Introduction: Why are machining experts the "invisible cornerstone" of modern industry?

Behind the precision parts of aerospace, the core transmission system of automobiles, and the implanted devices of medical devices, machining specialists are inseparable (machining experts). With the transformation of the manufacturing industry to "precision, customization, and intelligence", these professionals who master core processing technologies are not only equipment operators, but also decision-makers of process optimization and designers of industry solutions. This article will comprehensively dismantle the core values of machining experts from core skills, industry applications, growth paths to quality control, and help you clarify the key logic of "becoming an expert" or "choosing expert cooperation".

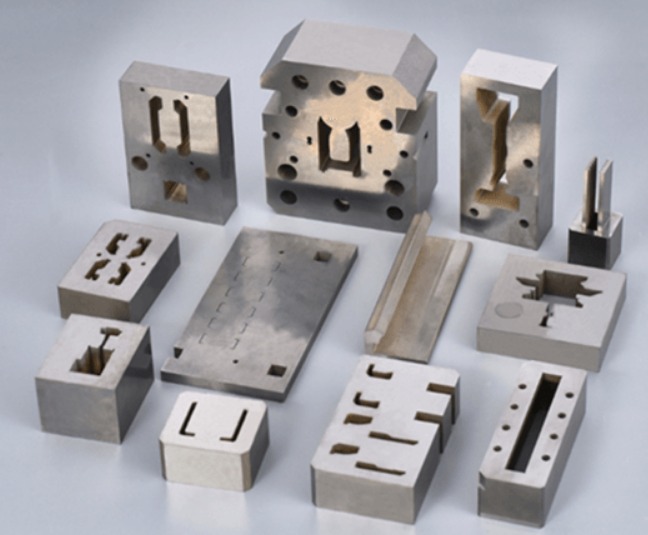

1. The core technology of machining experts: "hard power" from operation to precision

To become a machining expert, you must first master the core technology throughout the whole processing process, which is not only the ability to operate the equipment, but also the ultimate pursuit of "precision" and "efficiency".

1. Core processing technology and equipment operation

The technical system of machining experts is based on CNC machining, covering milling and turning (milling and turning), and multi-axis machining(multi-axis machining) and other key processes. Taking 5-axis linkage machining as an example, it can realize the one-time forming of complex curved parts, which is the core processing method of aero engine blades, precision molds and other products - data from an aviation manufacturing company shows that after using 5-axis machining, the blade processing cycle is shortened by 40%, and the scrap rate is reduced from 3% to 0.8%.

At the same time, experts need to be proficient in operating various machining tools and equipment, including vertical machining centers, horizontal lathes, electrical discharge machining machines (EDM), etc., and be able to select suitable tools and cutting parameters according to material characteristics (such as titanium alloys, superalloys). For example, when machining titanium alloy parts for medical devices, diamond-coated tools should be used with a low-speed and high-feed cutting strategy to avoid material deformation.

2. Programming and precision control capabilities

CAD/CAM programming is the "brain" of machining, and experts need to be proficient in using software such as Mastercam and UG NX to convert 3D models into machining code and optimize the path through simulation to avoid interference. A case study from an automotive parts company showed that CAM software reduced machining time and tool losses by 25% and tool losses for complex transmission housings through path optimization.

Tolerance and surface finish control is key to demonstrating expert level. Industrial-grade parts often have tolerances of ±0.005mm (equivalent to 1/14 of the diameter of a hair) and surface roughness of Ra0.8μm or less, which requires experts to not only accurately debug the equipment but also deal with environmental disturbances during the processing process through temperature compensation, vibration suppression, and other means. For example, in precision tooling, part tolerances can be controlled within ±0.002mm by using a constant temperature workshop (temperature fluctuation ±0.5°C) and a hydraulic vibration damping table.

