In the field of modern machining, the proportion of plastic for machining continues to rise, gradually becoming an important alternative to metal materials. This is inseparable from the multiple core advantages of plastics themselves, which can not only improve processing efficiency, reduce production costs, but also expand product application scenarios. This article will systematically sort out the eight advantages of using plastic for machining, combine real cases and data comparisons, deeply analyze the practical value of each advantage, and give suggestions for plastic selection in different scenarios.

1. Introduction

With the transformation of the manufacturing industry to precision, lightweight, and green, plastic for machining has achieved a wide range of applications in various industries such as electronics, automotive, medical, and chemical industries due to its unique performance advantages. According to industry statistics, the global machining plastics market size will exceed US$90 billion in 2024, a year-on-year increase of 8.5%, with the growth rate of engineering plastics and specialty plastics particularly significant. Compared with traditional metal processing, plastic processing has shown obvious advantages in cost control, performance adaptation, environmental protection, etc., and has become an important force in promoting the transformation and upgrading of the manufacturing industry. The following will break down the eight core advantages of machining with plastics in detail.

2. Diversity of plastics

2.1 Different types of plastics and their properties

There are many types of plastic materials, and different types of plastics have differentiated characteristics to meet diverse processing needs. Common plastic for machining is mainly divided into three categories: general plastics, engineering plastics and special plastics: general plastics (such as PP, PS, PVC) are low cost, simple to process, and have basic mechanical properties; Engineering plastics (such as POM, PC, PA) have high mechanical strength and good dimensional stability, suitable for precision machining scenarios; Specialty plastics (such as PTFE and PEEK) have extreme properties such as high temperature resistance and strong corrosion resistance, and are suitable for high-end manufacturing applications. The following table clearly shows the core characteristics of a typical plastic:

| Plastic type | Core features | Applicable scenario keywords |

| Polypropylene (PP) | Chemical resistance, light weight, good toughness | Chemical, automotive, food |

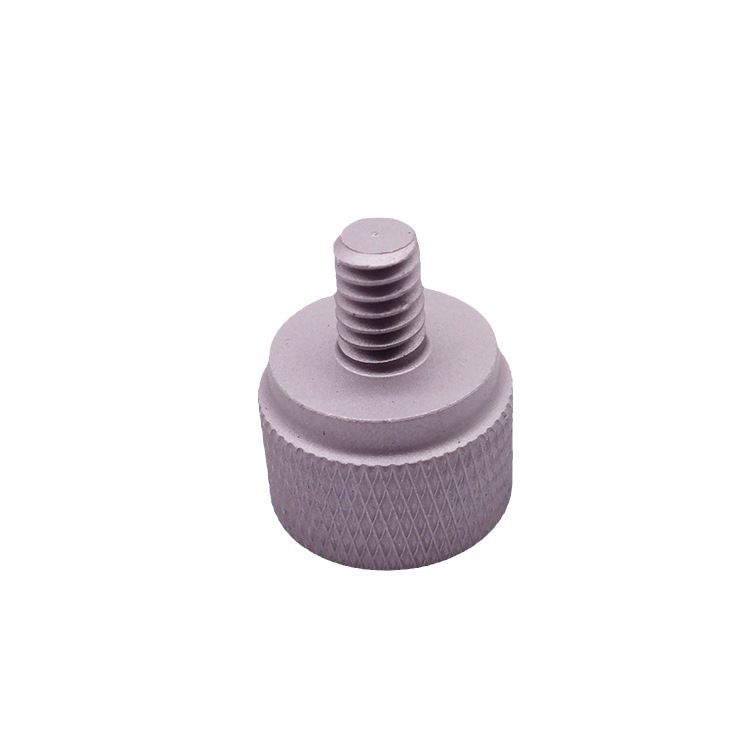

| Polyoxymethylene (POM) | Excellent wear resistance, dimensional stability, and high strength | Precision transmission, mechanical parts |

| Polycarbonate (PC) | Impact resistance, high light transmission, high temperature resistance | Electronic enclosures, medical protection |

| Polytetrafluoroethylene (PTFE) | Corrosion resistant, self-lubricating, extreme temperature resistance | high-end chemical industry, aerospace |

2.2 Plastic Selection for Different Applications

The diversity of plastics allows them to be precisely matched to different processing application needs. For example, in the corrosive environment of the chemical industry, PP or PTFE with excellent chemical resistance can be chosen; In the precision transmission scenario of the electronics industry, POM's wear resistance and dimensional stability make it the first choice; In the transparent protection scenario of the medical industry, the high light transmission and impact resistance of PC are more advantageous. According to the needs of different parts, a precision electronics factory selected POM processing transmission gears, PC shells, and PP production terminals, which achieved the optimal balance between product performance and cost, and the product qualification rate increased to 99.3%.

