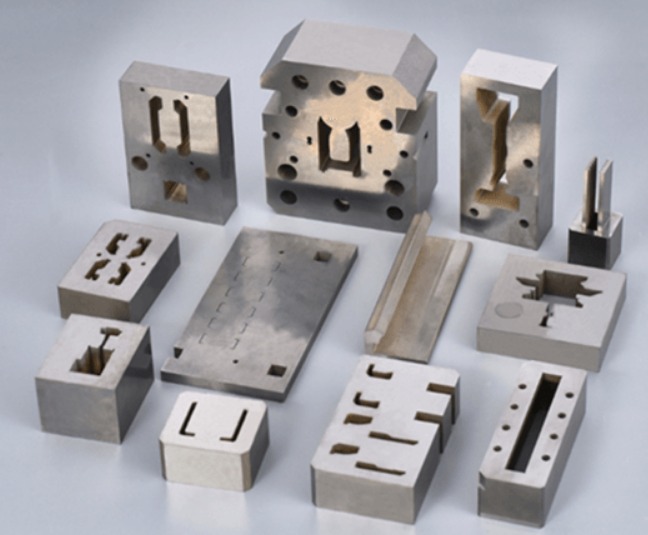

In the world of injection molding and die casting, the quality of the final product is directly dictated by the quality of the tool that forms it. Precision Mold Parts—the cores, cavities, inserts, ejector pins, and guide components—are the heart of that tool. These are not just pieces of metal; they are high-stakes engineering components where microscopic accuracy translates to flawless part production, minimal downtime, and maximum mold longevity. For mold makers, tool engineers, and production managers, mastering the creation and integration of Precision Mold Parts is non-negotiable. This guide delves into the exacting standards, advanced materials, and meticulous processes required to produce these critical components, ensuring your molds perform with reliability and precision for millions of cycles.

What Qualifies a Component as a Precision Mold Part?

A Precision Mold Part is defined by its function, not just its tolerance. It is any component within a mold assembly whose dimensional accuracy, geometric perfection, surface finish, and material integrity are critical to:

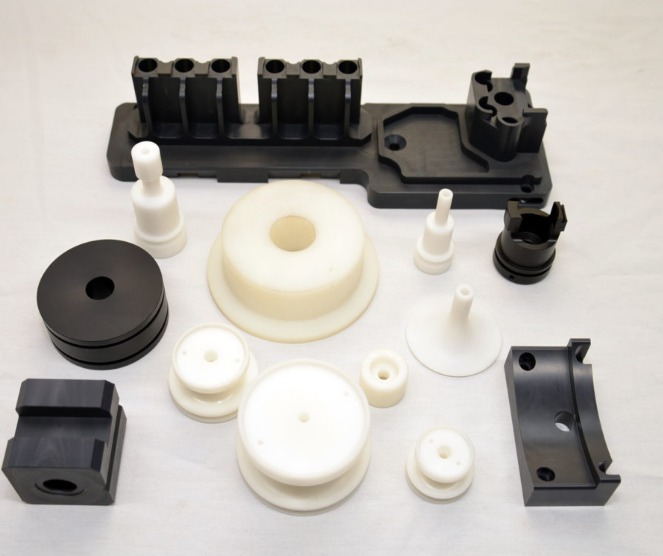

- The Form of the Final Plastic/Metal Part: Core and cavity inserts directly create the part geometry.

- The Function and Durability of the Mold Itself: Guide pillars/bushes, interlocks, and ejector systems ensure smooth, repeatable operation.

- The Efficiency and Quality of the Molding Process: Hot runner nozzles, valve gates, and temperature control inserts manage the flow and cooling of material.

If a part's failure or deviation causes defective production, stoppages, or mold damage, it qualifies as "precision."

Which Tolerances Are Typically Required?

Tolerances for Precision Mold Parts are dramatically tighter than for general machining. They are often specified in microns (µm) or ten-thousandths of an inch (0.0001").

- Forming Surfaces (Cores/Cavities): Critical dimensions often require tolerances of ±0.005 mm (±0.0002") or tighter, especially for optical lenses, medical devices, or connectors.