2. Industry application scenarios: "customized solutions" by machining experts

The value of machining experts is ultimately reflected in the practical applications of different industries, where they need to provide full-process solutions from prototype to mass production based on industry characteristics.

| Industry Sectors | Core requirements | Expert solutions | Use Cases: |

| aerospace machining | High temperature resistance, high-strength material processing, ultra-high precision requirements | It adopts 5-axis linkage machining + vacuum heat treatment process to strictly control the residual stress of the parts | The engine turbine disc machining of an aviation enterprise has a tolerance of ±0.003mm and a surface roughness of Ra0.4μm |

| Automotive Parts Machining | High mass production efficiency, cost control | Design special fixtures to achieve multi-station processing, and introduce automatic loading and unloading system | The transmission gear processing of a car company increased the production capacity to 500 pieces in a single shift, with a defect rate of 0.5% |

| Medical Device Machining | Biocompatible material processing, aseptic production | Cutting fluid-free machining (MQL technology) is used, and the parts are electropolished | Artificial joint prosthesis processing with surface roughness Ra0.2μm meets ISO 13485 medical standards |

| Prototype machining | Rapid prototyping and flexible adjustment | Combine 3D printing + CNC finishing to shorten the R&D cycle | A technology company's drone fuselage prototype took just 72 hours from design to sample delivery |

In addition, for custom machining solutions, experts need to have an interdisciplinary mindset. For example, a new energy company needs to customize a special-shaped battery shell, and experts not only need to design the processing process, but also need to work with material engineers to optimize the aluminum alloy formula to ensure that the shell is both lightweight and impact resistant, and finally meet the customer's special installation needs through the "stretch molding + CNC finishing" solution.

For high-volume production machining, experts need to focus on efficiency and cost balance, optimizing production layout and reducing changeover time through lean manufacturing in machining. A case study from an electronic component factory showed that after experts reconstructed the processing process, the production line changeover time was reduced from 45 minutes to 15 minutes, the production capacity was increased by 30%, and the processing cost per product was reduced by 18%.

3. The road to advancement: How to become a senior machining expert?

Becoming a machining expert is not achieved overnight, it requires systematic knowledge accumulation, practical polishing and continuous learning, the following is a clear growth path:

1. Knowledge system and training foundation

First of all, it is necessary to build a solid theoretical foundation, including mechanical drawing, material mechanics, GD&T (Geometric Dimensioning and Tolerancing) (geometric tolerance annotation) and other core knowledge - GD&t, as an internationally accepted tolerance annotation language, is the key to communication between experts and design and quality inspection departments, and mastering its principles can avoid 90% of production misunderstandings.

In terms of training paths, you can get started through vocational training in machining or machining technology education, such as obtaining NIMS (National Manufacturing Skills Standards) certification in the United States, EMC in Europe, etc Machining certifications, which are an important reflection of industry recognition.

2. Practice accumulation and continuous advancement

Machining is a "hands-on" skill that requires starting in a basic position (such as a CNC operator) and gaining experience in machining different materials and processes. It is recommended to focus on a certain subdivision (such as precision mold processing, medical parts processing) in the early stage, and cultivate for 3-5 years to form a professional advantage - the growth experience of a senior expert shows that after focusing on aerospace parts processing for 10 years, his technical reputation in the field of titanium alloy and superalloy processing has made it a "scarce resource" in the industry.

At the same time, it is necessary to maintain the learning of advanced machining techniques, such as the combination of additive manufacturing (3D printing) and subtractive processing, and the application of digital twin technology in processing. In recent years, AI-driven intelligent machining systems have become increasingly popular, and experts need to master data analysis capabilities to monitor machining data in real time and predict potential problems through SPC (Statistical Process Control) in machining (statistical process control) tools.

3. Career development direction

The career path of machining experts is clear, which can be divided into technical deep cultivation and management:

- Technical: CNC Operator→ Process Engineer→ Senior Machining Specialist→ Technical Director (focus on process optimization, technological innovation)

- Management: CNC operator→ production supervisor→ shop manager→ operations director (focus on production management, team coordination)

- Entrepreneurial: Establish customized processing enterprises with technology accumulation to serve customers in subdivided industries

4. Quality Control and Optimization: The "Lean Way" of Machining Experts

In the fierce market competition, the balance of quality, efficiency and cost is the core competitiveness of enterprises, which is also the core value of machining experts.

