Picture this: Your production line grinds to a halt because a mold has cracked under pressure, or parts are coming out with inconsistent dimensions due to poor material stability. For manufacturers, these issues aren’t just frustrating—they hit the bottom line hard. That’s where Mold Making Cr12MoV (D2) steel comes in. Renowned for its balanced performance, Cr12MoV (equivalent to AISI D2) bridges the gap between extreme hardness and practical toughness, making it a go-to for demanding mold applications. In this guide, we’ll explore how Cr12MoV (D2) solves common manufacturing headaches, from short tool life to imprecise outputs, and why it’s a staple in precision mold making.

Material Composition and Properties of Cr12MoV (D2)

The magic of Cr12MoV (D2) lies in its carefully engineered material composition and properties, which work together to deliver reliable performance in tough conditions:

- Chromium content: At 11-13%, the high chromium content forms hard chromium carbides, the backbone of D2’s exceptional wear resistance. These carbides act like tiny armor plates, resisting abrasion during repeated use—critical for high-volume stamping and extrusion.

- Molybdenum content: With 0.7-1.2% molybdenum, Cr12MoV gains improved hardenability and toughness. This element helps reduce brittleness, making D2 less prone to cracking than higher-carbon steels like AISI D3.

- Vanadium content: A small but mighty 0.8-1.2% vanadium forms fine vanadium carbides, enhancing wear resistance further and refining the steel’s grain structure for better dimensional stability during heat treatment.

- Carbon content: 1.4-1.6% carbon ensures D2 achieves high hardness, with a hardness range of 57-62 HRC after heat treatment. This sweet spot balances cutting edge retention with enough flexibility to avoid sudden failure.

- Thermal stability: D2 maintains its hardness at temperatures up to 450°F (232°C), outperforming many cold work steels. This makes it suitable for applications where friction generates moderate heat, like continuous stamping.

- Corrosion resistance: Thanks to its chromium content, D2 offers better corrosion resistance than plain carbon steels. It can withstand humid workshops and short-term exposure to coolants, though long-term storage still requires rust protection.

Applications in Mold Making: Where Cr12MoV (D2) Excels

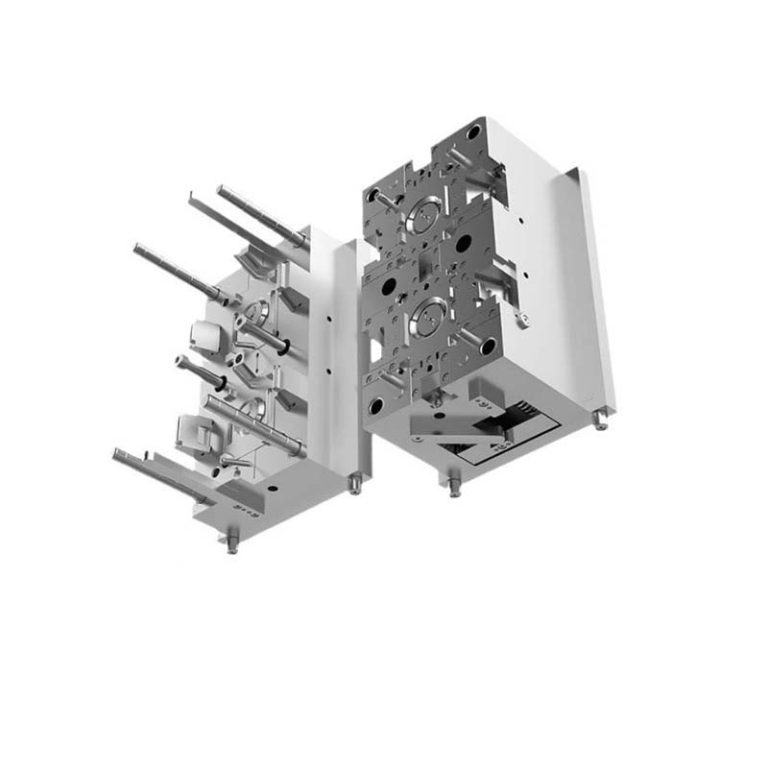

Cr12MoV (D2) isn’t just a one-trick pony—it shines across a range of applications in mold making where precision and durability matter most:

- Cold work tooling: From blanking dies to forming tools, D2 is a workhorse. Its ability to hold tight tolerances (±0.0005 inches) makes it ideal for producing consistent parts in high-volume runs.

