For startups, engineers, and established companies launching new products, the traditional injection molding model presents a major hurdle: the high cost of steel production tooling for volumes you don't yet need. Small batch injection molding is the strategic solution, enabling the production of custom plastic parts in quantities from 50 to 10,000 units at a feasible cost. This guide demystifies the processes, technologies, and economics of low-volume molding, providing a clear roadmap for innovators who need functional, high-quality prototypes, bridge-to-production parts, or limited market runs without the financial burden of mass-production tooling.

What Is Small Batch Injection Molding?

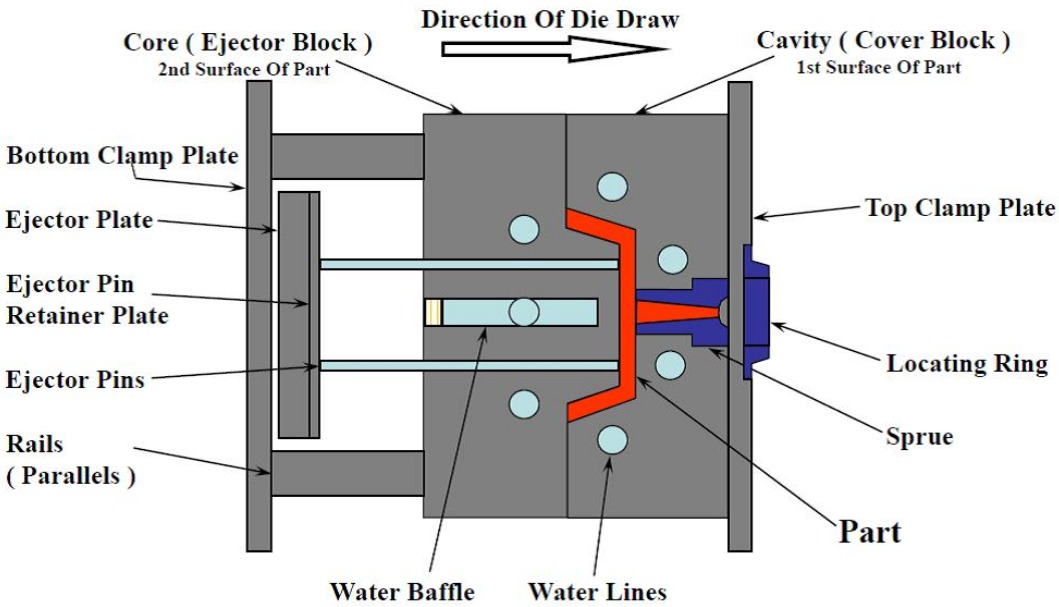

Small batch injection molding is a specialized manufacturing approach focused on producing low to medium volumes of plastic injection molded parts. It bridges the gap between one-off prototyping (like 3D printing or CNC machining) and full-scale mass production. The core innovation lies not in the injection molding machine itself, but in the tooling strategies employed to drastically reduce the upfront mold cost and lead time. This makes the entire process viable for product validation, market testing, and initial product launches, providing parts with true production-grade materials, finishes, and mechanical properties.

Why Choose Small Batches Over Mass Production?

The decision to use small batch injection molding is driven by risk management, cash flow, and strategic agility, not just low volume.

- Validate Design and Market Fit: Before investing $50,000+ in a steel production mold, you can produce 500-5,000 units with a low-cost tool to test function, gather user feedback, and confirm market demand. This de-risks the entire product launch.

- Manage Cash Flow and Inventory: For bootstrapped startups or companies with seasonal products, committing to a massive production order is financially dangerous. Small batch production allows you to manufacture what you need, when you need it, minimizing capital tied up in inventory.

- Accelerate Time-to-Market: Aluminum or soft-steel molds can be machined in 2-4 weeks, compared to 8-16 weeks for hardened steel. This lets you get functional parts into the market or the hands of beta testers months sooner.

- Support Agile Development: Design iterations are inevitable. Modifying or even replacing a low-cost prototype mold is financially tolerable, whereas changing a production steel mold is a costly and time-consuming setback.

How Low Can Volume Go—Minimum Order Quantities Explained

The minimum order quantity (MOQ) in small batch molding is directly tied to the tooling amortization strategy. Unlike mass production, where MOQs are in the tens of thousands, small batch MOQs are far more accessible.

- Typical Volume Ranges:

- Ultra-Low Volume (50 - 500 parts): Ideal for functional prototypes, pre-clinical testing, or niche replacement parts. Often served by rapid tooling methods.

- Standard Low Volume (500 - 5,000 parts): The sweet spot for bridge production, initial market launches, and specialized industrial components. Served by aluminum and mild steel tooling.