1. Whole process quality control method

Machining Quality Control runs through the entire process from raw material to finished product:

- Incoming material inspection: Detect the composition of the material through a spectrum analyzer to ensure compliance with design requirements (e.g., Ti-6Al-4V titanium alloy commonly used in aviation parts, aluminum and vanadium content need to be verified)

- Process testing: Inspection and measurement equipment such as coordinate measuring instruments and laser interferometers are used to monitor key dimensions in real time to avoid batch scrapping

- Finished product inspection: Combined with non-destructive testing (such as ultrasonic testing, X-ray testing) to investigate internal defects and ensure product reliability

The case of a medical device company showed that by establishing a three-level quality inspection system of "incoming materials-process-finished products", the pass rate of its orthopedic implants increased from 98.5% to 99.9%, and the customer complaint rate decreased by 80%.

2. Efficiency and cost optimization strategies

Machining process optimization is key to improving efficiency and reducing costs, and experts often use methods such as:

- Tool optimization: Choose high-performance tools such as coated tools and diamond tools to extend service life (e.g., TiAlN coated tools for 2-3 times longer tool life when milling steel parts)

- Optimization of cutting parameters: Optimal cutting speed, feed rate, and depth of cut are determined by orthogonal testing (e.g., from 100m/min to 150m/min for 50% increase in machining efficiency) when machining 45-gauge steel.

- Automation upgrade: Introduce robot loading and unloading and AGV logistics systems to reduce manual intervention (after the automation transformation of a mechanical processing plant, the per capita production capacity increased by 60% and the labor cost was reduced by 40%)

In addition, machining cost reduction can be achieved through material utilization optimization, such as nesting techniques to nest multiple parts on raw materials, increasing material utilization from 60% to more than 85% and reducing single-batch processing costs by 25%.

5. Yigu Technology's view

As a technology enterprise deeply involved in the field of high-end manufacturing, Yigu Technology believes that the core competitiveness of machining experts has shifted from "operational proficiency" to "technology integration ability". In the context of Industry 4.0, experts must not only be proficient in traditional machining processes, but also need to integrate cross-disciplinary knowledge such as CAD/CAM programming, data analysis, and automation technology to become "compound technical talents". In the future, with the popularization of AI, digital twins and other technologies, machining will transform to "intelligent and unmanned", but the experience and judgment of experts and process innovation ability are still irreplaceable cores - only by deeply combining technical tools with practical experience can we truly empower high-end manufacturing and promote the development of the industry in the direction of higher precision, higher efficiency and lower cost.

6. FAQ

- What software does a machining specialist need to master?

Core requirements: CAD software (SolidWorks, AutoCAD), CAM software (Mastercam, UG NX); Advanced recommendations: SPC statistical software (Minitab), simulation software (ANSYS).

- What is the core difference between multi-axis machining and regular CNC machining?

Multi-axis machining (such as 5-axis) can realize multi-sided one-time forming of parts, reduce the number of clamping, improve accuracy and efficiency, and are suitable for complex curved parts; Ordinary CNC machining (3-axis) is suitable for simple structural parts, with lower costs and lower barriers to operation.

- How long does it take to become a machining expert?

Basic entry (being able to operate equipment independently) takes 1-2 years; It takes 3-5 years to master core technologies (programming, precision control); It takes 5-10 years of practice to become an expert in a subdivision (e.g., aviation, medical).

- What are the common quality issues in machining? How to solve it?

Common problems: dimensional deviation, surface roughness not up to standard, part deformation. Solution: Optimize cutting parameters, adopt a constant temperature machining environment, increase stress relief heat treatment processes, and select appropriate tools and fixtures.

- What are the development trends of high-end machining?

Core trends: intelligence (AI-driven process optimization), green (cutting fluid-free processing, energy-saving equipment), compounding (additive + subtractive hybrid processing), customization (low-batch high-precision production).