3. Lightweight advantage

3.1 Comparison of the density of plastics with metals

Lightweight is one of the core advantages of Plastic for Machining, and the key is the low density nature of plastics. The density of common plastics is mostly between 0.9-1.5g/cm³, while the density of metal materials (such as steel and aluminum) is 7.8g/cm³ and 2.7g/cm³ respectively. Data comparison shows that the weight of parts of the same volume can be reduced by more than 80% by replacing steel with plastic; Replace aluminum processing with 40%-60% weight reduction. For example, an auto parts manufacturer used PP machined bumpers, and compared with traditional steel bumpers, the weight was reduced from 8kg to 2.5kg, and the weight reduction effect was significant.

3.2 The impact of lightweight on transportation and operation

Lightweight not only reduces the weight of the product itself, but also brings chain advantages in transportation and operation. In terms of transportation, lightweight parts can increase the single transportation volume and reduce transportation energy consumption and costs: after a home appliance company replaced the metal shell with a plastic shell, the transportation volume of a single batch of products increased by 35% and the transportation cost was reduced by 22%. In terms of operation, lightweight parts are more convenient for manual installation and equipment operation, reducing operational fatigue and equipment load: in the field of medical devices, lightweight plastic surgical instruments increase the operating efficiency of medical staff by 20% and reduce the wear rate of equipment by 15% compared with metal instruments.

4. Cost-effectiveness

4.1 Analysis of plastic production costs

plastic for machining has significant advantages in production costs, mainly reflected in raw material costs and processing costs. In terms of raw materials, the unit price of general plastics (such as PP and PS) is only 1/3-1/2 of steel. In terms of processing cost, the energy consumption of plastic processing is only 1/5-1/3 of that of metal processing, and the processing process is simple, with high cutting and forming efficiency and low scrap rate. According to data from a small machinery factory, the production cost per unit product is reduced by 45% compared with steel pipes processed with PP.

4.2 Economic advantages in long-term use

Plastics can also show sustained economic advantages in long-term use. On the one hand, the corrosion resistance and wear resistance of plastics can extend the service life of products and reduce replacement and maintenance costs: a chemical company uses PTFE to process reactor seals, which have a service life of up to 10 years, while traditional metal seals need to be replaced 1-2 times a year, reducing long-term maintenance costs by more than 80%. On the other hand, the lightweight of plastics can reduce the energy consumption of equipment operation, especially in the field of transportation, every 10% increase in vehicle lightweight can increase fuel efficiency by 5%-8%, and long-term use can save a lot of fuel costs.

5. Corrosion resistance

5.1 Plastics in harsh environments

Most plastics have excellent corrosion resistance and can work stably in harsh environments such as acids and alkalis, oils, and solvents, which is an incomparable advantage of metal materials. For example, PP can withstand most strong acids and alkalis, such as hydrochloric acid and sulfuric acid; PTFE can resist strong corrosive substances such as aqua regia and hydrofluoric acid, and can still work normally in a high-temperature corrosion environment of 260°C; PVC has good oil and solvent resistance. A coastal chemical enterprise used PP processing pipelines in an environment with high humidity and high salt spray, and there was no corrosion and leakage for 5 years, while traditional metal pipes only showed obvious corrosion after 1 year of use.

5.2 Comparison of corrosion resistance with metal materials

Metal materials (such as steel, iron, copper) are prone to oxidation and rust in humid and acid-alkali environments, leading to performance degradation or even failure, requiring additional anti-corrosion treatments (such as electroplating and spraying), which increases costs and processes. Plastics can be used directly in harsh environments without additional anti-corrosion treatment. Data comparison shows that in the same acid-alkali environment, the service life of plastic parts is 5-10 times that of metal parts without anti-corrosion treatment, and 2-3 times that of metal parts that have been treated with anti-corrosion treatment. In the petrochemical industry, replacing metal processing storage tanks and pipelines with plastics can save a lot of anti-corrosion treatment costs and later maintenance costs.