- Plastic injection molds: For molding abrasive plastics (filled with glass or mineral fibers), D2’s wear resistance prevents premature surface degradation. Manufacturers report up to 50% longer mold life compared to standard steels.

- Stamping dies: In automotive stamping, where thousands of parts are produced daily, D2’s durability reduces downtime. A D2 stamping die can handle 300,000-800,000 cycles before needing reconditioning—double the life of O1 steel dies.

- **Punuble the life of O1 steel dies.

- Punches and shears: The sharp edge retention of D2 ensures clean cuts in sheet metal and other materials. A D2 punch used in 16-gauge steel cutting stays sharp for 40,000+ cycles, vs. 20,000 cycles for A2.

- High-precision molds: Medical device molds and electronics components require tight tolerances, and D2’s dimensional stability delivers. After heat treatment, it experiences less than 0.0002 inches of distortion per inch, critical for micro-molding applications.

- Progressive dies: These complex dies perform multiple operations in one pass, and D2’s balance of hardness and toughness resists the varied stresses involved. It’s a top choice for progressive dies in appliance and electronics manufacturing.

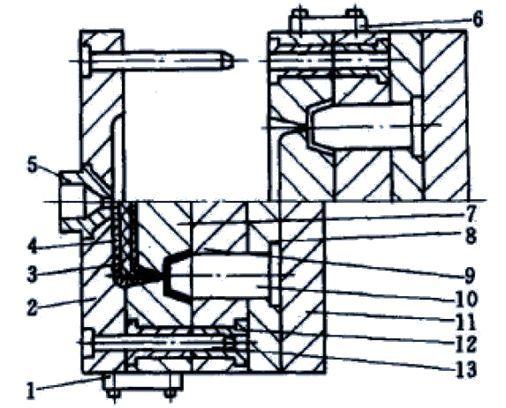

Heat Treatment and Processing of Cr12MoV (D2)

To unlock D2’s full potential, heat treatment and processing must be precise. Even small mistakes can lead to subpar performance:

- Annealing process: Before machining, D2 is annealed to 180-220 HB for easier cutting. Heat to 1500-1550°F (815-845°C), hold 2-4 hours, then cool slowly (≤50°F/hour). This reduces internal stresses and improves machinability.

- Hardening temperatures: Heat to 1850-1900°F (1010-1038°C) and hold 30-60 minutes. This temperature range ensures all carbides dissolve evenly, which is key for uniform hardness. Overheating (above 1950°F) causes grain growth and brittleness.

- Quenching methods: Oil quenching is standard, cooling D2 rapidly to form martensite without excessive distortion. For complex molds, vacuum quenching minimizes oxidation, reducing post-processing polishing time by 20-30%.

- Tempering cycles: Temper at 300-400°F (150-204°C) for 1-2 hours, then air cool. A second tempering cycle (same parameters) ensures complete transformation of retained austenite, boosting toughness and stability.

- Surface treatments: Nitriding adds a 5-10 micron hard layer, increasing surface hardness to 65-70 HRC and improving wear resistance by 40%. PVD coatings (e.g., TiCN) reduce friction, ideal for plastic injection molds where material flow is critical.

- Machinability: Annealed D2 is moderately machinable, but its carbide content wears tools quickly. Use carbide inserts with a negative rake angle and cutting speeds of 40-70 SFM. Coolant is essential to prevent overheating.

