If you’re curious about how manufacturers create full-size parts—like airplane wings, industrial machinery components, or even entire building sections—without traditional molds or assembly lines, the answer often lies in large scale additive manufacturing (LSAM). At its core, LSAM is an advanced manufacturing process that builds three-dimensional objects layer by layer, but on a much bigger scale than standard 3D printing. Unlike desktop 3D printers that make small prototypes or household items, LSAM systems can produce parts measuring meters in size, with the strength and durability needed for industrial use. Whether you’re a factory manager exploring cost-saving production methods, an engineer designing complex components, or a business owner researching innovative manufacturing solutions, understanding LSAM is key to staying competitive in today’s industry.

Core Principles of Large Scale Additive Manufacturing

To grasp how LSAM works, it helps to start with its basic mechanics—then see how it scales up for big projects. At its heart, LSAM follows the same “layer-by-layer” logic as small-scale 3D printing, but with specialized equipment, materials, and processes to handle larger, heavier parts.

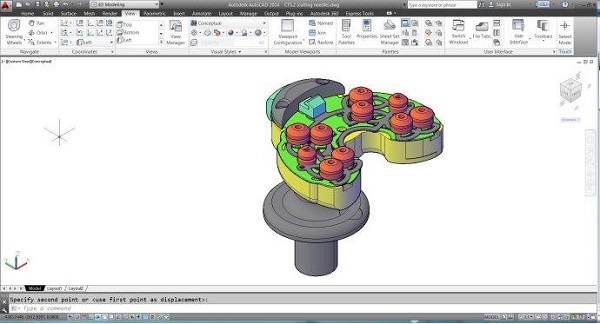

First, a digital design (usually a CAD file) is split into thin, 2D layers by software. The LSAM machine then deposits material—often in the form of molten plastic, composite filaments, or even concrete—onto a large build platform, following the design’s layers. Once one layer is set, the platform moves down (or the printer head moves up), and the next layer is added. This repeats until the full part is complete.

What makes LSAM unique is its focus on speed, material compatibility, and build volume. For example, many industrial LSAM systems use “extrusion-based” technology, where a screw inside the printer head melts thermoplastic pellets (cheaper and more durable than small-scale filaments) and pushes them through a nozzle. This allows for faster deposition—some machines can lay down 10+ pounds of material per hour—critical for large parts that might take days to print.

A real-world example of this is Cincinnati Incorporated’s Big Area Additive Manufacturing (BAAM) system, used by companies like Ford. Ford has used BAAM to print full-size automotive tooling, such as the molds for truck bumpers. Traditionally, these molds took 6–8 weeks to make and cost \(50,000–\)100,000. With BAAM, Ford cuts production time to 3–5 days and reduces costs by 70%—showing how LSAM’s core principles translate to tangible business value.

Key Technologies Powering Large Scale Additive Manufacturing

Not all LSAM systems work the same way. Different technologies are tailored to specific materials, part sizes, and industry needs. Below’s a breakdown of the most common ones, along with their strengths, use cases, and real-world applications.

| Technology | How It Works | Best For | Example Application |

| Fused Filament Fabrication (FFF) for LSAM | Melts large thermoplastic filaments (1.75–5mm thick) and deposits them layer by layer. | Low-cost, durable parts (plastics, composites). | Printing 2m-long plastic brackets for agricultural machinery. |

| Binder Jetting | Sprays a liquid binder onto a bed of metal, sand, or ceramic powder to “glue” layers together; post-processing (sintering) strengthens the part. | Metal or ceramic parts (e.g., engine components). | GE Aviation using binder jetting to make 1.5m-tall turbine housings. |

| Directed Energy Deposition (DED) | Uses a laser or electron beam to melt metal wire or powder as it’s deposited, allowing for on-the-fly adjustments. | Repairing or modifying large metal parts (e.g., ship hulls). | Naval shipyards using DED to fix cracks in 3m-wide propeller shafts. |

| Concrete Extrusion | Pushes concrete (or mortar) through a nozzle to build structural elements (walls, foundations) layer by layer. | Construction (residential, commercial buildings). | The “TECLA” house in Italy, built entirely with concrete extrusion LSAM in 2021. |

Each technology solves unique challenges. For instance, DED is ideal for repairs because it can add material to existing parts—something traditional manufacturing can’t do efficiently. Meanwhile, concrete extrusion is revolutionizing construction by cutting build times for small homes from months to weeks.