6. Processing flexibility

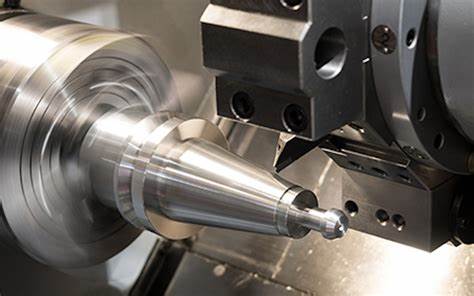

6.1 Processing methods and technologies of plastics

Plastic for Machining offers high processing flexibility and can be adapted to a variety of processing methods, including cutting, milling, drilling, injection molding, laser cutting, 3D printing, etc. Different processing methods can meet different production needs: in mass production, injection molding can achieve efficient molding; In precision machining, CNC cutting can ensure machining accuracy; For customized production, 3D printing can quickly realize the formation of complex structures. Plastics have lower processing temperature and pressure requirements, and the input cost of processing equipment is lower than that of metal processing equipment, making it especially suitable for small and medium-sized enterprises.

6.2 Customization and Implementation of Complex Shapes

Plastics are highly plastic, allowing for easy processing and customized production of complex shapes, which is an advantage that is difficult for metal processing to achieve. For example, in the electronics industry, plastics can be processed into shell parts with complex grooves and snaps, without subsequent assembly, and can be molded in one go; In the medical industry, plastic implantable parts can be customized according to patient needs, with a higher degree of adaptability. A medical device company uses 3D printing technology to process customized plastic orthopedic implants, which not only has high molding accuracy, but also shortens the production cycle, from the traditional 7 days to 24 hours, and the patient adaptation satisfaction is increased by 90%.

7. Insulation performance

7.1 Electrical insulation characteristics of plastics

The vast majority of plastics are excellent electrical insulators, with high breakdown voltage and large insulation resistance, which can effectively block current conduction and ensure the safety of electrical equipment. The breakdown voltage of common plastics is more than 10kV/mm, which is much higher than that of metal materials (metal is the conductor, and the breakdown voltage is close to 0). In addition, the insulation performance of plastics is less affected by temperature and humidity, and can maintain a stable insulation effect in different environments, making it suitable for core insulation components of electrical equipment.

7.2 Advantages in Electronic and Electrical Applications

The insulating properties of plastics make them indispensable in the electronics and electrical industry. For example, in electronic devices, plastics are used to make circuit board bases, terminal blocks, shells and other components, which can effectively avoid short circuits; In the power industry, plastics such as PVC and PE are used to make insulation layers for wires and cables to ensure the safety of power transmission. In the field of new energy, plastics are used to make battery shells and insulation accessories to improve the safety and stability of batteries. An electronic equipment manufacturer uses PCs to make circuit board shells, which not only have good insulation, but also have impact resistance, and reduce the product failure rate by 60%.

8. Environmental protection and sustainability

8.1 Use of recyclable plastics

With the improvement of environmental awareness, recyclable plastics are becoming more and more widely used in plastic for machining. Common recyclable plastics include PP, PE, PET, PVC, etc., which can be reprocessed into new plastic products after recycling to achieve resource recycling. According to industry data, the global utilization rate of recyclable machined plastics will reach 42% in 2024, an increase of 15 percentage points from 2020. A packaging company uses recycled PP to process packaging pallets, which not only reduces the cost of raw materials, but also reduces the generation of plastic waste, and wins both environmental benefits and economic benefits.

8.2 The role of plastics in sustainable development

Plastics play an important role in driving sustainable development in manufacturing. On the one hand, the lightweight of plastics can reduce energy consumption and carbon emissions throughout the life cycle of products: for every 10% increase in vehicle lightweight, the carbon emissions of the whole life cycle can be reduced by 6%-8%. On the other hand, the research and development and application of biodegradable plastics (such as PLA and PHA) have further solved the problem of plastic waste pollution. This type of plastic can degrade quickly in the natural environment and does not cause long-term harm to the environment, and has been applied in medical, food packaging and other fields, providing new solutions for sustainable development.