- EDM (Electrical Discharge Machining): D2 handles EDM well, but the recast layer (0.0001-0.0003 inches) must be removed via polishing or etching to avoid cracking. This is especially important for high-stress applications like cold forging dies.

Performance and Durability: What D2 Delivers

When it comes to performance and durability, Cr12MoV (D2) consistently meets the demands of high-stakes manufacturing:

- Mold life expectancy: In plastic injection molds, D2 lasts 500,000-1,000,000 cycles for non-abrasive plastics and 300,000-500,000 cycles for glass-filled materials—outperforming A2 by 30-50%.

- Resistance to chipping: D2’s toughness reduces chipping risk compared to higher-hardness steels like D3. Proper tempering (350°F for 2 hours) ensures it can absorb minor impacts without failure.

- Edge retention: In abrasive environments, D2 holds an edge 20-30% longer than A2. For example, in cold extrusion of aluminum, a D2 die maintains its profile 25% longer than an A2 die.

- Cost-effectiveness: While D2 costs 20-30% more than O1 upfront, its longer life lowers total cost of ownership. For a high-volume stamping operation, switching to D2 can reduce annual tooling costs by 15-20%.

- Maintenance requirements: Regular cleaning and light polishing keep D2 molds in top shape. Reconditioning (grinding and re-hardening) can extend life by 2-3x, making it a sustainable choice for long-term production.

Comparison with Other Tool Steels

How does Cr12MoV (D2) stack up against alternatives? Here’s a clear breakdown:

| Steel Grade | Hardness (HRC) | Wear Resistance | Toughness | Cost (Relative) | Best For |

| Cr12MoV (D2) | 57-62 | Very Good | Good | Medium-High | Balanced performance (stamping, injection molds) |

| AISI D3 | 58-64 | Excellent | Low | Medium | High-wear, low-impact (blanking dies) |

| SKD11 (Japanese) | 56-61 | Very Good | Good | Medium-High | Precision molds (electronics) |

| A2 | 57-61 | Good | Very Good | Medium | High-impact (forging dies) |

| Powder metallurgy (ASP-60) | 60-65 | Excellent | Good | Very High | Ultra-high-wear (metal forming) |

- D2 vs. D3: D3 offers higher wear resistance but lower toughness, making it prone to chipping in impact-heavy applications. D2 is more versatile, handling both wear and moderate impact.

- D2 vs. SKD11: SKD11 is nearly identical in composition but often has tighter impurity controls, making it slightly more consistent. However, D2 is more readily available globally at a similar price.

- Cost comparison: D2 costs less than powder metallurgy steels (e.g., ASP-60) but more than A2 or O1. Its balance of properties makes it the best value for most medium-to-high-volume precision applications.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology relies on Cr12MoV (D2) for its versatility and reliability. We’ve found it to be the ideal middle ground for clients needing both precision and durability—whether for automotive stamping dies or medical device molds. Our in-house heat treatment experts optimize D2’s properties for each application, ensuring hardness and toughness are balanced to meet specific production demands. For clients transitioning from lower-grade steels, switching to D2 typically reduces tooling costs by 20-30% over a year, thanks to longer mold life and fewer replacements.

FAQs

- Can Cr12MoV (D2) be used for high-impact applications?

D2 offers moderate toughness, making it suitable for low-to-moderate impact uses (e.g., stamping). For high-impact applications like heavy forging, A2 steel is a better choice due to its superior toughness.

- How does D2 perform in corrosive environments?

D2 has moderate corrosion resistance, suitable for humid workshops and short-term coolant exposure. For highly corrosive environments (e.g., marine parts), consider stainless tool steels instead.

- What’s the best way to extend D2 mold life?

Regular cleaning, proper storage (with rust inhibitors), and timely reconditioning (grinding and re-tempering) are key. Applying a PVD coating can also reduce wear and extend life by 30-40%.