Industries Transformed by Large Scale Additive Manufacturing

LSAM isn’t just a “cool tech”—it’s reshaping how industries operate, from reducing waste to enabling designs that were once impossible. Let’s dive into the sectors where it’s making the biggest impact, with specific examples and data.

Aerospace and Defense

Aerospace is one of LSAM’s biggest adopters, thanks to its need for lightweight, high-strength parts. For example, Boeing has used LSAM to print 3m-long wing spars (the structural beams that support wings) from carbon-fiber-reinforced plastic. Traditional spars require assembling multiple pieces, which adds weight and weakens the part. LSAM creates a single, seamless spar that’s 20% lighter and 15% stronger—critical for fuel efficiency in airplanes.

Data point: The Aerospace Industries Association (AIA) reports that LSAM has reduced the time to produce aerospace components by 40–60% on average, while cutting material waste from 80% (traditional machining) to less than 5%.

Automotive

Car manufacturers use LSAM for both tooling and end-use parts. Volkswagen recently implemented an LSAM system to print full-size car chassis components. Previously, these components were made by stamping metal sheets, which required expensive dies (up to $2 million each) and long lead times. With LSAM, Volkswagen can prototype a new chassis component in 2 weeks (vs. 6 months with stamping) and produce low-volume parts without dies—saving millions in upfront costs.

Construction

The construction industry is embracing LSAM to address labor shortages and slow build times. In 2023, ICON, a U.S.-based construction tech company, used its Vulcan II LSAM system to build a 1,700-square-foot home in just 48 hours. The process uses a concrete mixture that sets quickly, and the printer can work 24/7—eliminating the need for multiple construction crews. ICON reports that LSAM-built homes cost 30% less than traditionally built ones, with 50% less material waste.

Energy

In the energy sector, LSAM is used to make large parts for wind turbines and oil rigs. Siemens Gamesa uses LSAM to print 4m-long blades for wind turbines. Traditional blades are made by hand, with a high risk of defects (up to 10% of blades are rejected). LSAM produces blades with consistent quality, reducing defects to less than 1% and extending the blade’s lifespan by 5–10 years.

Challenges and Limitations of Large Scale Additive Manufacturing

While LSAM offers huge benefits, it’s not without hurdles. Understanding these challenges is crucial for businesses considering adopting the technology—so you can plan for them and avoid costly mistakes.

High Upfront Costs

LSAM machines are expensive. A mid-range industrial LSAM system can cost \(200,000–\)1 million, and high-end models (for aerospace or construction) can exceed \(5 million. This is a barrier for small and medium-sized businesses (SMBs). For example, a small automotive parts manufacturer might struggle to justify spending \)500,000 on an LSAM machine when their current stamping equipment works—even if LSAM saves money long-term.

Material Limitations

Not all materials work well with LSAM. While plastics, carbon fiber, and concrete are common, some high-performance materials (like certain titanium alloys used in medical implants) are hard to print at scale. These materials require precise temperature control and slow deposition rates, which can make LSAM uneconomical. For instance, a medical device company might stick to traditional machining for titanium implants because LSAM can’t yet produce them with the required precision at scale.

Quality Control and Certification

Large parts printed with LSAM need to meet strict industry standards—especially in aerospace, defense, and medical fields. Ensuring every layer is uniform (no gaps or defects) is challenging. For example, a defective wing spar could cause an airplane crash, so aerospace companies require extensive testing (like X-rays or stress tests) of LSAM parts. This testing adds time and cost. The International Organization for Standardization (ISO) is still developing universal standards for LSAM, which means certification processes vary by country and industry.

Post-Processing Requirements

Many LSAM parts need post-processing to be usable. For example, a metal part printed with binder jetting might need to be “sintered” (heated in a furnace) to strengthen it, and then sanded or painted to smooth the surface. Post-processing can add 20–50% to the total production time. A construction company building an LSAM home, for example, still needs to add windows, doors, and electrical systems after the printer finishes—so the total build time is longer than just the printing phase.

How to Choose the Right Large Scale Additive Manufacturing Solution

If you’re considering LSAM for your business, the key is to match the technology to your specific needs. Here’s a step-by-step guide to help you decide:

- Define Your Goals: Start by asking: What do you want to produce? (e.g., prototypes, end-use parts, structural components) What material do you need? (e.g., plastic, metal, concrete) What’s your budget for upfront costs and ongoing maintenance?

