the design and the capabilities of the printer, but it is typically in the range of a few millimeters. For instance, when printing a wall, the printer will start from the bottom and work its way up, layer by layer, until the full - height wall is formed.

This technology enables the construction of complex geometries that would be extremely difficult or costly to achieve using traditional construction methods. Traditional construction often relies on pre - fabricated components or on - site manual labor to shape and assemble materials, which limits the complexity of the structures that can be built. In contrast, 3D printing technology in construction breaks these limitations, opening up new possibilities for architectural design and construction innovation.

Applications of 3D Printing Technology in Construction

Residential Construction

In the field of residential construction, 3D printing technology has shown great potential. For example, ICON, a company based in Texas, USA, has been using 3D printing to build low - cost housing. Their 3D - printed homes are not only more affordable but also constructed much faster compared to traditional methods. A single - family 3D - printed home by ICON can be completed in a relatively short time, reducing the overall construction time from months to just a few weeks. These homes are designed to meet basic living needs with a focus on simplicity and functionality, making them an ideal solution for affordable housing projects. The use of 3D printing allows for more precise material usage, reducing waste and further cutting down costs. This approach has the potential to address the global housing shortage issue, especially in areas with high demand for affordable housing.

Commercial Construction

3D printing technology is also making inroads into commercial construction. The "3D - Printed Building" project in the Netherlands is a prime example. This project demonstrated the use of 3D printing to create office buildings and commercial spaces. The 3D - printed structures feature unique and complex designs that would have been extremely difficult and costly to achieve through traditional construction methods. These commercial buildings not only stand out for their aesthetic appeal but also offer enhanced functionality. For instance, the interior spaces can be customized more freely according to the specific needs of businesses, such as creating open - plan offices or flexible retail spaces. Additionally, the use of 3D printing in commercial construction can lead to faster project completion times, enabling businesses to start operations sooner and reduce the time to market for new commercial developments.

Infrastructure Construction

Infrastructure construction is another area where 3D printing technology is being applied. Some cities in China have started to use 3D printing technology to build bridges and roads. 3D - printed bridges can be designed with optimized structures, providing better load - bearing capacity and durability. The process of 3D - printing a bridge is more efficient as it can be pre - fabricated off - site and then assembled on - site, minimizing the disruption to traffic during construction. In road construction, 3D - printed concrete can be used to create custom - designed road surfaces with improved drainage and skid - resistance properties. This technology also reduces the amount of construction waste generated during infrastructure projects, making it a more sustainable option for building the essential structures that support urban and rural development.

Artistic and Cultural Buildings

3D printing has added a new dimension to the construction of artistic and cultural buildings. Artists and architects are using this technology to create unique art installations and cultural venues. For example, a 3D - printed museum might have walls with intricate patterns and shapes that tell a cultural story, or an art gallery could have 3D - printed display structures that are both functional and visually stunning. These 3D - printed elements can be made from a variety of materials, including recycled plastics and specialized resins, which not only adds to the artistic value but also contributes to environmental sustainability. The ability to create one - of - a - kind designs through 3D printing makes it possible to build cultural buildings that are truly representative of the local culture and heritage, while also pushing the boundaries of architectural creativity.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology recognizes the vast potential of 3D printing technology in construction. The technology opens up new possibilities for material innovation. We believe that by collaborating with construction companies, we can develop specialized plastic and metal - based materials suitable for 3D printing in construction. These materials could offer enhanced strength, durability, and unique properties, such as self - healing capabilities or better insulation.

Moreover, 3D printing enables high - level customization. Yigu Technology can leverage its expertise in custom - made products to create unique construction components. Whether it's intricate architectural details or specialized parts for a specific building function, we can produce components that meet the exact requirements of construction projects, reducing the need for mass - production of standardized parts and minimizing waste. This not only benefits individual construction projects but also contributes to the overall development of the construction industry towards more sustainable and innovative practices.

FAQs about 3D Printing Technology in Construction

What are the main materials used in 3D printing for construction?