- Fit and Function Areas: Guide pillars, ejector pins, and core backs typically have tolerances of ±0.0025 mm to ±0.01 mm (±0.0001" to ±0.0004") to ensure perfect sliding fits without play or binding.

- Location and Alignment: Dowel pin holes and interlocks may require true position tolerances within 0.005 mm (0.0002") to guarantee perfect alignment of mold halves and inserts.

What Materials Ensure Long Tool Life?

Material selection balances wear resistance, toughness, polishability, and thermal properties.

- Tool Steels (Pre-Hardened): P20 (1.2311) and 718 (1.2738) are common for high-volume production molds. They offer good machinability and polishability at ~30-35 HRC hardness straight from the mill.

- Through-Hardening Steels: H13 (1.2344) is the king of die casting and high-heat injection molds. It's heat-treated to 48-52 HRC, offering excellent hot hardness and thermal fatigue resistance.

- Stainless Steels: S136 (1.2083) or 420SS are used for corrosion-resistant molds (e.g., for PVC, medical, or food-grade materials). They can be hardened and achieve a superb mirror polish.

- Hard Metals & Carbides: For ultra-high-wear applications like micro-molding or abrasive filled plastics, tungsten carbide inserts are used. They are extremely hard (70+ HRC) and wear-resistant but brittle and expensive.

How to Select the Right Machining Strategy?

Sequencing operations correctly is vital to manage stress and maintain accuracy.

- Rough Machining: Remove bulk material using stable, high-MRR strategies, leaving a uniform stock allowance (e.g., 0.5mm) for finishing.

- Stress Relieving (If Required): After roughing, a low-temperature stress relief cycle can minimize subsequent distortion during heat treatment or fine finishing.

- Semi-Finishing: Further refine geometry closer to final dimensions.

- Heat Treatment (If Applicable): Performed before final finishing to achieve target hardness.

- Fine Finishing: The most critical phase. Uses High-Speed Machining (HSM) with small stepovers, sharp tools, and rigid setups to achieve final dimensions and surface finish.

- Abrasive Processes: Electrical Discharge Machining (EDM) for complex geometries, deep ribs, or hardened steels. Grinding for achieving ultra-precise flatness, parallelism, and surface finish on guide components.

What Role Does Heat Treatment Play?

Heat treatment transforms the steel's microstructure to achieve desired properties.

- Through-Hardening (Quench & Temper): Used for H13, S136, etc. Heats steel to austenitizing temperature, quenches it rapidly to form hard martensite, then tempers it to reduce brittleness and achieve the target hardness-toughness balance. Distortion is inevitable, so significant finishing stock must be left post-HT.

- Nitriding (Surface Hardening): Diffuses nitrogen into the surface of finished or near-finished parts (like ejector pins, cores). Creates a super-hard, wear-resistant case (~0.1mm deep) at low temperatures (~500°C) that minimizes distortion. It does not improve core toughness.

How to Achieve Superior Surface Finishes?

Surface finish affects part release, cosmetics, and wear.

- Machined Finish: Using fine stepovers, high spindle speeds, and specialized ball-nose end mills can achieve finishes of Ra 0.2 - 0.4 µm (8-16 µin).

- Hand Polishing: The traditional art. Progressing through finer grits of diamond compound or stone to achieve SPI grades (e.g., A-1 for a true optical mirror finish). It is labor-intensive and skill-dependent.

- Abrasive Flow Machining (AFM): Excellent for uniform finishing of complex geometries and difficult-to-reach areas, producing a consistent, non-directional finish.

- EDM Finish: The final skim cut with a fine electrode and low power settings can produce excellent, reproducible finishes on hardened steel.

What Inspection Equipment Guarantees Accuracy?

"Precision" must be measured, not assumed.

- Coordinate Measuring Machine (CMM): The workhorse for 3D dimensional inspection. A high-precision CMM with a scanning probe can verify complex free-form surfaces against CAD data.

- Optical Comparators / Vision Systems: Ideal for fast, 2D profile inspection of small, flat components like ejector pins.

- Surface Roughness Tester: Quantifies finish with parameters like Ra, Rz, and Rmax.

- Roundness/Form Testers: For verifying the cylindricity and straightness of pins, sleeves, and cores.

