Manufacturers working with high-temperature plastics or thin-walled parts often struggle with long cooling times, which slow production and increase costs. Even with aluminum molds, cooling can account for 50-70% of the total cycle time, leading to bottlenecks in high-volume production. For parts with complex geometries or tight tolerances, uneven cooling can also cause warping or dimensional inconsistencies, resulting in costly scrap. This is where copper alloys transform mold making. With thermal conductivity 2-3x higher than aluminum, copper alloys drastically reduce cooling times, solving the critical pain points of cycle time and part quality. In this guide, we’ll explore how copper alloys excel in demanding molding applications, their unique properties, and how to leverage their advantages effectively.

Introduction to Copper Alloys in Mold Making

Copper alloys for mold making are specialized materials valued for their exceptional thermal conductivity and versatility in high-performance applications:

- Definition: These are copper-based alloys, blended with elements like beryllium, tungsten, or nickel, to enhance strength, hardness, and wear resistance while retaining copper’s excellent thermal conductivity.

- Types of copper alloys: The most common grades include beryllium copper (C17200, C17510), copper-tungsten (CuW70, CuW80), and chromium copper (C18200). Beryllium copper is prized for its strength and conductivity, while copper-tungsten offers high heat resistance, and chromium copper balances conductivity and machinability.

- Standard specifications: Copper alloys for molds adhere to ASTM B196 (beryllium copper) and ASTM B760 (copper-tungsten) standards, ensuring consistent chemical composition and performance. For example, C17200 contains 1.8-2.0% beryllium and 0.2-0.4% cobalt for optimal strength.

- Supplier brands: Leading suppliers include Materion (USA), NGK Metals (Japan), and Chinese manufacturers like Jiangxi Copper. These brands offer copper alloys in rods, plates, and custom shapes tailored for mold inserts and components.

- Industry usage: Copper alloys are used in 15-20% of high-performance molds, particularly in areas requiring rapid cooling—such as thin-walled electronics parts, automotive lighting, and medical devices. They’re often used as inserts in steel or aluminum molds to target cooling in critical areas.

- Comparison with other mold materials: Compared to aluminum, copper alloys conduct heat 2-3x faster (200-350 W/m·K vs. 160-200 W/m·K) but are 30-50% more expensive and harder to machine. They’re softer than steel but offer superior cooling, making them ideal for thermal management in precision applications.

Properties of Copper Alloys

The properties of copper alloys make them indispensable for thermal management in mold making:

- High thermal conductivity: Beryllium copper (200-250 W/m·K) and copper-tungsten (200-350 W/m·K) far outperform aluminum and steel, enabling 30-50% faster cooling times. This reduces injection molding cycle times by 20-30% for thin-walled parts.

- High electrical conductivity: Copper alloys conduct electricity 2-3x better than aluminum, making them suitable for molds requiring in-mold heating or sensors, such as those used in thermoset molding.

- Good corrosion resistance: Most copper alloys resist corrosion from water-based coolants and mild chemicals, though they can tarnish. Passivation or plating (e.g., nickel) enhances resistance in humid environments.

- High strength (for copper-based materials): Beryllium copper achieves a tensile strength of 1,100-1,300 MPa after heat treatment—comparable to some steels—making it suitable for high-pressure molding (up to 20,000 psi).

- Machinability: Copper alloys machine well but require sharp tools due to their ductility. Beryllium copper machines faster than copper-tungsten, with cutting speeds of 100-150 SFM—slower than aluminum but manageable with carbide tools.

- Thermal expansion: Copper alloys expand more than steel (16-18 × 10⁻⁶/°C vs. 11-12 × 10⁻⁶/°C) but less than aluminum. This requires careful design to avoid fit issues in multi-material molds.

- Grain structure: Copper alloys have a fine, uniform grain structure, which ensures consistent thermal conductivity and machinability. This structure minimizes hot spots in the mold, preventing part warping.

Applications of Copper Alloys in Mold Making

Copper alloys excel in applications where rapid cooling and precision are critical:

