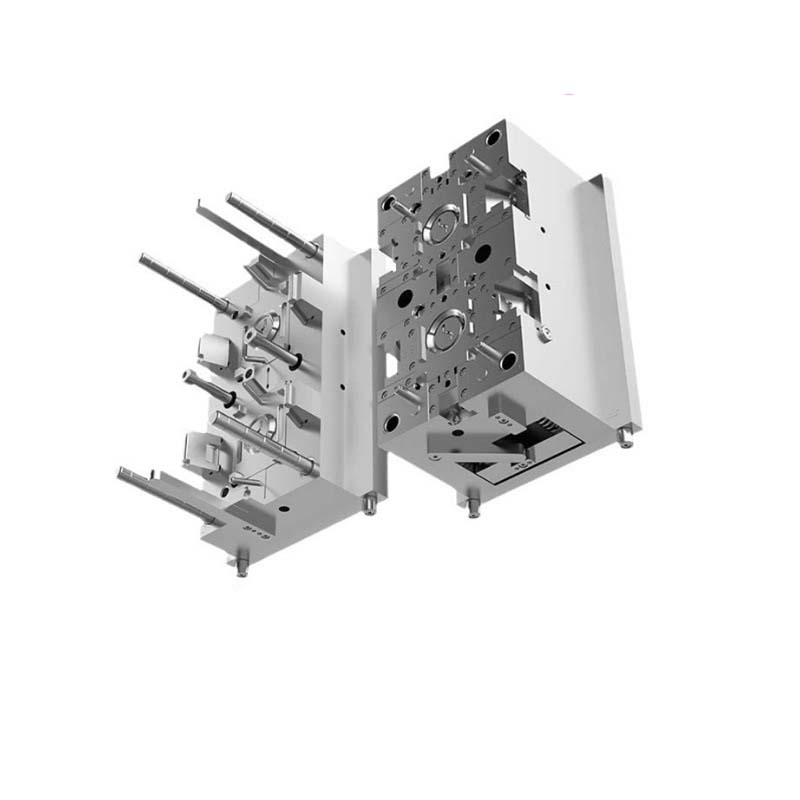

Manufacturers developing prototype molds or low-volume production tools often face a trade-off between weight, speed, and cost. Traditional metal molds are durable but heavy, expensive, and slow to machine—making them impractical for rapid prototyping or applications where portability matters. On the other hand, cheaper plastics like ABS lack the strength to withstand repeated molding cycles, leading to premature failure. This is where PMI Foam (Polymer) changes the game. As a high-performance poly(methacrylimide) foam, PMI foam combines extreme lightness with impressive strength, enabling fast, cost-effective production of lightweight molds that don’t compromise on precision. In this guide, we’ll explore how PMI foam solves the critical pain points of weight and lead time in mold making, its unique properties, and how to leverage its capabilities for rapid, reliable results.

Introduction to PMI Foam (Polymer)

PMI Foam (Polymer)—short for poly(methacrylimide) foam—is a high-performance cellular material engineered for applications demanding strength, lightness, and dimensional stability:

- Definition: PMI foam is a closed-cell rigid foam made from poly(methacrylimide), a polymer known for its excellent mechanical properties and thermal stability. Its cellular structure (with cell sizes typically 50-200 μm) gives it an ultra-low density while maintaining structural integrity.

- Standard specifications: PMI foam adheres to industry standards for high-performance foams, with strict controls on density (30-200 kg/m³), tensile strength, and compressive strength. Leading grades meet aerospace specifications (e.g., ASTM D1622 for compressive properties) to ensure consistent performance.

- Supplier brands: Key manufacturers include Evonik (Rohacell®), Diab Group (Divinycell® PMI), and 3A Composites. These brands offer PMI foam in sheets and blocks with varying densities, optimized for different load requirements in mold making.

- Industry usage: PMI foam is used in 10-15% of prototype molds and low-volume production tools, particularly in aerospace, automotive, and consumer electronics. Its ability to reduce mold weight by 70-80% compared to aluminum makes it ideal for portable tools or rapid prototyping.

- Comparison with other mold materials: PMI foam is 1/5 the weight of aluminum (30-200 kg/m³ vs. 2700 kg/m³) and 1/10 the cost of metal for prototype molds. While it’s less durable than steel (lasting 100-10,000 cycles vs. 100,000+), its speed of machining (5-10x faster than metal) and low weight make it indispensable for rapid iteration.

Properties of PMI Foam (Polymer)

The properties of PMI Foam (Polymer) make it a standout choice for lightweight, fast-turnaround molds:

- Low density (lightweight): PMI foam’s density ranges from 30-200 kg/m³, with most mold grades around 60-100 kg/m³. A 10 kg aluminum mold component can be replaced with a 1-2 kg PMI foam part, drastically reducing handling effort and enabling portable tools.

- High strength-to-weight ratio: Despite its lightness, PMI foam offers impressive mechanical properties. For example, Rohacell® 71 HF (density 70 kg/m³) has a compressive strength of 20 MPa and tensile strength of 18 MPa—sufficient to withstand low-pressure molding cycles (up to 500 psi) without deformation.

- Good thermal insulation: PMI foam has low thermal conductivity (0.03-0.05 W/m·K), making it useful for molds requiring temperature control. It insulates against heat loss, helping maintain consistent molding temperatures and reducing energy use.