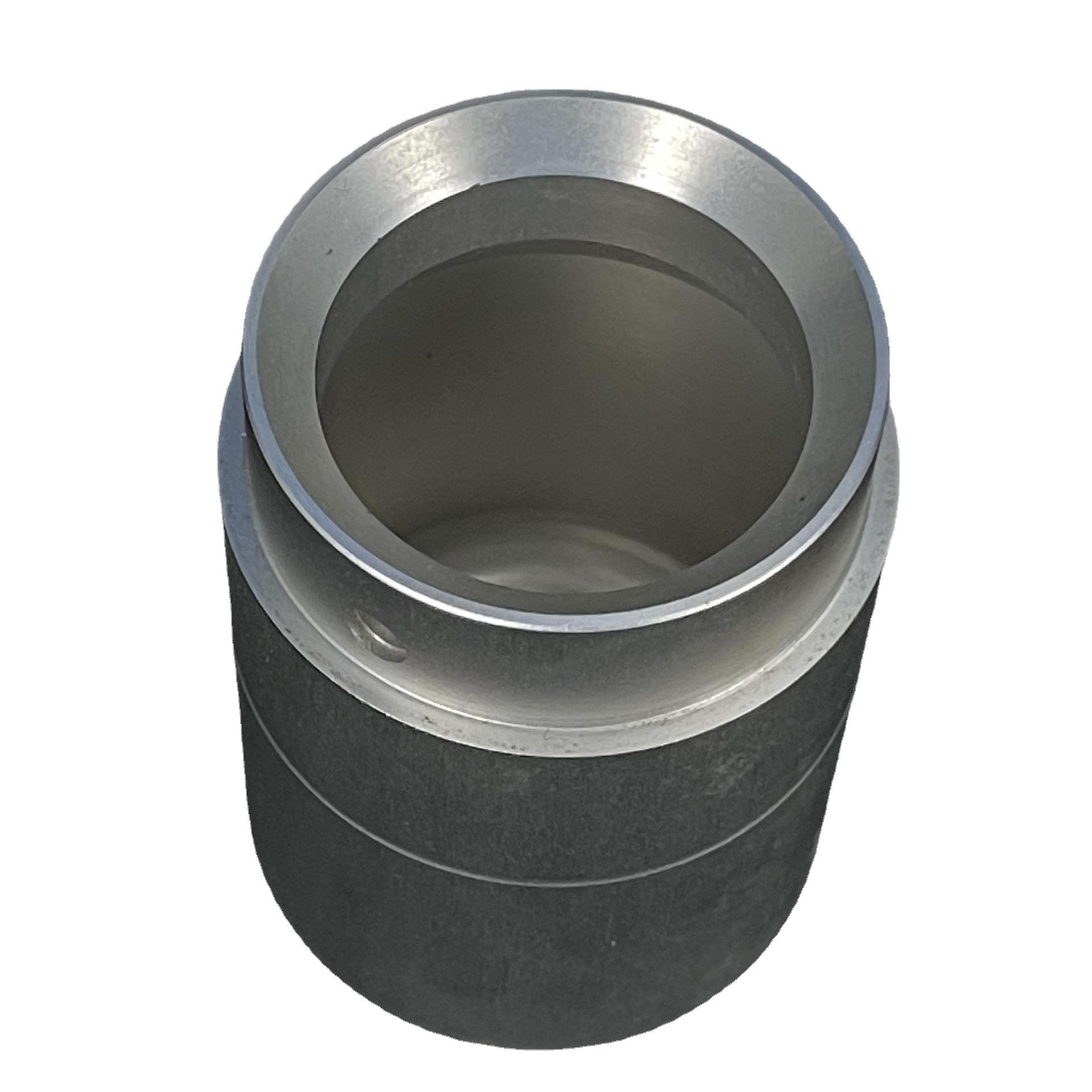

The main materials used in 3D printing for construction include concrete, plastic, and metal. Concrete is a popular choice due to its strength and durability. Special - formulated concrete mixtures are designed to be extrudable through the 3D printer's nozzle while maintaining the necessary structural properties. For instance, some 3D - printed concrete structures can withstand high compressive forces, making them suitable for building load - bearing walls.

Plastics like acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) are also used, especially for smaller - scale components or in applications where lightweight materials are required. They are easy to print with and can be used for creating architectural models or non - structural decorative elements.

Metals such as stainless steel, aluminum, and titanium are used for high - strength and specialized applications. Metal 3D - printed components can be used in areas where extreme durability and corrosion resistance are needed, like in the construction of bridges or industrial buildings. Each material has its unique characteristics and is chosen based on the specific requirements of the construction project.

How does 3D printing technology ensure the structural integrity of buildings?

3D printing technology ensures the structural integrity of buildings in several ways. First, the digital design phase allows for in - depth structural analysis. Using advanced software, engineers can simulate how the 3D - printed structure will perform under different loads, such as wind, seismic, and gravitational forces. Based on the simulation results, the design can be optimized to distribute stresses evenly throughout the structure.

During the printing process, the printer precisely controls the deposition of materials layer by layer. This precise control ensures that each layer is placed accurately, following the designed pattern. The materials bond well with each other, creating a continuous and stable structure. Additionally, some 3D - printing techniques can reinforce the structure during the printing process. For example, adding internal support structures or using composite materials with enhanced strength properties.

What is the future development trend of 3D printing technology in construction?

The future development trend of 3D printing technology in construction is promising. Technological advancements will continue to improve the speed, precision, and size capabilities of 3D printers. New materials with better performance, such as self - healing materials and high - strength lightweight composites, will be developed.

Integration with smart building technologies is another trend. 3D - printed buildings will likely be integrated with sensors and IoT devices to create smart buildings. These buildings can monitor their own structural health, energy consumption, and environmental conditions, and make automatic adjustments to optimize performance.

Global application expansion is also expected. As the technology becomes more affordable and accessible, more countries and regions will adopt 3D printing in construction, helping to address housing shortages and infrastructure needs worldwide. Moreover, 3D printing will contribute to sustainable development in construction. By reducing material waste and energy consumption during the building process, it aligns with the global push for more environmentally friendly construction practices.