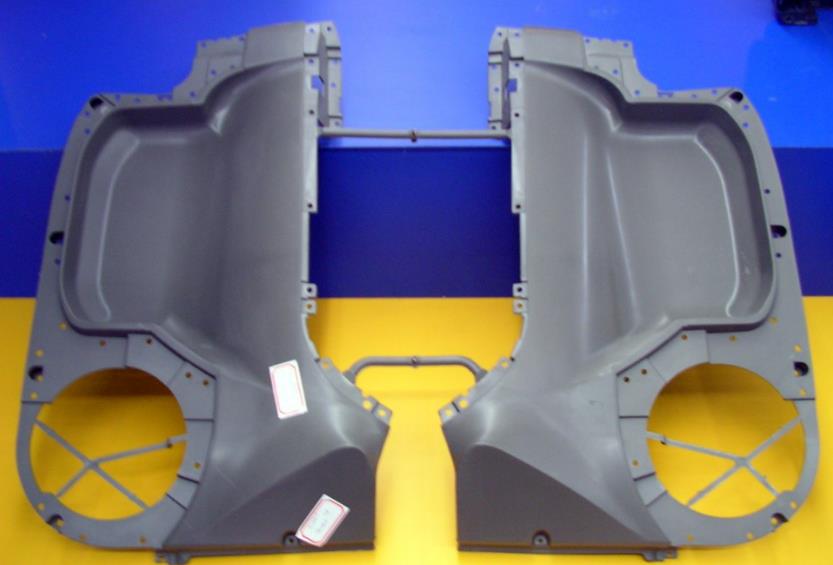

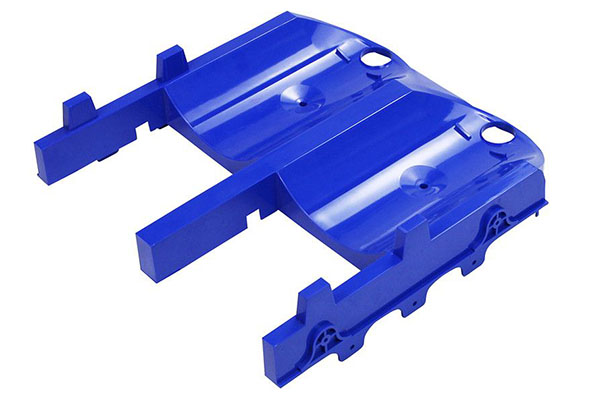

- Injection molding inserts: Copper alloy inserts are embedded in steel or aluminum molds to cool thin-walled parts (e.g., smartphone casings, laptop components) where uniform cooling is essential to prevent warping.

- High-precision molds: For parts with tight tolerances (±0.0001 inches), such as optical lenses or microelectronics, copper alloys’ rapid cooling ensures dimensional stability across production runs.

- Automotive molds: Copper inserts in automotive lighting molds (e.g., headlight housings) speed cooling of complex geometries, reducing cycle times and improving part consistency.

- Consumer electronics molds: Molds for 5G device components and wearable tech use copper alloys to cool heat-sensitive parts, ensuring they maintain their shape during molding.

- Medical device molds: Copper alloys’ corrosion resistance and rapid cooling make them suitable for molds producing thin-walled medical parts (e.g., syringes, catheter components) where precision and biocompatibility are key.

- Prototype molds: For testing cooling strategies in new designs, copper alloy inserts allow engineers to validate thermal performance before committing to full production molds.

Machining and Fabrication of Copper Alloys

Machining and fabrication of copper alloys require attention to their ductility and thermal properties:

- Precision machining: Copper alloys cut best with carbide tools due to their softness and tendency to gall. Use high cutting speeds (100-150 SFM) and light feeds to minimize tool wear, with coolant to prevent heat buildup and chip welding.

- CNC milling: 3-axis and 5-axis CNC milling achieve tight tolerances (±0.0002 inches) in copper alloys, though tool deflection is a risk due to their ductility. Rigid setups and sharp tools reduce this issue.

- EDM (Electrical Discharge Machining): EDM works well for intricate details in copper alloys, with their high conductivity requiring adjusted parameters (lower current) to prevent electrode wear. The process produces clean edges suitable for high-precision inserts.

- Grinding: Silicon carbide wheels are recommended for grinding copper alloys, with light pressure to avoid clogging. A 400-grit wheel achieves Ra 0.05 μm, suitable for most mold surfaces.

- Surface finishing: Copper alloys polish to a smooth finish (Ra 0.02-0.05 μm) with 600-grit sandpaper and a buffing wheel. Plating with nickel or chrome can improve wear resistance and prevent tarnishing.

- Machining challenges: Copper alloys tend to form long, stringy chips that 缠结刀具 (tangle tools). Using chip breakers and high-pressure coolant solves this, maintaining surface quality and tool life.

Maintenance and Repair of Copper Alloy Molds

Proper maintenance and repair ensure copper alloy molds retain their thermal conductivity and precision:

- Mold cleaning: Clean copper alloy surfaces with mild detergents and soft brushes to remove plastic residue. Avoid abrasive cleaners, which can scratch the surface and reduce thermal conductivity.

- Surface treatment: Plating with nickel (2-5 μm thick) enhances wear resistance and prevents tarnishing, extending insert life by 30-40% in high-volume production.

- Repair welding: Beryllium copper can be TIG welded with matching filler wire, though post-weld heat treatment is needed to restore strength. This is critical for repairing worn or damaged inserts.

- Preventive maintenance: Inspect copper inserts for cracks or wear monthly, especially in high-pressure areas. Re-plate worn surfaces to maintain thermal performance and prevent part defects.

- Inspection: Use ultrasonic testing to detect internal defects in copper alloy inserts, which can compromise thermal conductivity. Visual checks for tarnish or corrosion ensure cooling channels remain unobstructed.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends copper alloys for clients needing rapid cooling in precision molds. We frequently use beryllium copper inserts in automotive and electronics molds, where they reduce cycle times by 25-30% for thin-walled parts. While copper alloys cost more upfront, their ability to improve part quality and production speed justifies the investment for high-volume runs. Our team uses specialized carbide tools and EDM to achieve tight tolerances in copper, ensuring inserts integrate seamlessly with steel or aluminum molds. For clients prioritizing cycle time reduction, copper alloys are a game-changing solution.

FAQs

- When should I use copper alloy inserts instead of full copper molds?

Copper alloy inserts are more cost-effective than full copper molds, targeting cooling in critical areas (e.g., thin walls) while using steel or aluminum for the rest of the mold. This balances performance and cost.

- How do copper alloys compare to aluminum in terms of mold life?

Copper alloy inserts last 50,000-100,000 cycles for non-abrasive plastics—shorter than steel but longer than aluminum in high-cooling applications. Their wear resistance improves with nickel plating.

- Are copper alloys suitable for food-grade or medical mold applications?

Beryllium copper is not recommended for direct food or medical contact due to beryllium’s toxicity. Instead, use nickel-plated chromium copper, which meets FDA and biocompatibility standards for indirect contact.