9. Industry application examples

9.1 Application cases of plastics in different industries

- Automotive industry: PP is used to process bumpers and interior panels, and PA is used to process engine transmission parts to achieve vehicle lightweight and performance improvement.

- Electronics industry: use PC to make mobile phones and computer shells, use POM to process keyboard buttons, and use PVC to make wire insulation layers to ensure product insulation and accuracy;

- Medical industry: use PC to process surgical instrument shields, use PTFE to make artificial blood vessels, and use degradable PLA to process disposable medical consumables;

- Chemical industry: PP and PTFE are used to process storage tanks, pipes, and seals to resist corrosive environments.

9.2 Analysis of successful cases

In order to improve the battery life of the vehicle, a new energy vehicle manufacturer uses plastic for machining instead of metal materials on a large scale: PP is used to process body interior parts, PC is used to make battery shells, and PA is used to process transmission gears. Through a comprehensive lightweight transformation, the curb weight of the vehicle has been reduced by 120kg and the cruising range has been increased by 15%. At the same time, the processing cost of plastic parts is reduced by 30% compared with metal parts, and the production efficiency is increased by 40%. In addition, the interior parts made of recyclable plastic can be recycled and reused after scrapping, which further improves the environmental protection of the product and has been widely recognized by the market, with annual sales of the model exceeding 200,000 units.

10. Conclusion

The use of plastic for machining has eight core advantages: the diversity of plastics can be adapted to different application needs, lightweight can reduce transportation and operating costs, cost-effectiveness throughout the entire production and use cycle, corrosion resistance is suitable for harsh environments, processing flexibility is easy to achieve customization and complex molding, excellent insulation performance ensures electrical safety, and environmental sustainability is in line with the trend of green development. These advantages make it widely used in multiple industries and become an important material to promote the transformation and upgrading of the manufacturing industry. In the processing process, enterprises should combine their own product needs, make full use of the advantages of plastics, choose appropriate plastic types and processing processes, and achieve the optimal balance of product performance, cost and environmental protection.

Yigu Technology Perspective

Yigu Technology believes that the core of the advantages of plastic for machining lies in the dual empowerment of "performance adaptability" and "sustainability". In the future, with the development of material technology, modified plastics and biodegradable plastics will become the mainstream direction. Enterprises should actively embrace new plastic materials, combine advanced processing technology, and fully tap the advantages and value of plastics. At the same time, the establishment of a plastic recycling system and the promotion of green development of plastic processing can enhance product competitiveness while practicing the concept of sustainable development and achieving long-term progress in the industry.

FAQ

1. Which plastic for machining is more suitable for processing in a high-temperature environment? Preferential selection of special plastics with excellent high-temperature resistance, such as PTFE (service temperature -200°C to 260°C), PEEK (thermal deformation temperature 260°C); If the cost is limited, you can choose PC (heat deflection temperature 130°C) and POM (heat deflection temperature 110°C) in engineering plastics, which can meet most medium and high temperature processing needs.

2. Can recyclable plastic processing affect product performance? After standardized processing, high-quality recycled plastics can be close to new materials without significantly affecting product performance. However, it should be noted that the performance of recycled plastics will decrease slightly with the increase of the number of recycles, which is suitable for processing general parts with low performance requirements. New materials are recommended for high-precision, high-demand parts.

3. Can the insulation properties of plastic processing meet the needs of high-voltage electrical equipment? OK. Choose special plastics for high-voltage insulation (such as epoxy resin, PTFE), whose breakdown voltage can reach more than 20kV/mm, which can meet the insulation needs of high-voltage electrical equipment. In practical applications, it is necessary to select plastics with corresponding insulation properties according to the voltage level of the equipment, and control the processing accuracy.

4. How to ensure the mechanical strength of parts by replacing metal processing with plastic? Preferential selection of engineering plastics with high mechanical strength (such as PA, POM, PC), whose tensile strength, hardness and other properties can be close to some metals; If the strength requirements are high, modified plastics (such as glass fiber reinforced PA) can be used to further improve the mechanical strength. At the same time, optimize the structural design of parts to make up for the lack of plastic strength by increasing wall thickness and stiffeners.