- Hardness Testers (Rockwell C): To confirm heat treatment results.

What Coatings Extend Durability?

Applied to finished parts, coatings drastically improve performance.

- Physical Vapor Deposition (PVD): Coatings like TiN, TiCN, CrN, or DLC (Diamond-Like Carbon). They provide a thin (1-4µm), extremely hard, low-friction layer that reduces wear, corrosion, and sticking (e.g., for aluminum molding). They do not change part dimensions significantly.

- Polytetrafluoroethylene (PTFE) Impregnation: Often combined with nickel plating, it creates a permanent, low-friction surface to prevent galling on sliding components.

- Anodizing: For aluminum mold components (rare in precision parts), provides a hard, corrosion-resistant oxide layer.

How to Integrate Precision Parts into Full Mold Assembly?

The final test of precision is flawless integration.

- Thermal Stabilization: Allow all components to acclimate to the mold shop temperature (e.g., 20°C ±1°C) before final fitting.

- Selective Fitting/"Match-Marking": Critical pairs (e.g., core/cavity) are often machined and fitted as a set, with unique match marks to ensure they are never mixed.

- Clean Room Protocols: Assembly should occur in a clean, controlled environment to prevent contamination from dust, which can impede fits and damage surfaces.

- Stepwise Assembly and Verification: Assemble in logical steps, checking function (e.g., sliding fit, alignment) at each stage. Use precision granite squares, dial indicators, and feeler gauges for final verification of shut-offs and parallelism.

Conclusion

The creation of Precision Mold Parts is a symphony of advanced materials science, state-of-the-art machining, meticulous metrology, and skilled craftsmanship. It demands a process-oriented mindset where every step—from selecting the right H13 steel and planning the machining sequence to applying a CrN coating and performing a final CMM scan—is controlled and validated. Investing in these components is an investment in the mold's total performance: reduced downtime, consistent part quality, and an extended production lifespan that delivers a superior return on investment. For manufacturers aiming for excellence in molding, mastering the art and science of Precision Mold Parts is the ultimate competitive edge.

FAQ on Precision Mold Parts

What is the most common cause of premature failure in precision mold parts?

Improper heat treatment is a leading cause. This includes insufficient hardening (low wear resistance), excessive hardening without proper tempering (brittleness leading to cracking), or distortion during treatment that wasn't accounted for in machining stock allowance.

Can you repair a damaged precision core or cavity?

Yes, but it is complex and costly. Techniques include welding with specialized mold repair alloys followed by meticulous re-machining, re-heat treatment, and re-polishing. Often, the cost and risk approach that of making a new component, especially for hardened steels.

How does the choice between EDM and milling affect the final part?

Milling with sharp carbide tools typically produces a better surface integrity with less risk of a brittle "recast layer." EDM is indispensable for complex shapes but leaves a thin, hard, and often micro-cracked surface that usually requires subsequent polishing or abrasive removal to ensure durability.

What is "mirror polish" and how is it measured?

A mirror polish refers to an SPI #1 (A-1) finish, essentially free of visible scratches under 40x magnification. It is measured subjectively by comparison to standard plates or quantitatively with a surface roughness tester, achieving an Ra value of < 0.012 µm (0.5 µin).

Why is pre-hardened steel like P20 so popular if it's softer?

P20 offers an excellent balance. It can be machined to final dimensions in its pre-hardened state (~30 HRC), eliminating the distortion risks and extra steps of heat treatment. For many high-volume injection molding applications (millions of cycles), its hardness and polishability are perfectly adequate, making it a cost-effective and reliable choice.

Contact Yigu technology for custom manufacturing.

At Yigu Technology, we specialize in the end-to-end creation of mission-critical Precision Mold Parts. Our vertically integrated process combines advanced CNC machining, EDM, grinding, and heat treatment under one roof, governed by a metrology lab equipped with high-precision CMMs and surface analyzers. We understand that a mold is only as good as its components, which is why we engineer every core, cavity, and guide component for absolute accuracy, durability, and seamless integration.

From design support to final inspection, we provide the certainty and quality your high-stakes molding projects demand.

Contact Yigu Technology today to discuss your precision component needs and receive a detailed technical consultation.