- Medium Volume (5,000 - 25,000 parts): For established products with steady but not massive demand. May use pre-production steel molds.

- The MOQ Logic: The quoted MOQ is the quantity at which the per-part price makes sense, given the fixed tooling cost. For example, a $5,000 aluminum mold for a complex part might have an MOQ of 500 units to sensibly amortize the tooling ($10/part for tooling alone). A simpler $1,500 mold might have an MOQ of 100.

Which Mold Technologies Reduce Up-Front Cost?

The breakthrough in small batch injection molding is the use of alternative, cost-effective mold materials and construction methods.

| Technology | Description | Best For | Key Advantage |

|---|---|---|---|

| Rapid Aluminum Tooling | CNC-machined from 7075 or 6061 aluminum plate. | 50 - 5,000 parts. Excellent for complex geometries and good surface finishes. | Fastest turnaround (2-4 weeks), good thermal conductivity for faster cycles. |

| Mild Steel (P20, 4140) Tooling | Machined from pre-hardened steel, but not through-hardened. | 5,000 - 50,000+ parts. When more durability is needed than aluminum offers. | Longer lifespan than aluminum, can be surface hardened for critical areas. |

| Insert Molds / Master Unit Dies | Uses a standard mold frame with interchangeable cavity inserts. | Families of similar parts or frequent design changes. | Only the custom inserts need to be machined for new parts, saving cost and time. |

| 3D-Printed Mold Inserts | Cavities are 3D printed in metal (DMLS/SLM). | Extremely complex conformal cooling or geometries impossible to machine. Allows for <100 parts. | Unmatched design freedom for internal cooling channels to reduce cycle time. |

Aluminum vs. Soft-Steel Tooling: What Fits Your Needs?

Choosing between aluminum and mild (soft) steel is the central economic and technical decision.

| Factor | Aluminum Mold (e.g., 7075-T6) | Mild Steel Mold (e.g., P20 Pre-Hardened) |

|---|---|---|

| Tooling Cost | Lowest. Typically 60-80% less than a production hardened steel mold. | Moderate. 40-60% less than hardened steel, but 50-100% more than aluminum. |

| Tooling Lead Time | Fastest. 2-4 weeks. | Moderate. 4-7 weeks. |

| Mold Lifespan | 10,000 - 50,000 shots. Suitable for most plastics; abrasive materials (glass-filled) will wear it faster. | 50,000 - 100,000+ shots. More resistant to wear and abrasion. |

| Surface Finish | Can achieve SPI A-2 (fine polish) but may not hold high polish as long as steel. | Can achieve and maintain excellent polish and texture replication. |

| Thermal Conductivity | Excellent. Cools parts faster, reducing cycle time by 15-30%. | Good, but lower than aluminum. |

| Best Application | Prototypes, market tests, bridge production where speed and low upfront cost are critical. | Extended low-volume runs, pre-production, or parts with abrasive fillers where mold longevity is needed. |

Professional Insight: A common misconception is that aluminum molds are "low quality." For the right application, they are the optimal tool. For a startup launching a consumer electronics enclosure in ABS, an aluminum mold producing 3,000 units is perfect. It provides production-quality parts for crowdfunding fulfillment and initial sales. If demand skyrockets, the revenue generated can fund a hardened steel production mold, making the aluminum tool a perfect risk-free stepping stone.

How Fast Can You Get Parts—Typical Lead Times?

Speed is a primary advantage of small batch injection molding. The timeline is compressed at the tooling stage.

- From Approved Design to First Samples:

- Aluminum Mold: 3-5 weeks (2-4 weeks for tool machining, 1 week for sampling and tuning).

- Mild Steel Mold: 5-8 weeks.

- Production Run Time: Once the mold is sampled and approved, production of the batch itself is very fast. Producing 1,000 parts might take only 2-5 days of press time, depending on part size and cycle time.

- Total Project Lead Time: For a typical order of 1,000 parts, expect a total turnaround of 4-7 weeks from order to shipped goods, inclusive of tooling.

How to Control Per-Part Cost at Low Volumes?

The total cost comprises fixed costs (tooling) and variable costs (materials, machine time). The strategy is to minimize the impact of fixed costs.

- Optimize Part Design for Manufacturability (DFM): This is the single most impactful factor. Simplify geometry, ensure uniform wall thickness, add draft, and avoid undercuts that require complex mold actions. A simpler part means a simpler, cheaper mold and faster cycle times.

- Choose the Right Material: Standard, easy-to-process materials like ABS, Polypropylene, or Nylon 6 are far more economical than exotic, high-temperature, or low-flow plastics. They process faster and with fewer defects.

- Select the Optimal Mold Technology: Match the tooling to your true volume needs. Don't over-invest in a steel mold for 500 parts.