Example: If you’re a small furniture manufacturer wanting to make custom 1m-tall chair frames from plastic, a mid-range FFF LSAM system (\(200,000–\)300,000) might be a good fit. If you’re an aerospace company making 3m-long metal turbine parts, a DED or binder jetting system ($1 million+) is necessary.

- Evaluate Material Compatibility: Check if the LSAM technology you’re considering works with your desired material. For example, if you need metal parts, avoid concrete extrusion systems. Ask vendors for sample parts made with your material to test quality.

- Assess Build Volume and Speed: Calculate the maximum size of your parts and how quickly you need to produce them. A construction company building homes needs a large build volume (5m+ in length/width), while a automotive parts maker might only need 2m. Speed matters too—if you need 100 parts per month, a slow LSAM system will cause bottlenecks.

- Consider Post-Processing Needs: Be realistic about how much post-processing you can handle. If you don’t have space for a sintering furnace, avoid binder jetting for metal parts. Look for technologies that minimize post-processing (e.g., FFF for plastics often requires less sanding than binder jetting).

- Check Vendor Support and Certification: Choose a vendor that offers training, maintenance, and help with certification. For example, if you’re in aerospace, look for vendors that work with the Federal Aviation Administration (FAA) or European Union Aviation Safety Agency (EASA) to ensure parts meet standards.

Yigu Technology’s Perspective on Large Scale Additive Manufacturing

At Yigu Technology, we see large scale additive manufacturing as a cornerstone of the next industrial revolution—especially for businesses looking to balance innovation with sustainability. What sets LSAM apart is its ability to turn “wasteful” traditional processes into efficient, circular ones: by using only the material needed for a part, LSAM cuts down on scrap, which aligns with global sustainability goals. We’ve worked with clients in automotive and construction to integrate LSAM solutions, and the biggest win we’ve seen is flexibility—small businesses can now compete with large manufacturers by producing custom parts without expensive tooling. However, we also advise clients to start small: instead of investing in a full-scale LSAM system right away, test with a smaller machine or partner with a contract manufacturer to validate ROI. As materials and certification standards improve, we believe LSAM will become as common as traditional machining—especially in industries like renewable energy and affordable housing, where it can solve pressing global challenges.

FAQ About Large Scale Additive Manufacturing

1. How is large scale additive manufacturing different from regular 3D printing?

Regular 3D printing (e.g., desktop FFF printers) is designed for small parts (usually under 30cm) and prototypes, using thin filaments or small amounts of resin. LSAM, by contrast, handles parts measuring meters in size, uses larger amounts of durable materials (e.g., industrial-grade plastics, metal wire), and is built for high-volume or industrial use. LSAM also requires more powerful hardware and specialized software to manage large build volumes.

2. Is large scale additive manufacturing cost-effective for small businesses?

It depends on your use case. For SMBs that need custom parts, low-volume production, or fast prototyping, LSAM can be cost-effective—especially if it replaces expensive tooling (e.g., stamping dies). However, the high upfront cost of LSAM machines ($200,000+) can be a barrier. Many SMBs start by partnering with contract manufacturers (who own LSAM machines) to test projects before investing in their own equipment.

3. What’s the maximum size of a part that can be made with LSAM?

The maximum size varies by technology and machine. For example:

- Concrete extrusion LSAM systems (like ICON’s Vulcan II) can build parts up to 10m long.

- Aerospace-focused DED systems (like GE’s Concept Laser) can handle parts up to 5m in diameter.

- Some industrial FFF systems (like Cincinnati’s BAAM) can print parts up to 3m x 1.5m x 1.5m.

4. Are LSAM parts as strong as traditionally made parts?

Yes—often stronger. For example, LSAM-made carbon-fiber parts are often stronger than traditionally assembled parts because they have no seams (which are weak points). Metal parts made with DED or binder jetting can match or exceed the strength of machined metal, especially when post-processed (e.g., sintered). Industries like aerospace and defense only use LSAM parts after rigorous testing to confirm strength and durability.

5. What’s the future of large scale additive manufacturing?

The future will focus on three areas:

- Cheaper machines: As technology scales, LSAM machines will become more affordable for SMBs.

- New materials: Researchers are developing LSAM-compatible materials like biodegradable plastics and high-performance ceramics.

- Faster printing: Improvements in deposition rates (e.g., faster laser melting for metal) will reduce production time for large parts.

- Integration with AI: AI will help optimize LSAM designs (reducing material use) and monitor prints in real-time (catching defects early).