- Dimensional stability: PMI foam retains its shape across temperature changes (from -50°C to 120°C) with a thermal expansion coefficient of 50-70 μm/m·°C—higher than metal but manageable for prototype applications. This stability ensures consistent part dimensions during short production runs.

- Chemical resistance: PMI foam resists most plastics, resins, and coolants used in molding, though it can be affected by strong solvents like acetone. This resistance prevents degradation during mold cleaning and use.

- Flame retardancy: Many PMI foam grades (e.g., Rohacell® FR) are flame-retardant, meeting UL94 V-0 standards. This makes them suitable for aerospace and automotive applications with strict safety requirements.

Applications of PMI Foam (Polymer) in Mold Making

PMI Foam (Polymer) excels in applications where speed, weight, and cost are critical:

- Prototype molds: For validating new designs, PMI foam molds can be machined in 1-2 days (vs. 1-2 weeks for metal), accelerating time-to-market. They’re ideal for testing form, fit, and function before investing in production tooling.

- Low-volume production molds: Runs of 10-1,000 parts (e.g., custom consumer electronics, aerospace prototypes) benefit from PMI foam’s low cost and quick turnaround. It handles thermoplastics like ABS and polyethylene with ease.

- Aerospace molds: PMI foam produces lightweight tooling for composite parts (e.g., drone frames, aircraft interior components). Its low weight reduces handling costs and makes it suitable for on-site molding.

- Automotive interior molds: Prototyping molds for dashboards, door panels, and trim use PMI foam to quickly iterate on designs, with sufficient strength to withstand low-pressure injection molding of polyurethane.

- Medical device molds: For lightweight, portable molds used in small-batch production of medical components (e.g., device housings), PMI foam’s chemical resistance and ease of machining are key advantages.

Machining and Fabrication of PMI Foam (Polymer)

Machining and fabrication of PMI foam are fast and straightforward, with minimal specialized equipment:

- Precision machining: PMI foam cuts easily with CNC routers, mills, and lasers. Carbide tools with sharp edges are recommended, with cutting speeds of 300-500 SFM—5-10x faster than aluminum machining.

- CNC milling: 3-axis CNC milling achieves tolerances of ±0.1 mm in PMI foam, sufficient for most prototypes. High-speed spindles (10,000+ RPM) produce smooth surfaces, reducing the need for post-processing.

- Cutting and shaping: PMI foam can be cut with hot wires, band saws, or waterjets for rough shaping, with CNC finishing for precision. This flexibility allows for both quick prototyping and detailed work.

- Surface finishing: Sanding with 120-400 grit paper achieves Ra 1-5 μm surface finish, suitable for most prototype molds. Sealing with epoxy or polyurethane coatings can improve surface smoothness for cosmetic parts.

- Bonding and assembly: PMI foam bonds well with epoxy adhesives, enabling the creation of large, complex molds from smaller blocks. This is critical for molds larger than standard foam sheet sizes (typically 1.2m x 2.4m).

- Machining challenges: PMI foam can generate dust during machining, requiring proper ventilation. It also has low thermal conductivity, so excessive friction can melt the surface—avoided by using sharp tools and light feeds.

Maintenance and Repair of PMI Foam (Polymer) Molds

Proper maintenance and repair extend the life of PMI foam molds, ensuring consistent performance:

- Mold cleaning: Clean PMI foam surfaces with mild soap and water or isopropyl alcohol to remove plastic residue. Avoid harsh solvents, which can dissolve the foam.

- Surface treatment: Applying a thin (0.1-0.5 mm) epoxy coating enhances wear resistance and surface smoothness, extending mold life by 2-3x. This is recommended for molds running >100 cycles.

- Repair techniques: Small cracks or dents can be repaired with epoxy putty, which bonds well to PMI foam. Sanding the repaired area ensures a smooth surface, preventing part defects.

- Preventive maintenance: Inspect PMI foam molds before each use for signs of compression or wear, especially in high-pressure areas like gates. Reinforcing these areas with fiberglass or carbon fiber patches can prevent failure.

- Inspection: Visual checks for warping or degradation are sufficient for most PMI foam molds. For high-precision applications, use calipers to verify dimensional stability, as foam can compress slightly over time.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology relies on PMI foam for rapid prototyping molds. Its 70-80% weight reduction vs. aluminum makes handling easier, while CNC machining in 1-2 days cuts prototype lead times drastically. We often use 60-100 kg/m³ density grades for low-volume runs (10-500 parts), which balance strength and cost. While PMI foam isn’t suitable for high-pressure production, it’s invaluable for validating designs before investing in metal tooling. Our team applies epoxy coatings to extend mold life, ensuring clients get reliable results at a fraction of metal mold costs. For speed and affordability, PMI foam is unmatched.

FAQs

- How many cycles can a PMI foam mold handle?

PMI foam molds last 10-1,000 cycles, depending on density and application. Low-density grades (30-60 kg/m³) work for 10-100 cycles, while high-density (100-200 kg/m³) handle 500-1,000 cycles for low-pressure molding.

- Can PMI foam molds be used with high-temperature plastics?

PMI foam withstands temperatures up to 120-150°C, making it suitable for ABS, polyethylene, and polyurethane. Avoid high-temperature plastics like PEEK (melting point >300°C), which can melt the foam.

- How does PMI foam compare to 3D-printed molds in cost and speed?

PMI foam molds are often cheaper than 3D-printed metal molds and faster to produce than 3D-printed plastic molds for large parts. They also offer better surface finish than most 3D-printed tools, reducing post-processing needs.