- Minimize Secondary Operations: Design parts that don't require painting, ultrasonic welding, or complex assembly out of the mold. A clean, functional part straight from the press keeps costs down.

Cost Example Breakdown:

- Part: Small enclosure (100g in ABS).

- Volume: 1,000 units.

- Tooling: Aluminum Mold: $4,500.

- Production: $2.50/part (material + machine time + labor).

- Amortized Tooling Cost: $4,500 / 1,000 = $4.50/part.

- Total Landed Per-Part Cost: $7.00.

This provides a true injection molded part for market testing at a viable cost, where the same part from CNC machining might cost $30+ each.

Case Studies: Successful Custom Plastic Parts

Case Study 1: Medical Device Startup – Regulatory Pathway

A startup developing a novel respiratory therapy device needed 300 fully functional units for a pivotal clinical trial. The parts needed to be sterile and made from medical-grade PC. Using CNC machining was cost-prohibitive ($150/unit), and production tooling was premature. They opted for small batch injection molding with an aluminum mold. They received FDA-approved, injection-molded parts in 5 weeks at a per-unit cost of $22. This allowed them to conduct the trial, gather crucial data, and secure Series B funding based on real-world results, all before committing to a $60,000 production steel mold.

Case Study 2: Consumer Electronics – Crowdfunding Launch

A company designing a smart home sensor launched a Kickstarter campaign. They needed 2,500 units to fulfill backer rewards. They used rapid aluminum tooling to produce the two main housing components in colored ABS. The molds were cut in 3 weeks, and all parts were produced and shipped within the 8-week campaign fulfillment window. The professional quality of the injection molded parts built brand credibility and positive reviews, directly fueling their move into retail channels, where they then invested in high-cavity steel molds.

Conclusion

Small batch injection molding is not a compromised version of mass production; it is a distinct, strategic manufacturing phase designed for innovation and agility. By leveraging advanced but cost-effective tooling technologies like aluminum and soft-steel molds, companies can now access the gold standard of part quality—true injection molding—at volumes and price points that were previously impossible. This capability transforms product development from a high-stakes gamble into a manageable, iterative process. Whether you are validating a design, testing a market, or managing a specialized low-volume product line, small batch molding provides the critical bridge between idea and scalable reality.

FAQ

What is the difference between small batch injection molding and 3D printing for prototypes?

3D printing excels at form and fit prototypes, extremely complex geometries, and single-digit quantities with speed. Small batch injection molding is for functional prototypes and low-volume production. It provides superior material properties, surface finish, and true production-grade parts for testing under real-world conditions. It is the next step after 3D printing validates the basic design.

Can I use my small batch aluminum mold for future production runs?

Yes, absolutely. This is a key benefit. An aluminum mold is a physical asset. You can store it and run future batches whenever needed—for spare parts, additional market testing, or as a bridge while a production steel mold is being built. This makes it perfect for products with uncertain or intermittent demand.

How does the quality of parts from an aluminum mold compare to a steel mold?

The part quality—dimensional accuracy, surface finish, and material properties—is virtually identical when the mold is new. The difference lies in longevity and consistency over hundreds of thousands of cycles. For a run of a few thousand parts, you should see no quality difference. The process parameters (temperature, pressure) are the same.

Are there material limitations with small batch tooling?

Aluminum molds are not recommended for highly abrasive materials (e.g., glass-filled nylons or plastics with mineral fillers) as they will cause accelerated wear. They are also less suitable for high-temperature plastics (e.g., PEEK) that require very high mold temps, which can soften aluminum. For most commodity and engineering plastics (ABS, PC, PP, unfilled Nylon), aluminum is perfectly suitable.

What happens if I need to make a design change after the mold is made?

With aluminum tooling, modifications are possible but come with cost and time. Simple changes (adding a rib, modifying a hole) can often be machined into the existing aluminum mold. Major changes may require re-cutting sections of the mold or making new inserts. This is why thorough DFM and prototyping are crucial before cutting any mold, regardless of material.

Contact Yigu Technology for Custom Manufacturing.

Unlock the potential of agile product development with Yigu Technology's specialized small batch injection molding services. We empower innovators and businesses to bring custom plastic parts to market faster and with less risk. Our expertise lies in selecting and crafting the perfect rapid tooling solution—whether aluminum, soft steel, or insert molds—to match your precise volume, budget, and timeline. From proactive Design for Manufacturability (DFM) analysis to efficient production and quality assurance, we provide an end-to-end partnership for your prototype, bridge, and low-volume manufacturing needs. Contact Yigu Technology today to get a competitive quote and see how we can turn your design into high-quality, injection-molded reality.